Cross point welding sample multidirectional fatigue loading fixture

A fatigue loading and fixture device technology, applied in the fields of machinery and automobile manufacturing, can solve problems such as no occurrence, and achieve the effects of easy operation, ensuring neutrality, and ensuring the degree of clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

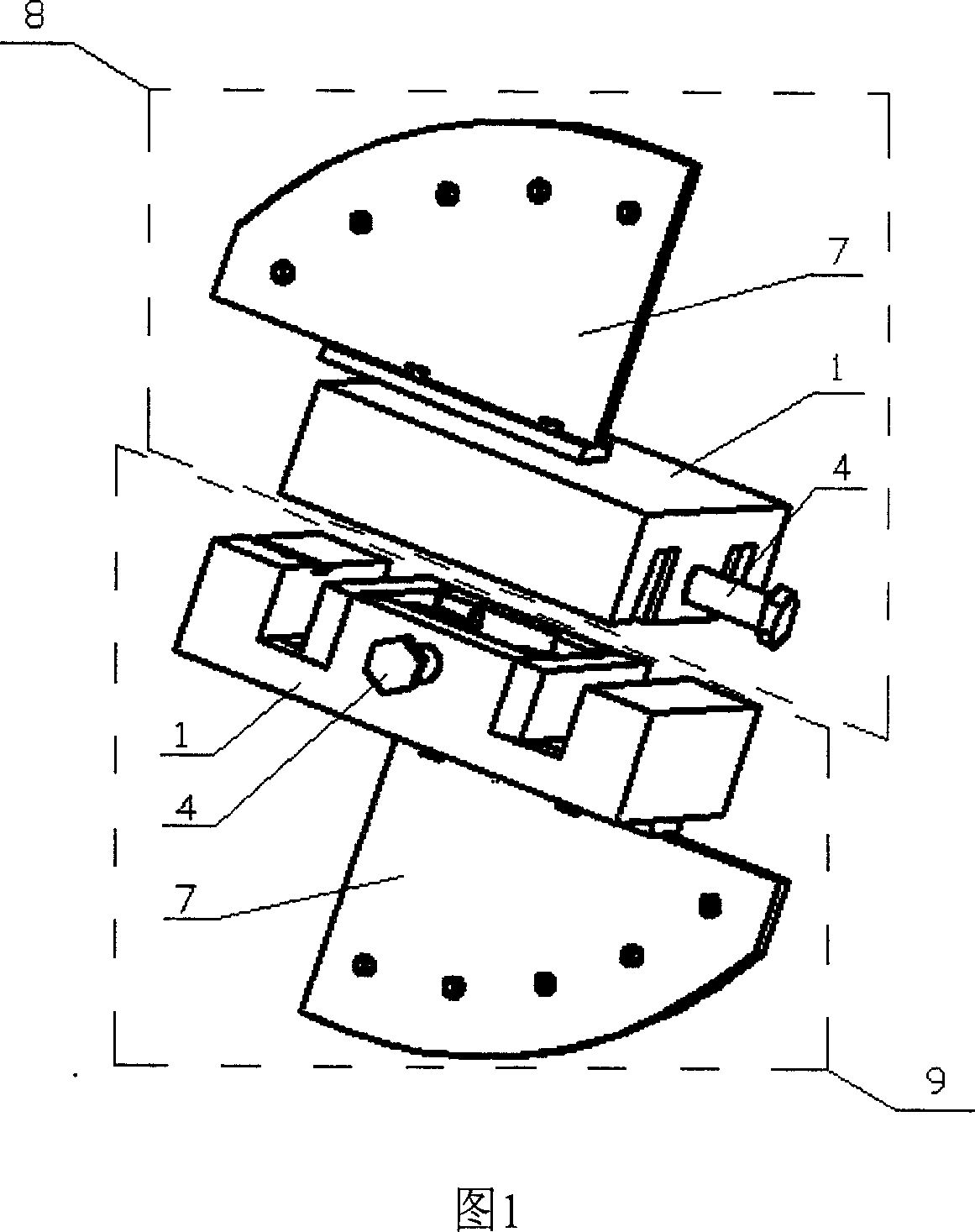

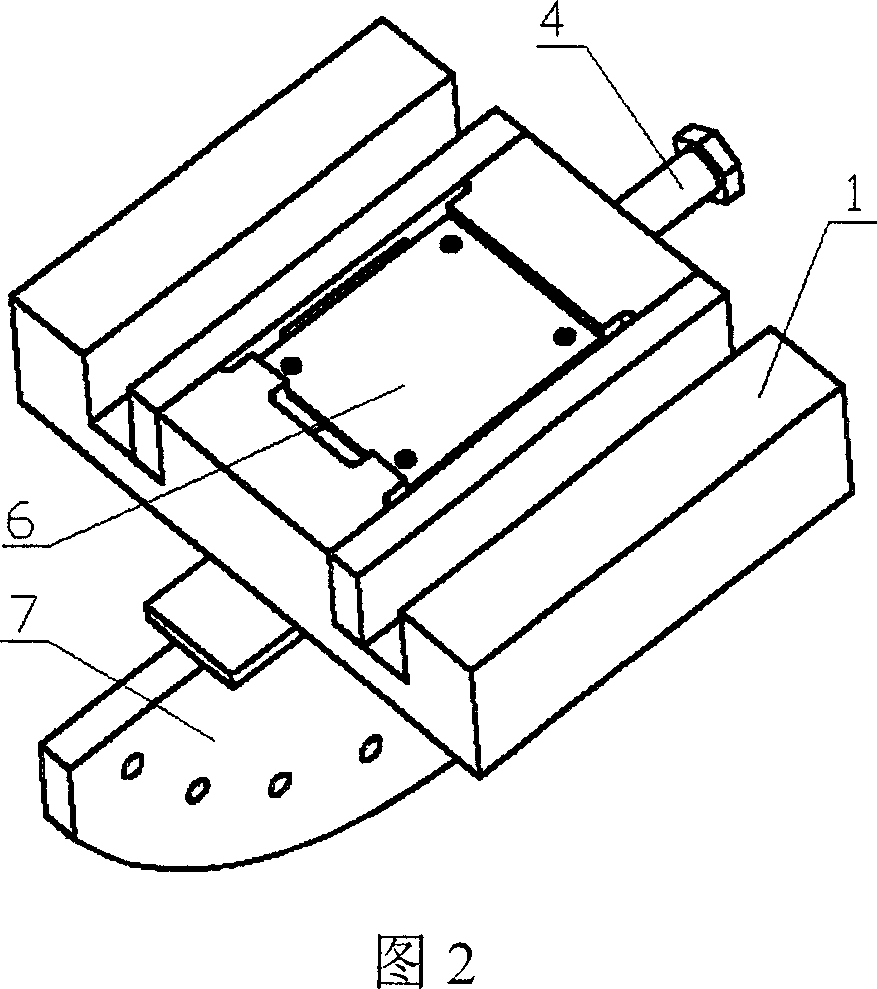

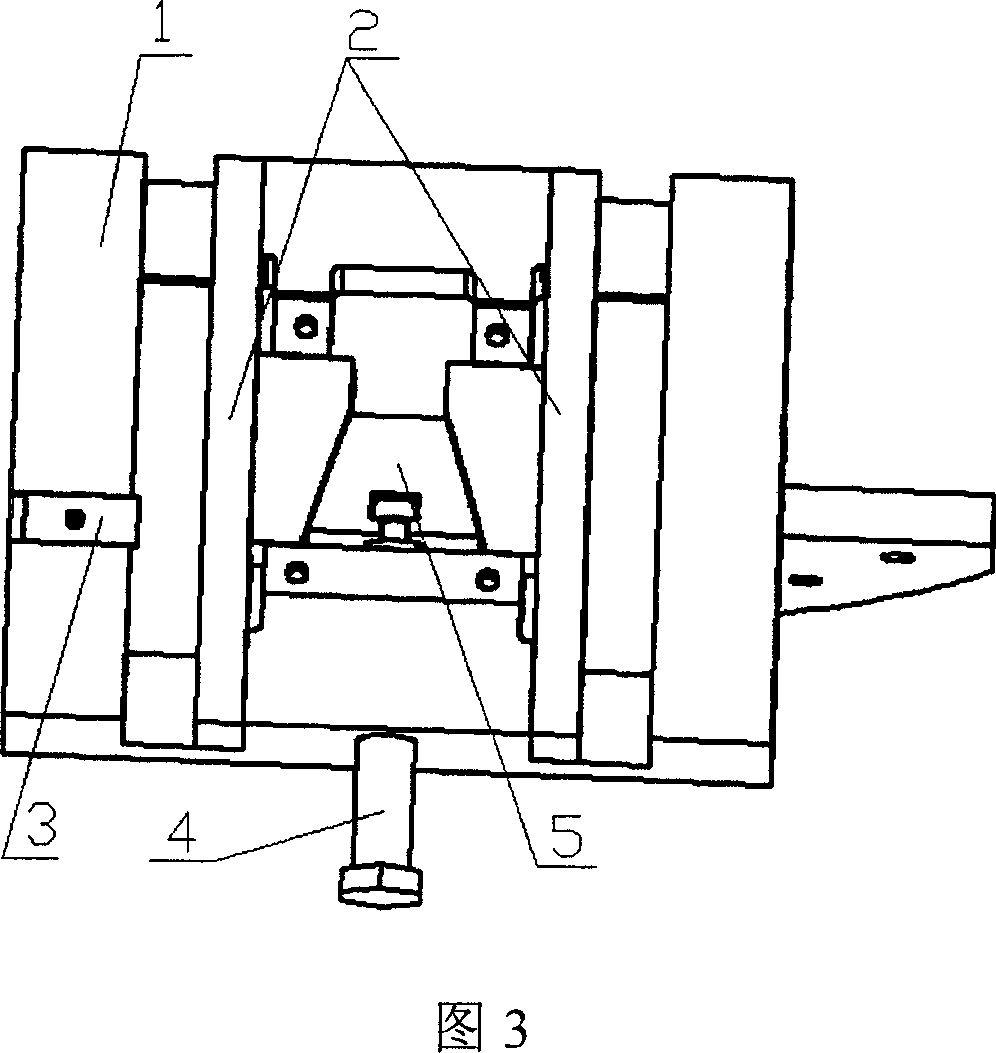

[0021] Hereinafter, embodiments of the present invention will be described in detail with reference to FIGS. 1 to 5.

[0022] This embodiment mainly includes an upper clamping body 8 and a lower clamping body 9, and the upper clamping body 8 and the lower clamping body 9 are two independent similar structures. Among them, the lower clamp body 9 mainly includes a base 1, a trapezoidal block 5, a wedge-shaped clamping block 2, a lock disc 7. An "H"-shaped groove is provided on the upper surface of the base 1, and the groove is opposite to the upper surface. The surface center lines are symmetrical, the trapezoidal block 5 and the wedge-shaped clamping block 2 are arranged in the groove, the center line of the trapezoidal block 5 coincides with the center line of the upper surface of the base 1, and the bottom surface of the trapezoidal block 5 is provided with a dovetail groove. A threaded transmission screw 4 is arranged on the side surface of the base 1 along the axis direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com