Non-substrate easy-to-pull removable adhesive tape as well as preparation and use method thereof

A technology without base material and adhesive tape, which is applied in the direction of adhesives, film/sheet adhesives, rosin adhesives, etc. To adjust the limited space and other issues, to achieve the effect of improving initial adhesion and peel strength, high tensile elongation, and convenient after-sales maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

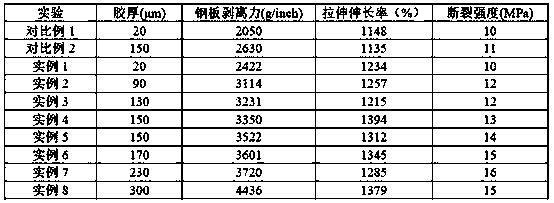

example 1

[0033] The rubber-type glue used to prepare the easy-to-pull removable tape contains the following raw materials in parts by weight: thermoplastic rubber (the block ratio of styrene segment (PS) / isoprene segment (PI) is about 30 / 70, such as SIS1209) 80 parts, tackifying resin (rosin ester: softening point is 103 ℃, acid value 12, such as GB100) 70 parts, toluene 200 parts, liquid rosin ester (softening point is 12 ℃, acid value 9, such as Arizona chemical SYLVATAC ™ RE 12) 15 parts, 3 parts of color paste, 0.4 parts of leveling agent; dissolve rosin ester with toluene first, then add thermoplastic rubber, liquid rosin ester, color paste, leveling agent in turn, and get glue after stirring evenly; adjust Coating thickness, apply the glue on the release paper or release film, dry, and stick it with release paper or release film to obtain a substrate-free easy-to-pull removable tape with a thickness of 20 μm.

[0034] No base material, easy-pull removable tape, just peel off the ...

example 2

[0036]The rubber-type glue used to prepare the easy-to-pull removable tape contains the following raw materials in parts by weight: thermoplastic rubber (the block ratio of styrene segment (PS) / isoprene segment (PI) is about 30 / 70, such as SIS1209) 100 parts, tackifying resin (rosin ester: softening point is 105 °C, acid value 21, such as Arakawa Chemical GH100) 120 parts, toluene 250 parts, liquid rosin ester (softening point is 12 °C, acid value is 9, such as Arizona Chemical SYLVATAC™ RE 12) 20 parts, 6 parts of color paste, 0.55 parts of leveling agent; first dissolve rosin ester with toluene, then add thermoplastic rubber, liquid rosin ester, color paste, and leveling agent in sequence, and mix well to obtain glue ;Adjust the coating thickness, apply the glue on the release paper or release film, dry it, and stick it with release paper or release film to obtain a substrate-free easy-to-pull removable tape with a thickness of 90 μm .

[0037] No base material, easy-pull r...

example 3

[0039] The rubber-type glue used to prepare the easy-to-pull removable tape contains the following raw materials in parts by weight: thermoplastic rubber (the block ratio of styrene segment (PS) / isoprene segment (PI) is about 20 / 80, such as Yueyang Petrochemical SIS1188) 100 parts, tackifying resin (rosin ester: softening point is 100 ℃, acid value 12, such as GB100 of Wuzhou Arakawa Chemical) 120 parts, toluene 150 parts, liquid rosin ester (softening point is 25 ℃, acid value 15, such as SYLVATAC™ RE 25) 15 parts, 5 parts of color paste, 0.45 parts of leveling agent; first dissolve rosin ester with toluene, then add thermoplastic rubber, liquid rosin ester, color paste, and leveling agent in sequence, and stir evenly Finally, the glue is obtained; adjust the coating thickness, apply the glue on the release paper or film, dry, and stick it with the release paper or film to obtain a substrate-free roll-up with a thickness of 130 μm Remove the tape.

[0040] No base material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com