Bright silver reflective fabric complex adhesive and preparation method thereof

A technology of reflective cloth and composite adhesive, applied in the direction of adhesive, adhesive type, adhesive additive, etc., can solve the problems of affecting the use effect of bright silver reflective cloth, poor corrosion resistance, low bonding strength, etc., and achieve improved initial adhesion Excellent performance in sex and bonding strength, good corrosion resistance, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

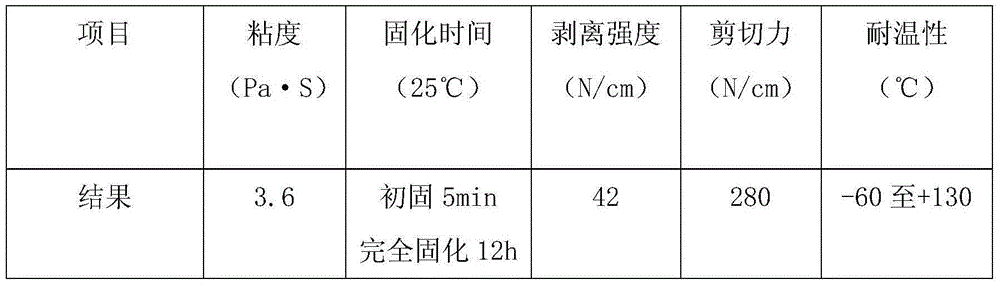

Image

Examples

Embodiment Construction

[0010] A bright silver reflective cloth composite glue, made of the following raw materials by weight (kg): acrylic resin 25, diphenylmethane diisocyanate 3, tetraisopropyl titanate 2, polymethylphenylsiloxane 12, poly α-methyl styrene resin 8, ethyl acetate 15, modified aluminum silver powder 0.5, pearl powder 0.3, polymerized ferrophosphorus powder 0.7, aluminum dihydrogen tripolyphosphate 1.5, nanometer titanium carbide 2.5.

[0011] The preparation method of the modified aluminum silver powder is as follows: a, in parts by mass, get 100 parts of micron aluminum silver powder and add in the ball mill, then add 450 parts of distilled water, 8 parts of sodium hexametaphosphate, 6 parts of cocoyl glutamic acid Acid triethanolamine salt, 4 parts of sodium polystyrene sulfonate, 1.5 parts of sodium lauryl sulfate, ball milled at 60r / min for 12 hours, filtered after ball milling, dried in vacuum at 75°C, and then added 6 parts of diglycidyl terephthalate Esters, 4 parts of maleic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com