Method for compensating errors occurring in a production process

A production process and error technology, applied in the field of quality assurance in the production process, can solve problems such as time-consuming and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

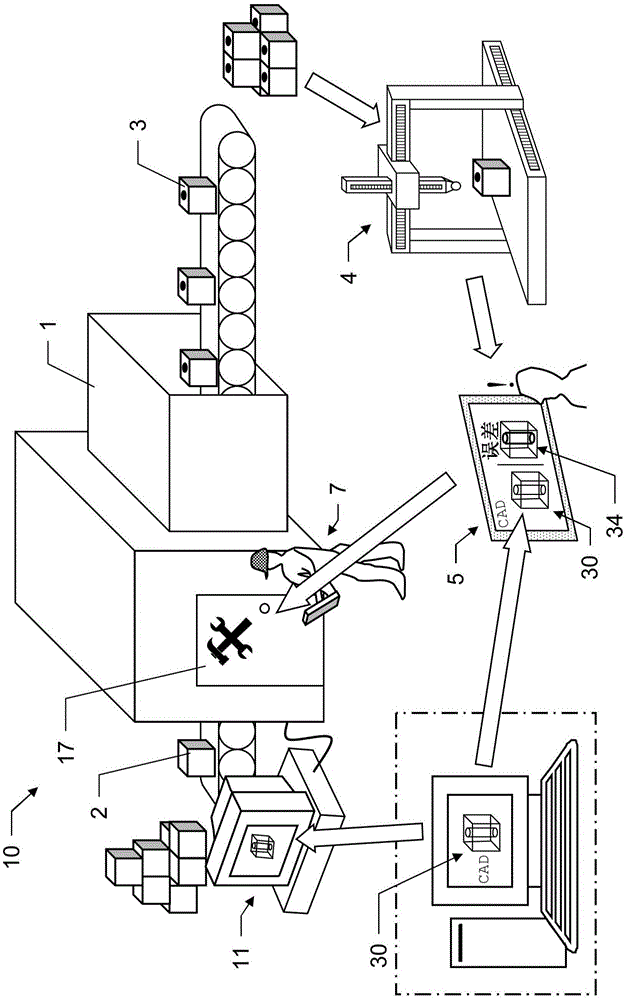

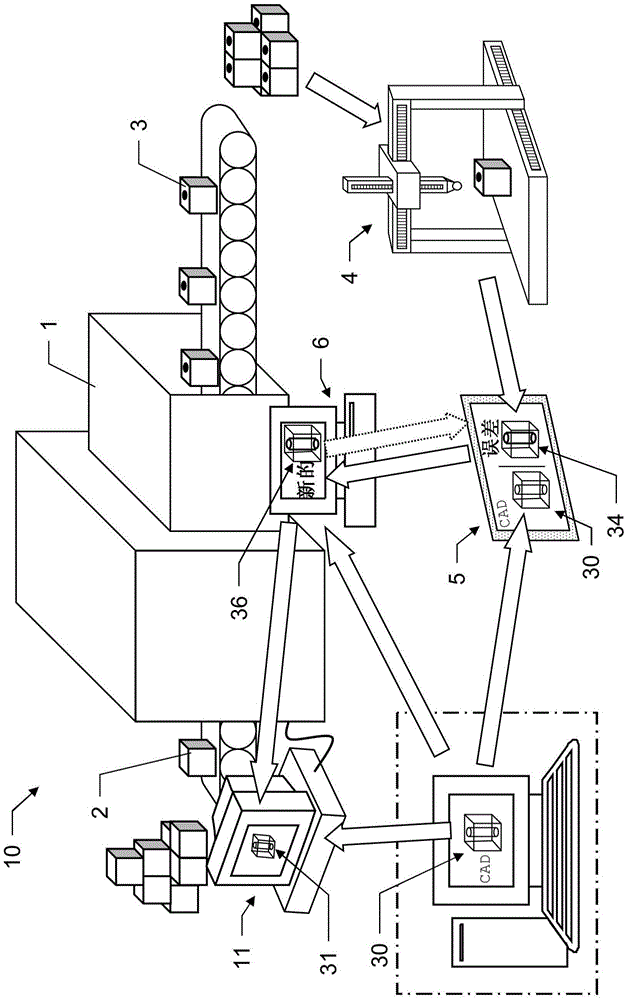

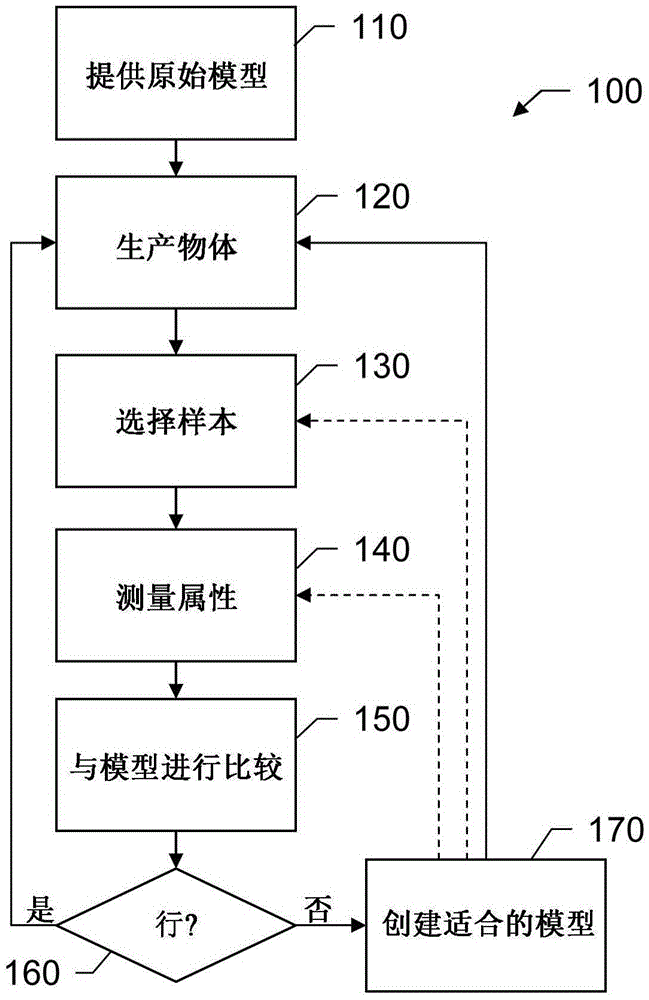

[0081] exist figure 1 In , a system known from the prior art for controlling the production process of an object 3 is shown. To produce the object 3 calibration data from the CAD model 30 are supplied to the manipulation unit 11 of the production assembly 10 . The production assembly comprises a production facility 1 which is controlled by a handling unit 11 and comprises at least one tool for producing an object 3 from a raw material 2 . After one or more objects 3 have been produced in the production facility 1 according to the CAD data 30 , samples of the objects 3 are taken for quality assurance reasons. These samples are then examined in a measurement facility 4 which measures a certain property of the samples. As shown in this exemplary illustration, the measurement facility 4 may include a coordinate measuring machine, and the measurements may include measurement space coordinates of the sample. Measurement data comprising information about the measured property is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com