Deep-concave strip mine production model system

A model system, technology for open pit mines, applied in teaching models, educational appliances, instruments, etc., can solve problems such as inability to adjust the mining site, inability to improve, and complex engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

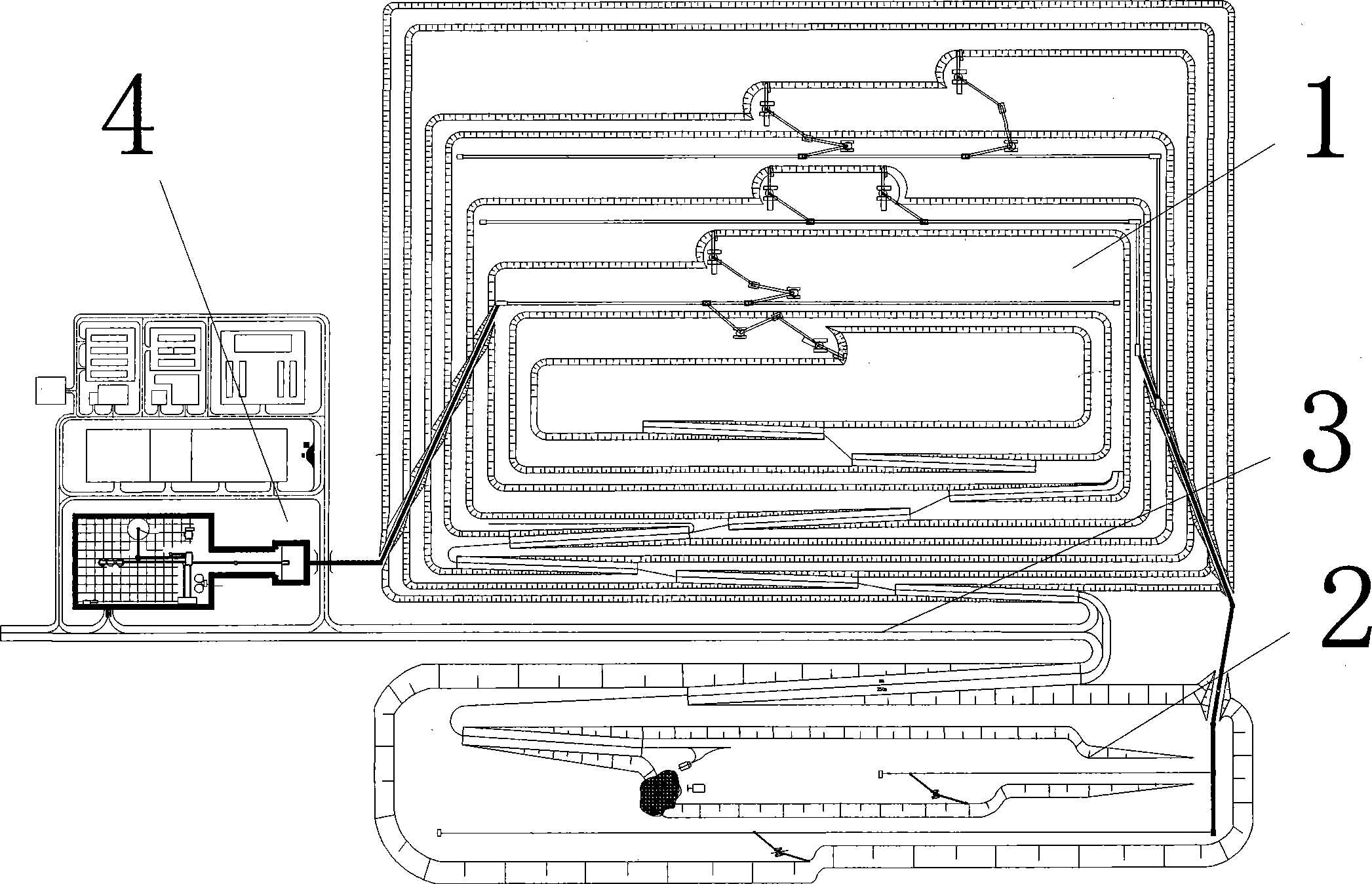

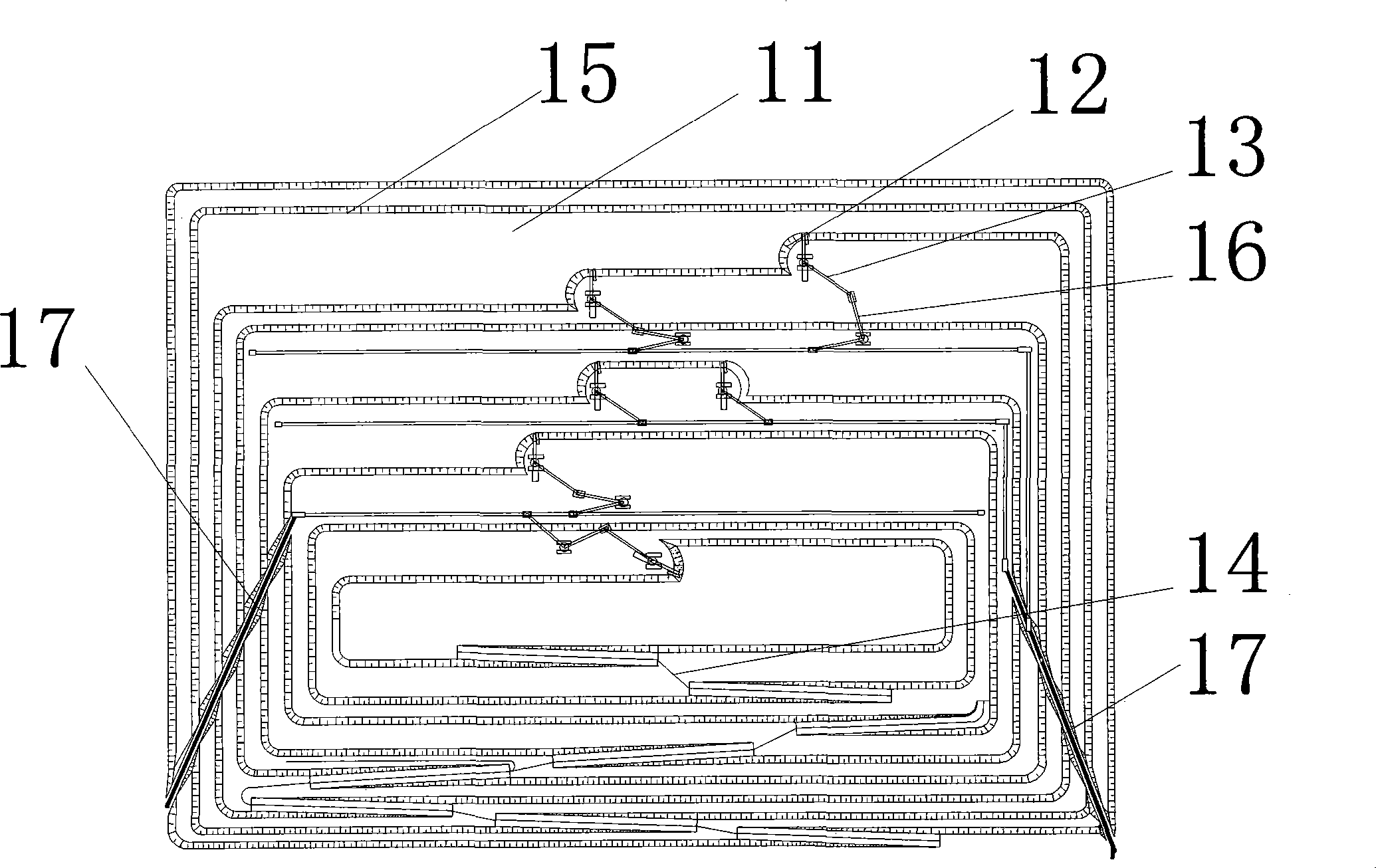

[0027] Embodiment 1: Experimental model of deep concave open pit mine with single bucket vehicle mining process;

[0028] see figure 2 As shown in the figure, it is a schematic top view of the model of the deep concave open-pit stope of the present invention. The deep-concave open-pit stope has a stope depth of 80-100 m, the coal seam 11 is arranged in a stepped shape, and the height of the stepped slope surface 15 is 10 m. The slope angle of the step is 65°, and the width of the working plate is 42m.

[0029] An inclined transport channel 14 is set on the top moving stope line of the deep-concave open-pit stope 1, along which the vehicle runs; the length of the inclined transport channel 14 is 125m, the longitudinal gradient is 8%, and the road width is 10m ; Slope distance 30m.

[0030] A mining face 12 is set on the step, and the bucket excavator 13 and the belt vehicle 16 collect coal at this position; a belt conveyor 17 is connected to the step of the deep concave open...

Embodiment 2

[0039] Embodiment two: single bucket-automobile-tape semi-continuous mining process deep concave open pit experimental model;

[0040]In this embodiment, the depth of the stope is 200m; the slope angle of the steps is 65°; the length of the inclined transport channel is 125m, the longitudinal slope is 8%, and the width of the road for vehicle ground transportation is 10m; The 12 steps in the lower part of the stope are equipped with four semi-fixed crushing stations, one for every three steps, and the main transport belts are set along the inclined direction in the western fixed gang to undertake the transportation of the four crushing stations respectively. The peeled material is transferred to the ground tape machine, and then the ground tape machine will transfer the peeled material to the tape machine of the southern dump for disposal. The main coal transport belt is set up in the eastern fixed gang, and a semi-fixed raw coal crushing station is set up every three coal min...

Embodiment 3

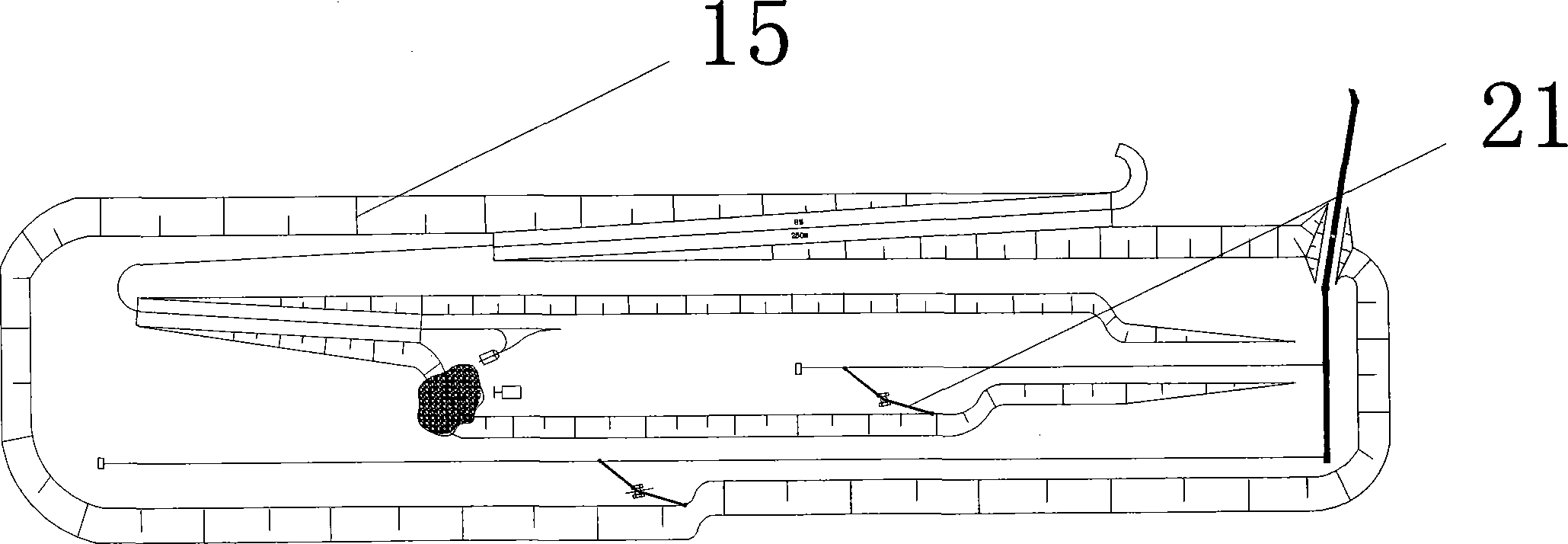

[0041] Embodiment 3: single bucket-vehicle mining process hillside open-pit mine experimental model;

[0042] In this embodiment, the vertical height of the hillside is 80m, the inclination is 20°; the length of the inclined transport channel is 125m, the longitudinal gradient is 8%, and the road width is 10m; Stope ratio: length: width = 2.5: The top-side transportation stope line is provided with an inclined transportation channel, which goes straight every three steps from bottom to top and then turns back.

[0043] In the present invention, the coal seam outcrop is below the level of 60m from the surface, the east-west trend, the coal seam dip angle is 6° and is nearly horizontal, the inclination direction is from north to south, and the horizontal thickness of the coal seam is 30m.

[0044] Every three peeling steps in the upper part are loess steps, forming a combined step, which can be directly excavated without blasting a bucket wheel excavator. The height of the combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Step height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com