Production device for preparing distilled water by ion exchange technology

A technology of ion exchange and production equipment, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., which can solve the problems of increasing energy consumption, affecting heat transfer efficiency, reducing production Water volume and other issues to achieve the effect of ensuring water production, filtration effect, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

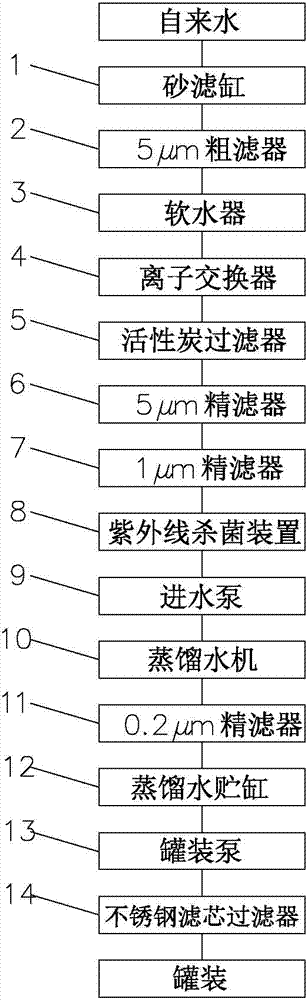

[0032] like figure 1 Shown, ion exchange technology prepares the production device of distilled water, and it comprises sand filter tank 1, activated carbon filter 5, ultraviolet sterilizing device 8, water inlet pump 9, distilled water machine 10 and distilled water storage tank 12, it also comprises softener 3, ion Exchanger 4, 5 μm fine filter 6 and 1 μm fine filter 7, sand filter cylinder 1, water softener 3, ion exchanger 4, activated carbon filter 5, 5 μm fine filter 6, 1 μm fine filter 7, ultraviolet sterilizing device 8, water inlet pump 9. The distilled water machine 10 and the distilled water storage tank 12 are connected successively; the regenerant used by the ion exchanger 4 is 30% hydrochloric acid and 99% flake solid sodium hydroxide diluted with water to a 30% regenerant.

[0033] This embodiment also includes a 5 μm coarse filter 2, a 0.2 μm fine filter 11, a filling pump 13 and a stainless steel element filter 14, the 5 μm coarse filter 2 is connected between...

Embodiment 2

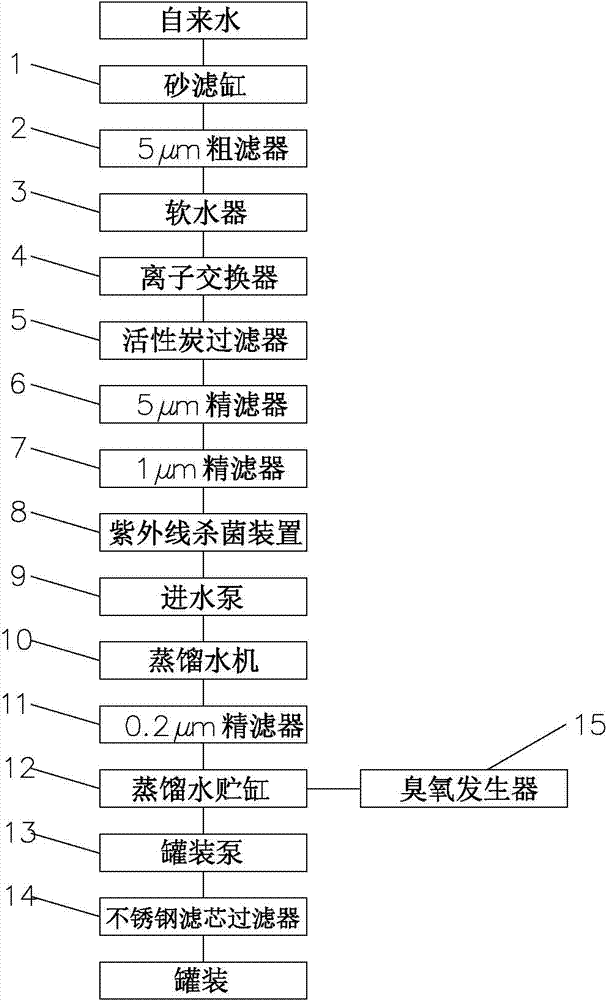

[0048] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the production device for preparing distilled water by the ion exchange technology described in this embodiment also includes an ozone generator 15 , and the ozone generator 15 is connected to the distilled water storage tank 12 .

[0049] Wherein, the ozone concentration added by the ozone generator 15 is above 0.6 mg / L. Ozone sterilizes distilled water, and at the same time has decolorization, deodorization, removal of iron, manganese, oxidative decomposition products and coagulation aid. It is necessary to detect the index of distilled water in the distilled water storage tank 12 once per hour, requiring O 3 Concentration ≥ 0.6mg / L, conductivity ≤ 10 uS / cm, pH value 5.0-7.0, turbidity ≤ 1NTU and no visible matter can be detected. Then it is delivered to the distilled water bottle by filling pump 13 for filling.

[0050] Features that are not explained in this embodiment are ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com