High temperature-resistant polyacrylate pressure-sensitive adhesive emulsion and preparation method and application thereof

A polyacrylate and pressure-sensitive adhesive emulsion technology, which is applied in the direction of ester copolymer adhesives, adhesive types, rosin adhesives, etc., can solve the problem of easy residual adhesive, inability to completely replace, and unsatisfactory high temperature resistance and other issues, to achieve the effect of ensuring mechanical stability, cost saving, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The formula of high temperature resistant polyacrylate pressure sensitive adhesive emulsion is:

[0069] 80 parts of 2-ethylhexyl acrylate

[0070] Styrene 14 parts

[0071] Acrylic 4 parts

[0072] 2 parts hydroxyethyl acrylate

[0073] Polymerized rosin 15 parts

[0074] Allyloxy nonylphenol polyoxyethylene (10) ether 3 parts

[0075] 4 parts of melamine etherified resin

[0076] Potassium persulfate 0.4 parts

[0077] 4 parts ammonia water

[0078] 100 parts of water.

[0079] The preparation method comprises the following steps:

[0080] (1) Add 3 parts of allyloxy nonylphenol polyoxyethylene (10) ether and 40 parts of water into the emulsification kettle, stir to obtain a reactive emulsifier aqueous solution; dissolve 15 parts of polymerized rosin in 80 parts of acrylic acid-2- Ethylhexyl ester, 14 parts of styrene, 4 parts of acrylic acid and 2 parts of hydroxyethyl acrylate are mixed monomers, and the dissolved mixture is slowly added to the reactive emu...

Embodiment 2

[0087] The preparation method and conditions of the high-temperature resistant polyacrylate pressure-sensitive adhesive emulsion are as in Example 1, the consumption of polymerized rosin is reduced to 10 parts, and the amount of melamine methyl etherified resin is reduced to 3.5 parts to obtain a high-temperature resistant polyacrylate pressure-sensitive adhesive emulsion .

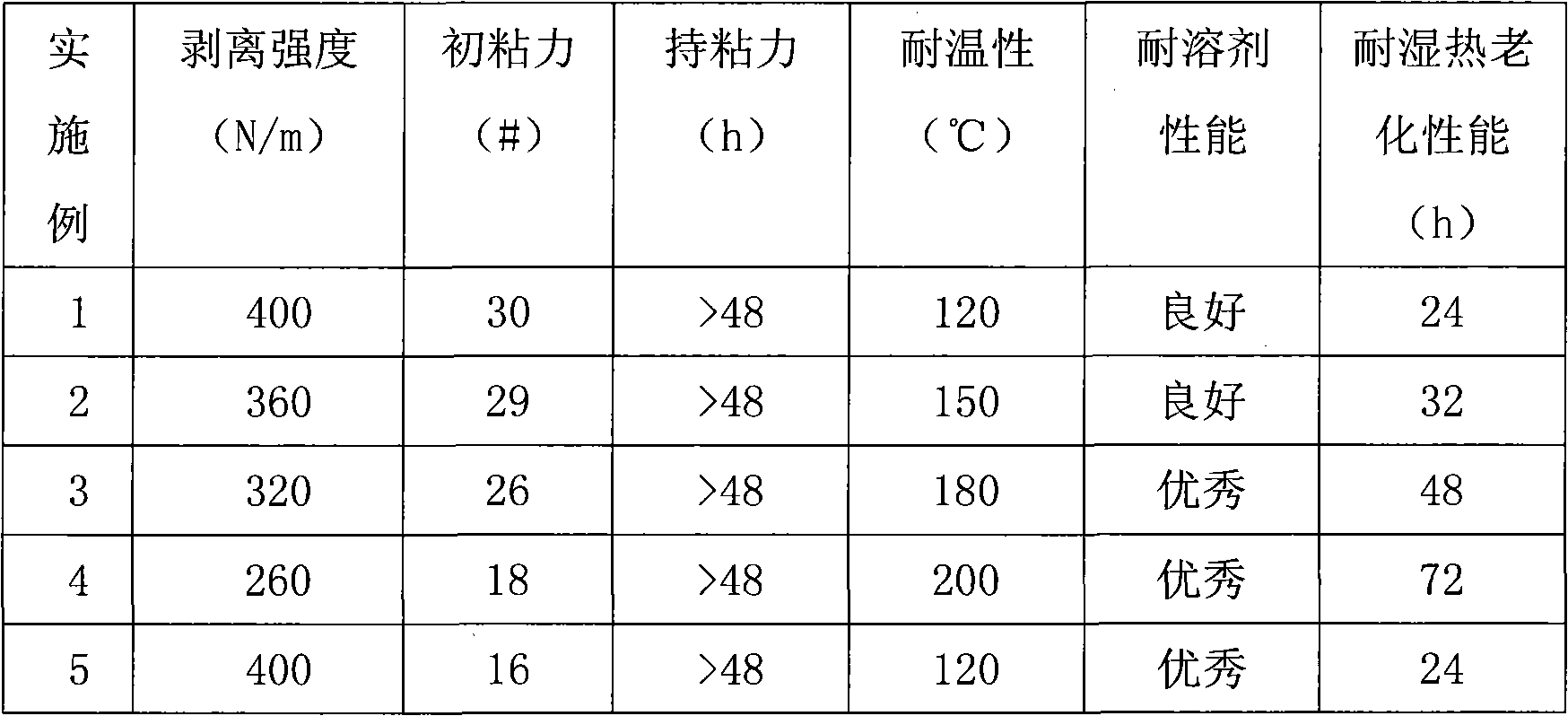

[0088] The obtained emulsion was prepared into a pressure-sensitive adhesive, as shown in Table 1: in the case of little change in mechanical properties, the temperature resistance of the pressure-sensitive adhesive increased to 150°C. Therefore, it can be seen that when the amount of polymerized rosin is reduced from 15 parts to 10 parts, the temperature resistance of the pressure-sensitive adhesive can be increased by 30°C.

Embodiment 3

[0090] The formula of high temperature resistant polyacrylate pressure sensitive adhesive emulsion is as follows,

[0091] 60 parts of butyl acrylate

[0092] 30 parts of 2-ethylhexyl acrylate

[0093] Methyl methacrylate 6 parts

[0094] Acrylic 4 parts

[0095] 2 parts hydroxyethyl acrylate

[0096] 7 parts polymerized rosin

[0097] Allyloxynonylphenol polyoxyethylene (10) ether ammonium sulfate 1 part

[0098] Aziridine derivative 1 part

[0099] Potassium persulfate 0.3 part

[0100] 4 parts ammonia water

[0101] 100 parts of water.

[0102] The preparation method comprises the following steps:

[0103] (1) Add 1 part of allyloxy nonylphenol polyoxyethylene (10) ether ammonium sulfate and 40 parts of water into the emulsification kettle, stir to obtain a reactive emulsifier aqueous solution; dissolve 7 parts of polymerized rosin in 60 parts of butyl acrylate ester, 30 parts of 2-ethylhexyl acrylate, 6 parts of methyl methacrylate, 4 parts of acrylic acid, and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Temperature resistance | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com