Self-crosslinking vinyl acetate-acrylic emulsion modified with waterborne neoprene latex and cured at room temperature and preparation method of vinyl acetate-acrylic emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

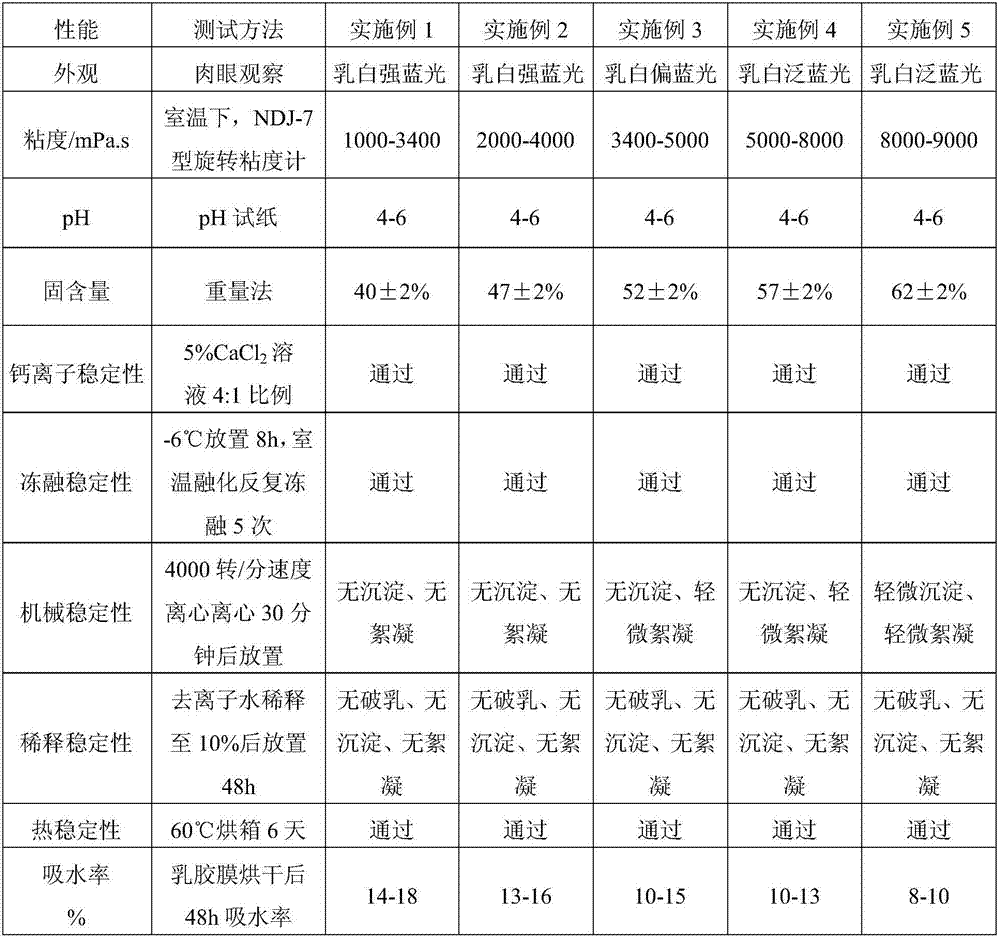

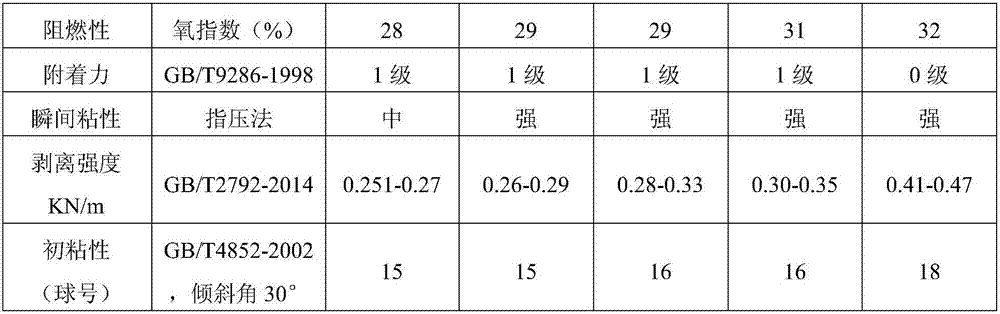

Examples

Embodiment 1

[0056] A kind of vinegar-acrylic emulsion modified by self-crosslinking water-based neoprene latex at room temperature is composed of the following components, specifically comprising: 55.93kg of deionized water; 12.66kg of water-based neoprene latex; 8.12kg of butyl acrylate; 12.12kg kg of vinyl acetate; 12.12kg of isooctyl acrylate; 1.40kg of methacrylic acid; 0.30kg of polyvinyl alcohol; 1.55kg of nonylphenol ethoxylates; 0.78Kg of sodium lauryl sulfate; 0.07 kg of sodium bicarbonate; 0.14 kg of ammonium persulfate; 0.42 kg of diacetone acrylamide; 0.21 kg of succinic acid dihydrazide; 0.025 kg of tert-butyl hydroperoxide;

[0057] Its preparation method comprises the following steps:

[0058] 1. 12.66kg of water-based neoprene latex, 8.12kg of butyl acrylate, 12.12kg of vinyl acetate, 1.05kg of methacrylic acid, 0.42kg of diacetone acrylamide, 1.33kg of nonylphenol polyoxyethylene ether The sodium lauryl sulfate of 0.66kg and the isooctyl acrylate of 12.12kg join the deio...

Embodiment 2

[0066] A kind of vinegar-acrylic emulsion modified by self-crosslinking water-based neoprene latex at room temperature is composed of the following components, specifically comprising: 51.8kg of deionized water; 13.46kg of water-based neoprene latex; 10.02kg of butyl acrylate; 14.02 kg kg of vinyl acetate; 10.43 kg of isooctyl acrylate; 1.43 kg of methacrylic acid; 0.23 kg of polyvinyl alcohol; 1.78 kg of nonylphenol ethoxylates; 0.89 kg of sodium lauryl sulfate; 0.076 kg of sodium bicarbonate; 0.15 kg of sodium persulfate; 0.48 kg of diacetone acrylamide; 0.24 kg of succinic acid dihydrazide; 0.028 kg of tert-butyl hydroperoxide;

[0067] Its preparation method comprises the following steps:

[0068] 1. 13.46kg of water-based neoprene latex, 10.02kg of butyl acrylate, 14.02kg of vinyl acetate, 1.07kg of methacrylic acid, 0.48kg of diacetone acrylamide, 1.53kg of nonylphenol polyoxyethylene ether , 0.76kg of sodium lauryl sulfate and 10.43kg of isooctyl acrylate are added to ...

Embodiment 3

[0076] A kind of vinegar-acrylic emulsion modified by self-crosslinking water-based neoprene latex at room temperature is composed of the following components, specifically comprising: 47.68kg of deionized water; 14.27kg of water-based neoprene latex; 11.92kg of butyl acrylate; 15.92kg kg of vinyl acetate; 10.99kg of isooctyl acrylate; 1.45kg of acrylamide; 0.25kg of polyvinyl alcohol; 2.01kg of nonylphenol ethoxylates, 1.005kg of sodium lauryl sulfate; 0.0815kg 0.17kg of ammonium persulfate; 0.53kg of diacetone acrylamide; 0.265kg of adipic dihydrazide; 0.03kg of tert-butyl hydroperoxide;

[0077] Its preparation method comprises the following steps:

[0078] 1. 14.27kg of water-based neoprene latex, 11.92kg of butyl acrylate, 15.92kg of vinyl acetate, 1.0875kg of acrylamide, 0.53kg of diacetone acrylamide, 1.72kg of nonylphenol polyoxyethylene ether, Add 0.86kg of sodium lauryl sulfate and 10.99kg of isooctyl acrylate into 31.00kg of deionized water, and stir and emulsify t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com