Automatic film alignment machine

An automatic alignment and film technology, which is applied to optics, instruments, and the photoplate making process of the pattern surface, can solve the problems of difficulty in realizing the alignment of the flexible circuit board and the film, cumbersome workpiece clamping work, and low processing efficiency. Achieve the effect of small footprint, high quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

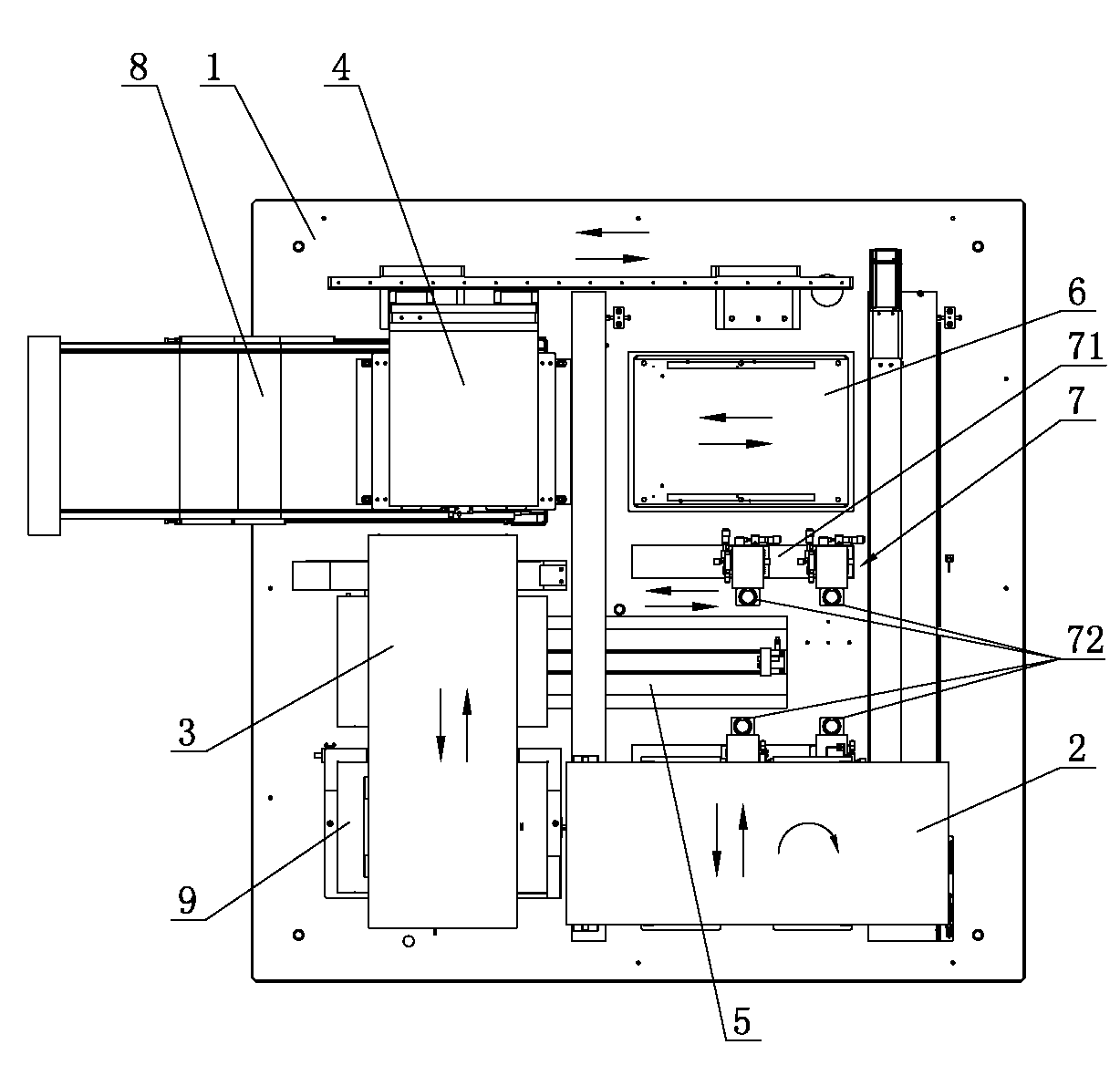

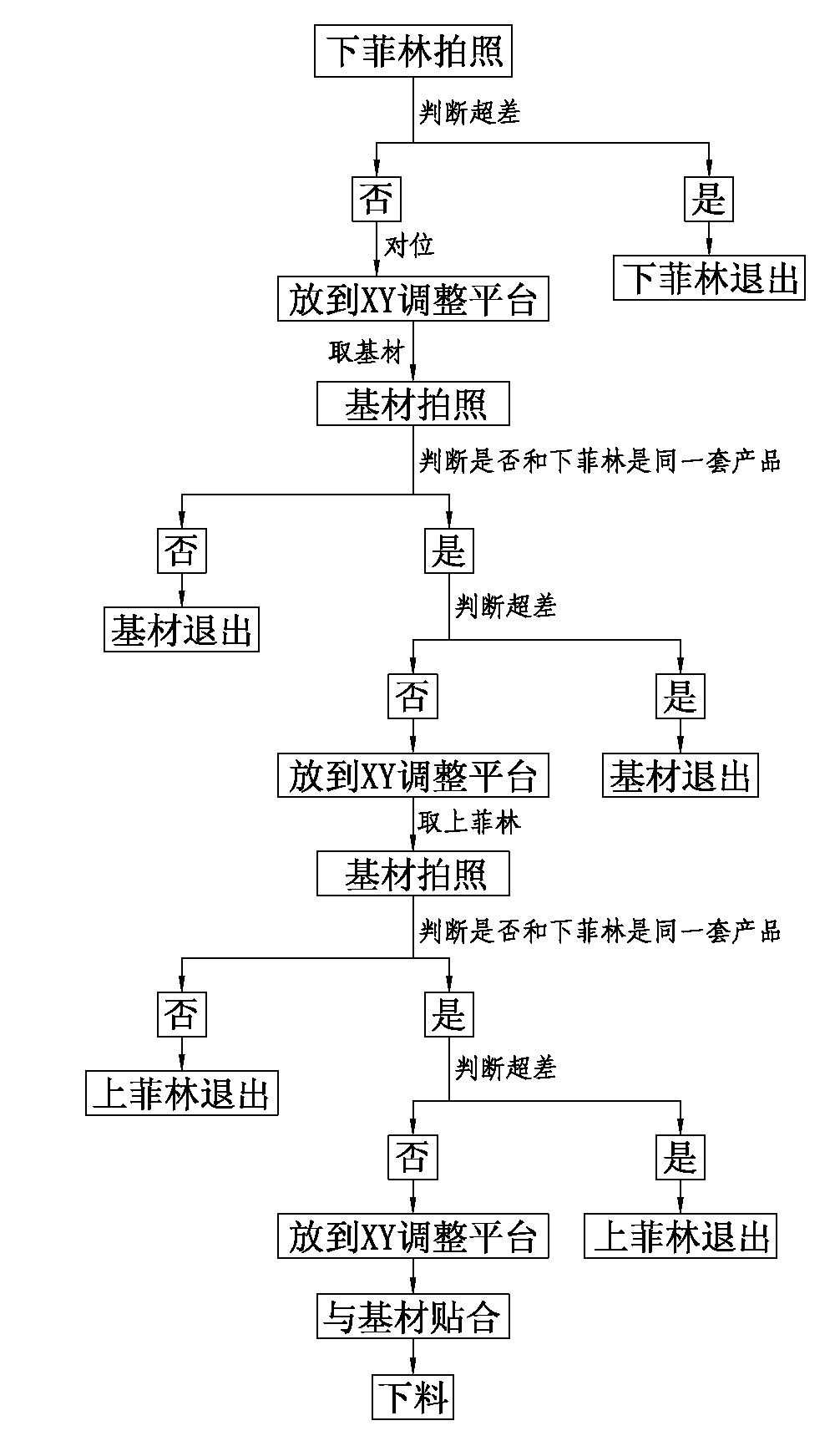

[0022] Such as figure 1 and figure 2 Shown, a kind of film automatic alignment machine, comprises frame 1, the film feeding manipulator 2 that is installed in frame 1, substrate material feeding manipulator 3, finished product unloading manipulator 4 and base material transmission unit 5, described The frame 1 is also equipped with an XY adjustment platform 6 and an alignment device 7. The XY adjustment platform 6 and the alignment device 7 are all located under the film feeding manipulator 2, and the film feeding manipulator 2 is placed on the XY adjustment platform. 6 and directly above the alignment device 7 to move back and forth longitudinally; the finished product unloading manipulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com