Negative ion soybean formaldehyde-free adhesive

A formaldehyde-free adhesive, soybean adhesive technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of not being suitable for large-scale industrial production, and achieve good economic value and social value, mechanical strength improvement, and the effect of avoiding formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

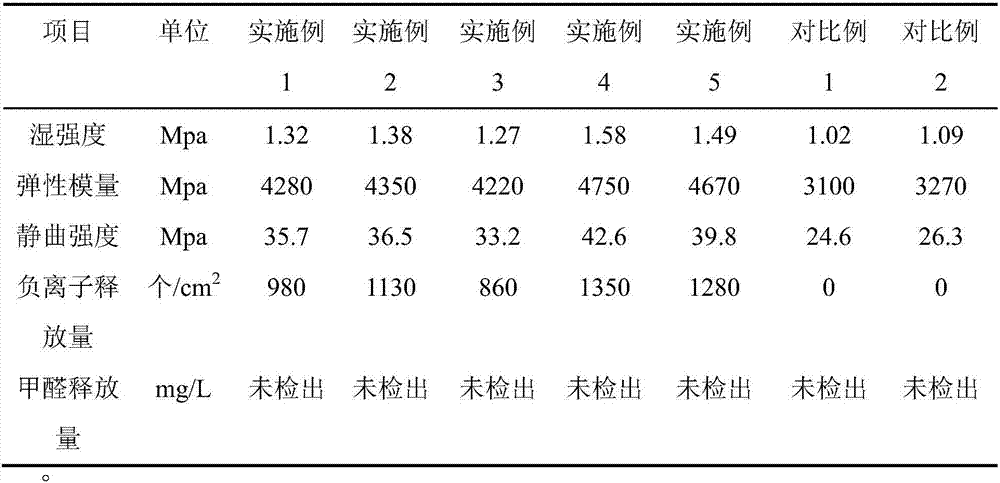

Examples

Embodiment 1

[0026] Add 100 parts by weight of water and 0.7 parts by weight of sodium hydroxide into a 1000ml beaker to form a sodium hydroxide solution, then add 60 parts by weight of silane coupling agent KH570, and finally add 2.4 parts by weight of tourmaline powder , and stirred for 10 min to obtain a mixed solution. Add 80 parts by weight of defatted soybean protein powder to the mixed liquid, stir for 30 minutes, mix and disperse evenly, and obtain an anionic soybean formaldehyde-free adhesive.

[0027] The prepared negative ion soybean glue is used for the bonding of five-layer eucalyptus boards, and the amount of glue on one side is 180-240g / m 2 After gluing, quickly cold press at 1.2Mpa for 20min, and then hot press at 130°C and 1.0Mpa for 20min. After forming, cool and put it aside, saw the board into the corresponding size, and test the bonding strength, elastic modulus, and negative ions. Determination of release, etc.

Embodiment 2

[0029] Add 100 parts by weight of water and 4.0 parts by weight of urea in a 1000ml beaker to form a urea solution, then add 60 parts by weight of ethylene glycol diglycidyl ether to the urea solution, and finally add 2.0 parts by weight of tourmaline powder and 0.4 parts by weight of kielite powder, stirred for 15 minutes to obtain a mixed solution. Add 65 parts by weight of soybean defatted soybean flour to the mixed liquid, stir for 25 minutes, mix and disperse evenly, and obtain an anionic soybean formaldehyde-free adhesive.

[0030] The prepared negative ion soybean glue was used for the bonding of five-layer eucalyptus boards. Process is identical with embodiment 1.

Embodiment 3

[0032] In the 1000ml beaker, add the water of 100 parts by weight and the sodium lauryl sulfonate of 0.1 parts by weight, be configured into solution, then add the waterborne epoxy resin of 60 parts by weight wherein, at last, add the seagull stone powder of 2.0 parts by weight, Stir for 12 min to obtain a mixed solution. Add 50 parts by weight of defatted soybean protein powder to the mixture, stir for 35 minutes, mix and disperse evenly, and obtain an anionic soybean formaldehyde-free adhesive.

[0033] The prepared negative ion soybean glue was used for the bonding of five-layer eucalyptus boards. Process is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com