Direct driving type volume servo control power installation

A technology of servo control and power device, applied in the direction of fluid pressure actuating device, servo motor, steering steering with rudder, etc., can solve the problems of large amount of working medium, difficult disposal of waste medium, short service life, etc., and achieve low manufacturing cost , saving raw materials and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

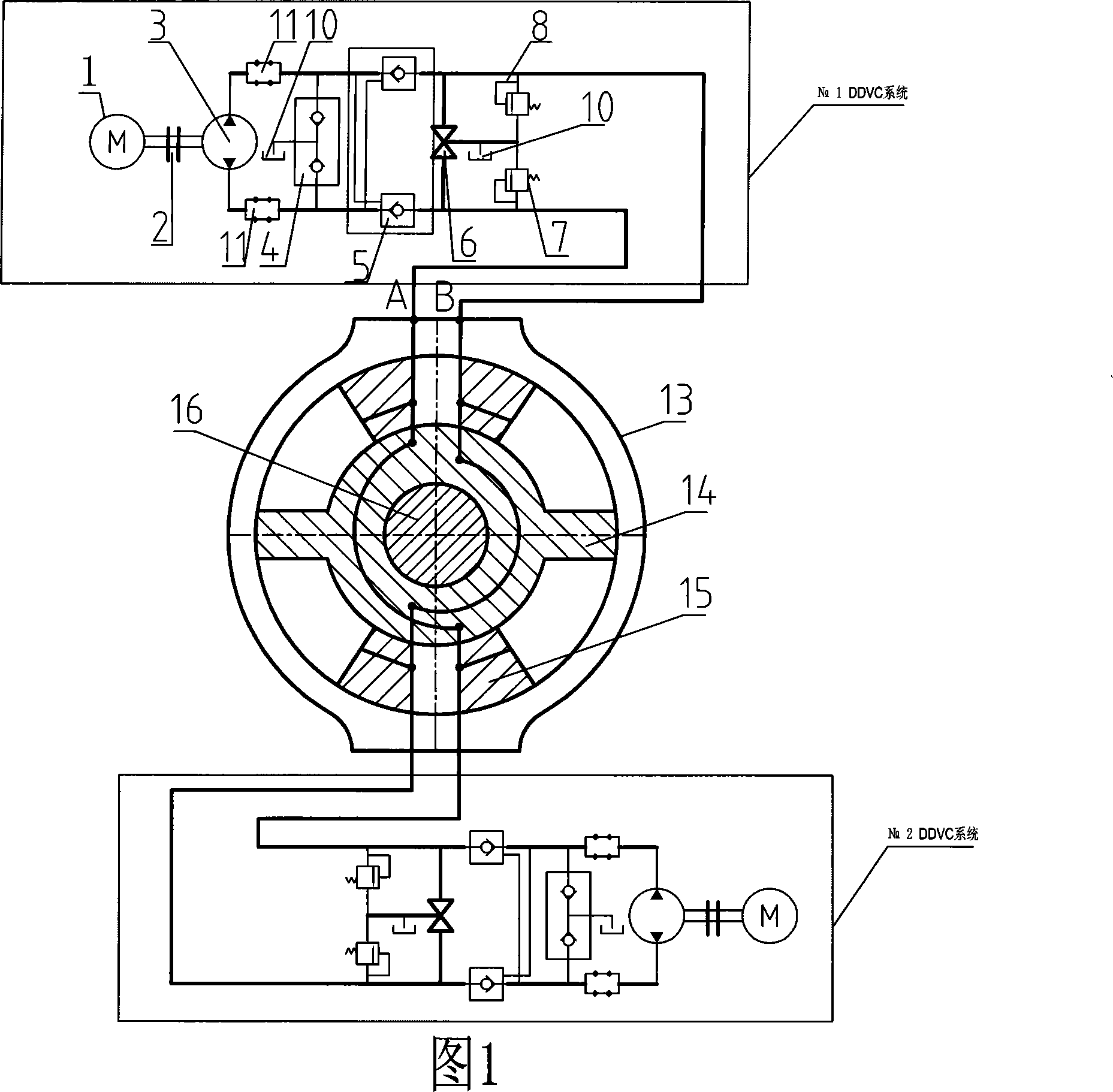

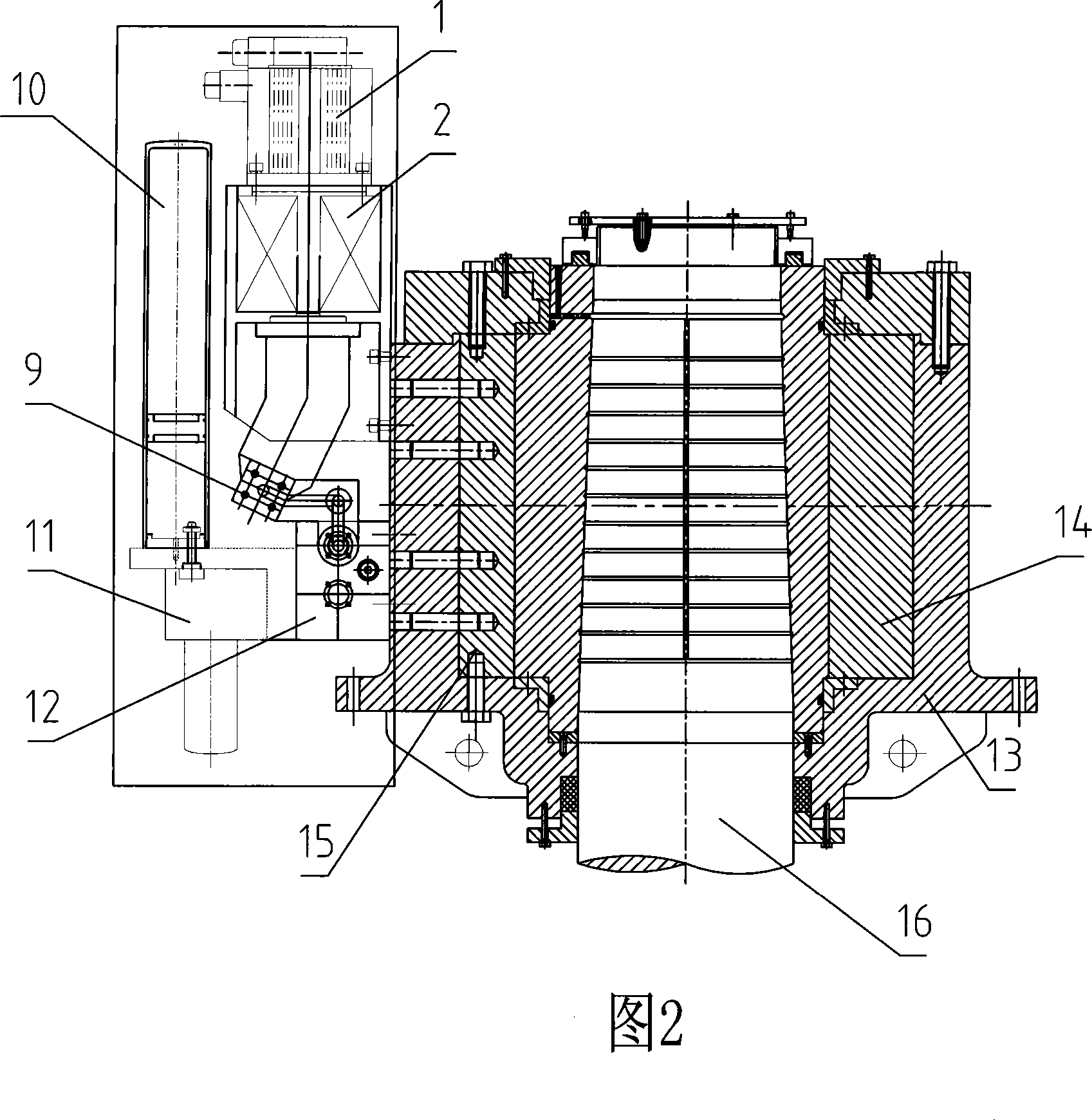

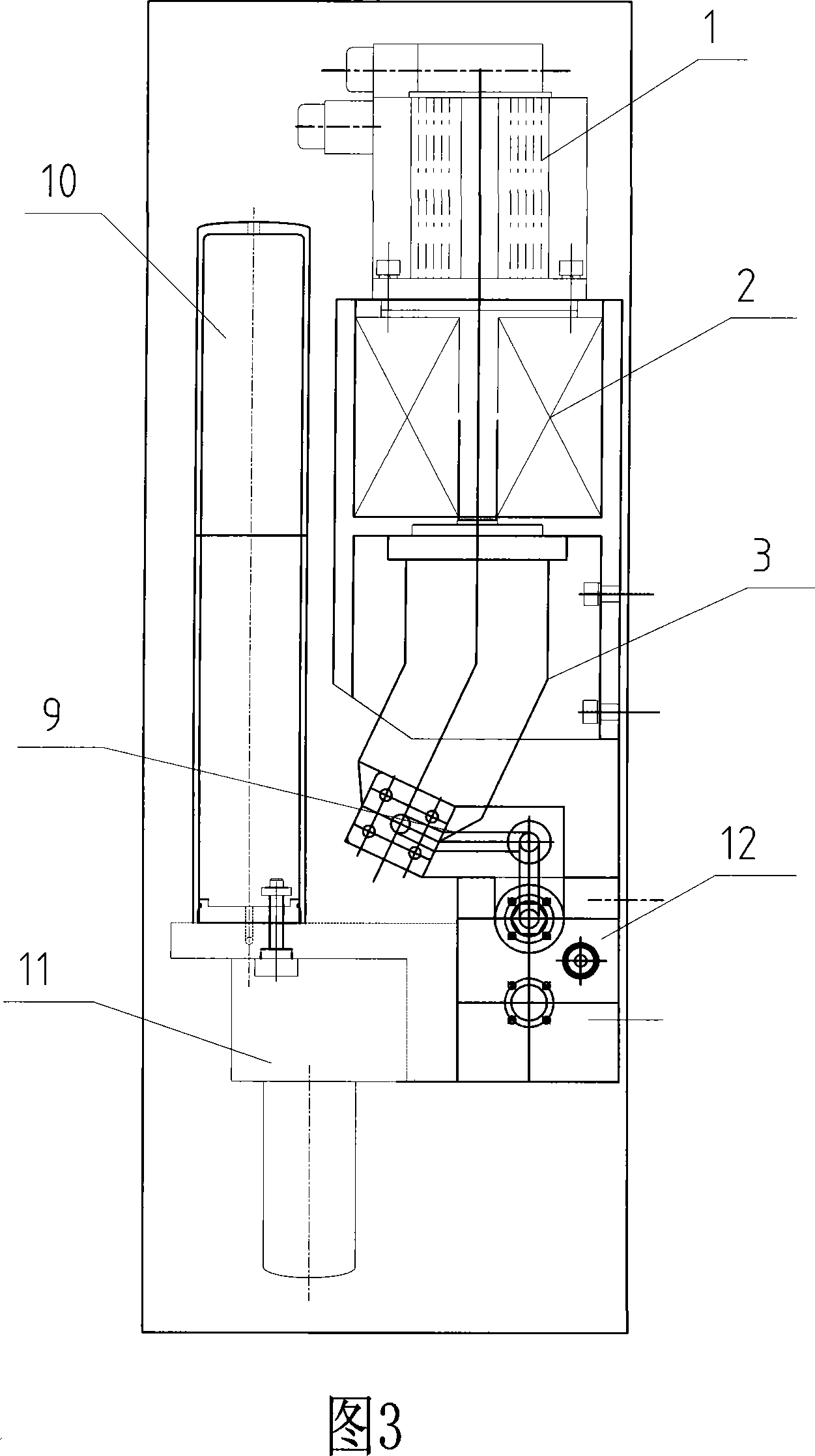

[0028] The specific embodiment of the present invention is as shown in the accompanying drawings; Take the control of the marine rotary vane steering gear as an example for further description; AC servo motor 1 is connected with bidirectional quantitative pump 3 through speed changer 2; ) is sealedly connected with the two inlets and outlets of the input end of the shuttle valve (4), and communicated with the pressure oil tank 10. Shuttle valve 4, lock valve 5, bypass valve 6, safety valve 7, 8; their oil passages are sealed and connected with connecting channels to jointly form an oil control unit, and the two interfaces A and B at the output end of the oil control unit are connected with the hydraulic actuator, that is, the marine Servo is connected. Since the AC servo motor 1 has the characteristics of stepless speed change, controllable direction change rotation, settable torque and position control, etc., its function is to realize the flow control, reversing control, pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com