Metal part grafting printing method

A technology of metal parts and software, applied in the field of 3D printing, can solve the problems of affecting production work, long time, high cost, etc., and achieve the effect of reducing cost and production efficiency, broadening the application field and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

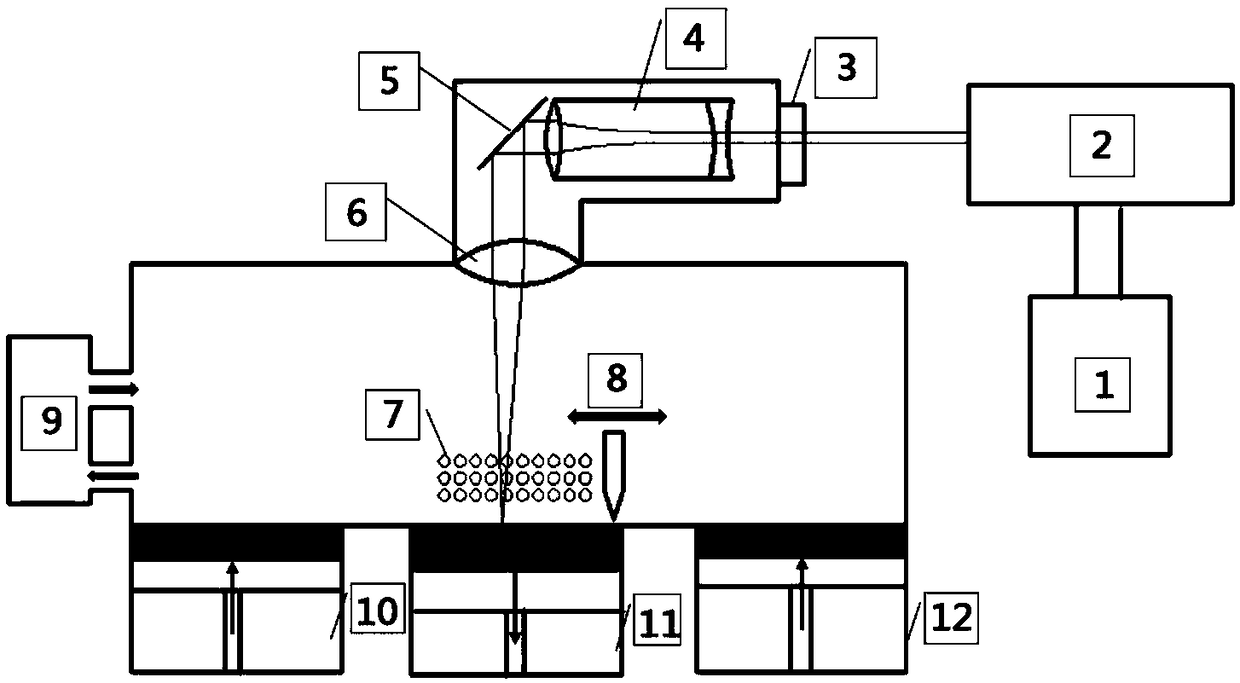

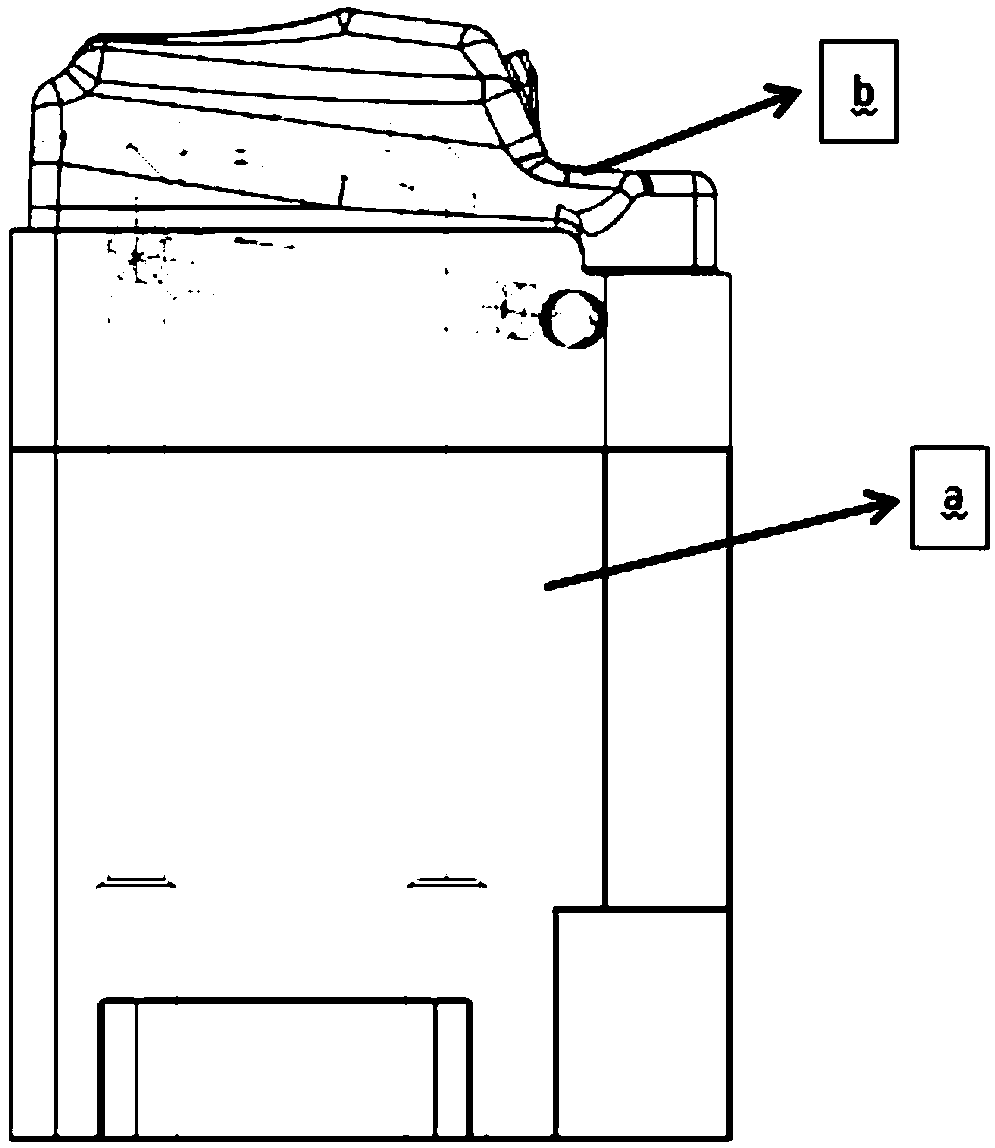

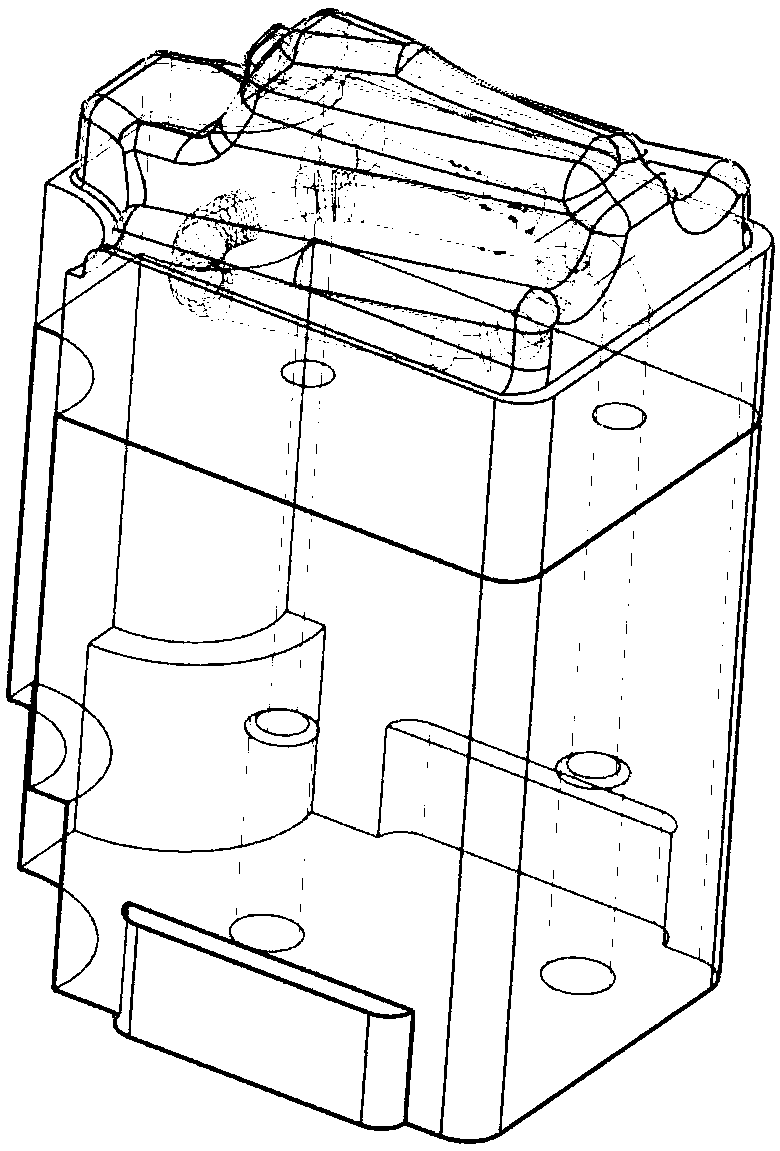

[0051] figure 1 Schematic diagram of the selective laser melting equipment provided for the embodiment of the present invention; figure 2 The front view of the model to be produced for the embodiment of the present invention (wherein a is the part to be machined, and b is the part to be manufactured by selective laser melting); image 3 An isometric side view of a model to be produced for an embodiment of the invention; Figure 4 Bottom view of the machined portion of the model to be produced for an embodiment of the invention; Figure 5 Top view of the desired machined portion of the model to be produced for an embodiment of the invention Figure 6 The top view of the laser sintering path of the desired machined part of the model to be produced for the embodiment of the present invention, wherein (1 is the path of laser sintering for the first time; 2 is the path of laser sintering for the second time; 3 is the path of laser sintering for the first time tertiary sintering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com