Aqueous acrylic acid adhesive and preparation method thereof

A technology of acrylic glue and acrylic acid, applied in the chemical industry, can solve the problems of prolonged drying time of water-based acrylic film, unsatisfactory initial tack and final tack strength, low water resistance and temperature resistance of the film, and achieve initial tack and final tack The effect of ideal strength, easy control and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Water-based acrylic adhesive, its raw material proportioning by weight is as follows: 20 parts of acrylic acid, 10 parts of methyl acrylate, 15 parts of ethyl acrylate, 10 parts of 2-ethylhexyl acrylate, 15 parts of methyl methacrylate , 10 parts of butyl acrylate, 10 parts of dimethylol propionic acid, 5 parts of triethylamine, 3 parts of silane coupling agent, 10 parts of OP-10, 5 parts of ethyl mercaptan, 5 parts of water-based tackifying rosin resin, 5 parts of water-based silicone oil, 300 parts of deionized water.

[0016] The preparation method of the above-mentioned water-based acrylic adhesive specifically includes the following steps.

[0017] Step 1, pre-emulsification treatment: add the above-mentioned parts by weight of acrylic acid, methyl acrylate, ethyl acrylate, 2-ethylhexyl acrylate, methyl methacrylate, butyl acrylate, dimethylol Propionic acid, triethylamine, silane coupling agent, half of OP-10, water-based silicone oil, deionized water, water-base...

Embodiment 2

[0020] Water-based acrylic adhesive, its raw materials are proportioned as follows in parts by weight: 18 parts of acrylic acid, 13 parts of methyl acrylate, 12 parts of ethyl acrylate, 11 parts of 2-ethylhexyl acrylate, and 10 parts of methyl methacrylate , 15 parts of butyl acrylate, 10 parts of dimethylol propionic acid, 5 parts of triethylamine, 5 parts of silane coupling agent, 10 parts of sodium lauryl sulfate, 3 parts of hydrocyanic acid, 5 parts of multi-carbon tackifying resin parts, 4 parts of water-based silicone oil, and 350 parts of deionized water.

Embodiment 3

[0022] Water-based acrylic adhesive, its raw materials are proportioned as follows in parts by weight: 20 parts of acrylic acid, 15 parts of methyl acrylate, 15 parts of ethyl acrylate, 13 parts of 2-ethylhexyl acrylate, and 11 parts of methyl methacrylate , 10 parts of butyl acrylate, 6 parts of dimethylol propionic acid, 10 parts of OP-10, 8 parts of triethylamine, 5 parts of silane coupling agent, 5 parts of hydrocyanic acid, 4 parts of water-based tackifying rosin resin, water-based 4 parts of silicone oil, 500 parts of deionized water.

[0023] 1. Performance testing.

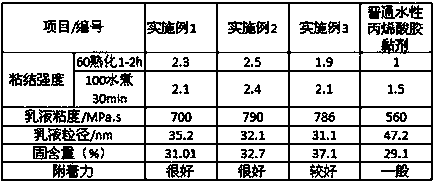

[0024] 1. The performance test results of the water-based acrylic adhesive prepared in Examples 1-3 are shown in Table 1.

[0025] Table 1 Rational indicators of waterborne polyurethane adhesives.

[0026]

[0027] It can be seen from Table 1 that, compared with the common water-based acrylic adhesive, the present invention has higher bond strength, emulsion viscosity, and smaller emulsion particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com