Repair welding clamp for lower body of light weight vehicle

A welding fixture and light-weight technology, which is applied in the field of repair welding fixtures for the lower body of light vehicles, can solve the problems of single positioning and single function of repair welding fixtures, achieve flexible production, reduce production costs, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution can also be realized through the following technical measures and the present invention will be further described below in conjunction with the accompanying drawings:

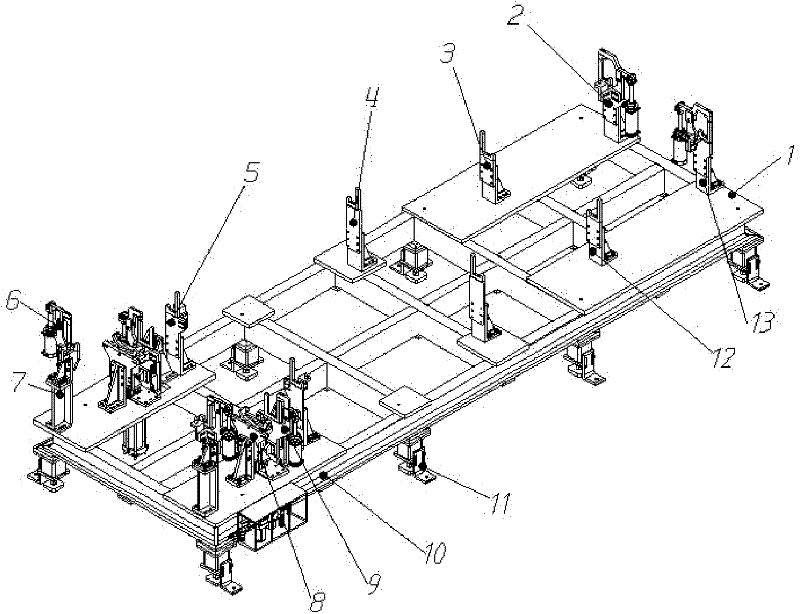

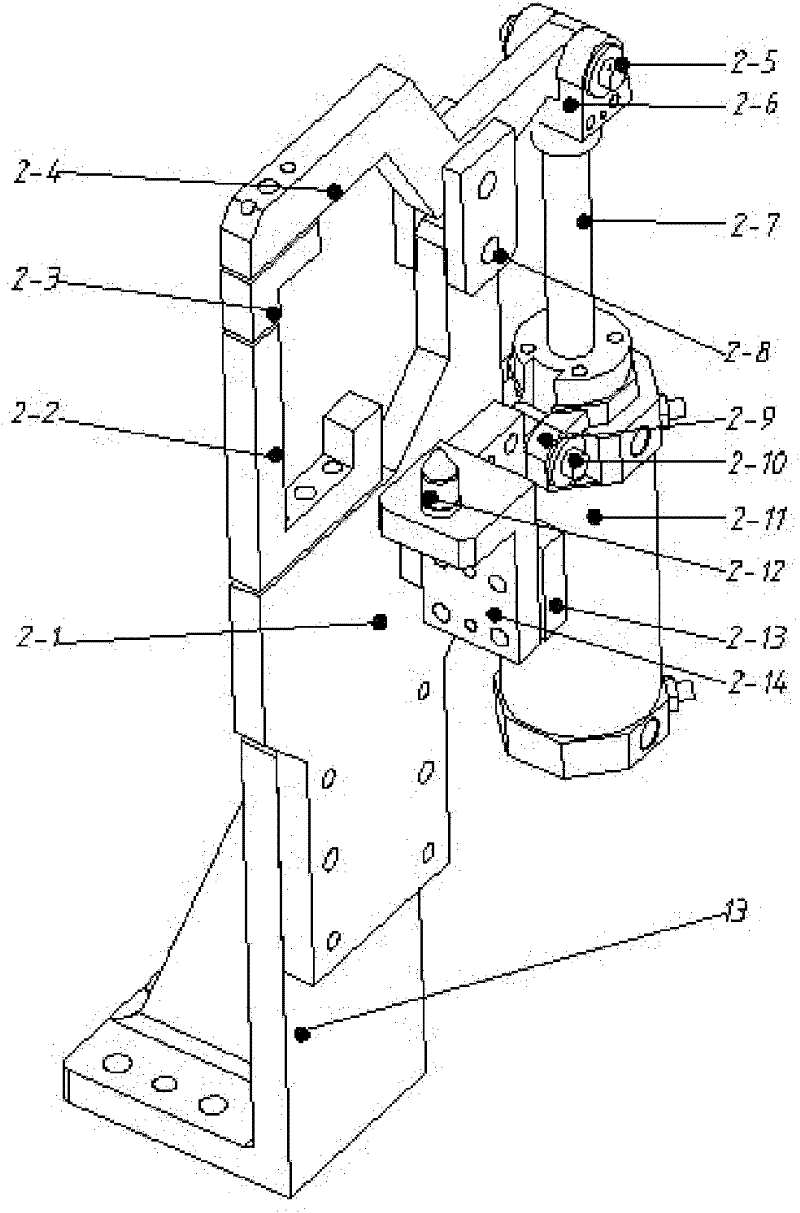

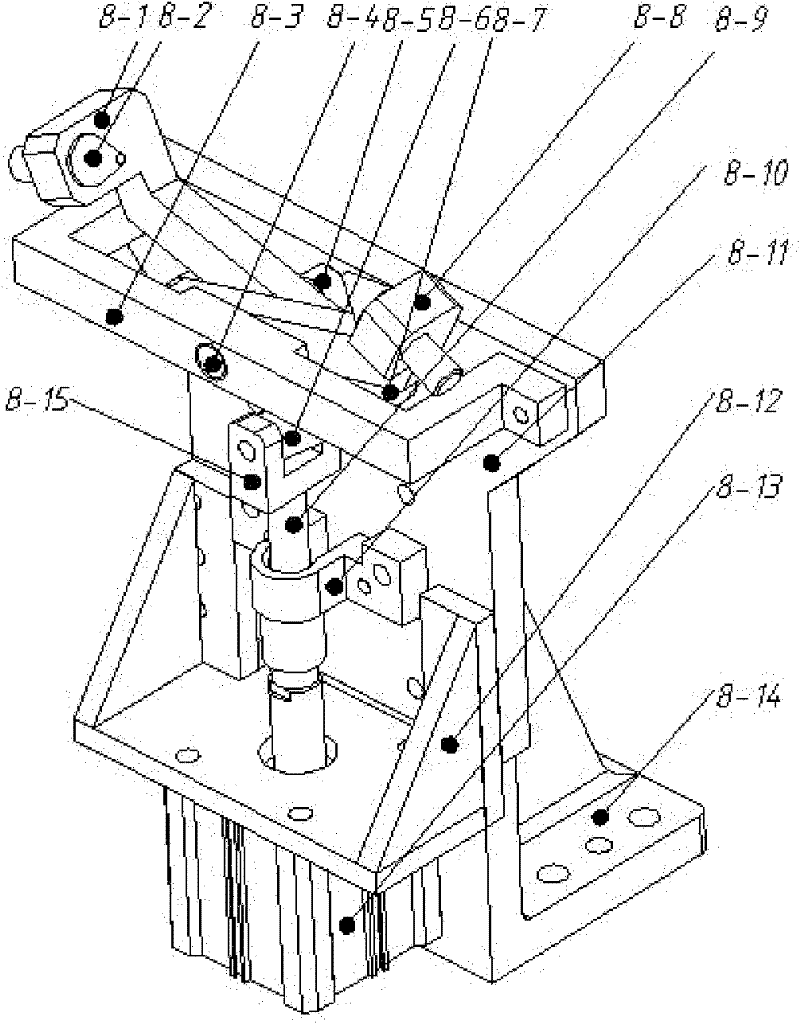

[0021] figure 1 It is a schematic diagram of the composition structure of the present invention, consisting of a working platform (1), 2 sets of tail rocker type positioning and locking devices (2), 2 sets of tail positioning devices (3), 2 sets of middle positioning devices (4), 2 sets of front Front positioning device (5), 2 sets of front rocker type positioning and locking devices (6), 2 sets of front positioning brackets (7), 2 sets of scissor type positioning and locking devices (8), 2 sets of dynamic positioning and locking Device (9), support body (10), adjustable support base (11), 2 sets of middle positioning supports (12), 2 sets of tail positioning supports (13), two-position five-way valve (14), cylinder , air pump, travel switch, air connection valve and other parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com