Polyether ester multi-block copolymerized dihydric alcohol, synthetic method and application of reactive hot melt adhesive

A technology of polyether diol and polyether polyol, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problem of easy blockage of rectification channel and difficulty in obtaining polyether ester copolymer di Alcohol and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

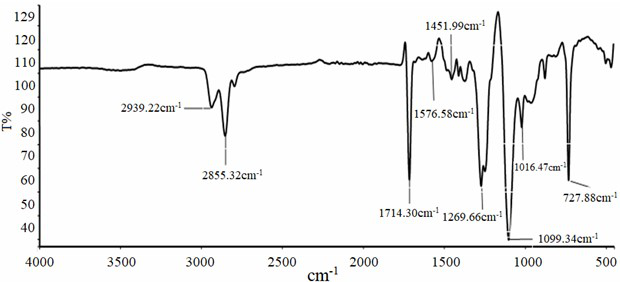

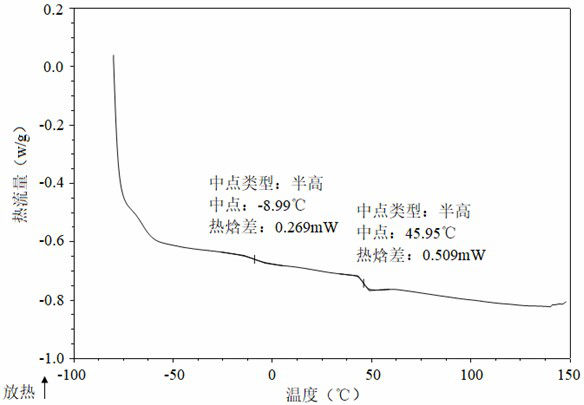

Image

Examples

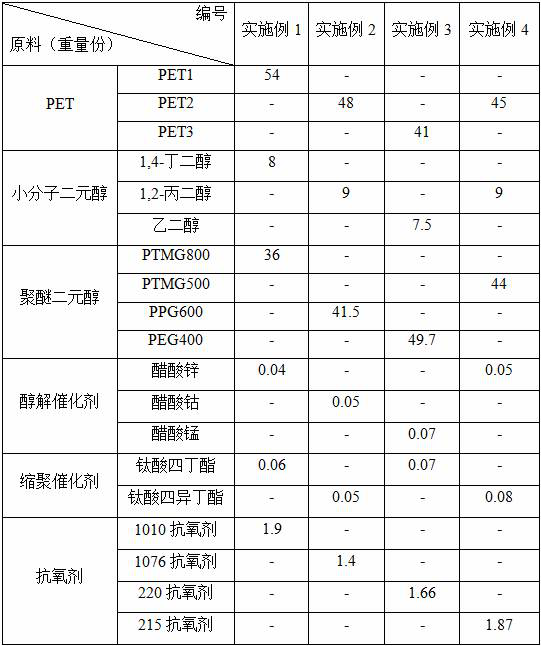

Embodiment 1

[0066] According to each raw material and parts by weight described in Example 1 in Table 1, polyethylene terephthalate, small molecule glycol, polyether glycol and alcoholysis catalyst are added in the reactor earlier, and protected under a nitrogen atmosphere After heating up to 190°C for alcoholysis reaction for 1.5h, then add polycondensation catalyst and antioxidant, after heating up to 240°C, first depressurize to -0.04MPa vacuum, after polycondensation for 1h, then depressurize to - Under the vacuum degree of 0.095MPa, carry out the polycondensation reaction for 3 hours, distill out the small molecule diol at the end of the polycondensation product, and cool to obtain the PET / PTMG type polyether ester multi-block copolymerized diol, which is denoted as PET / PTMG1.

[0067] As determined by GPC, the molecular weight of the PET / PTMG type polyether ester multi-block copolymerized diol obtained in the embodiment of the present invention is 4800, and the degree of dispersion i...

Embodiment 2

[0072] According to each raw material and parts by weight described in Example 2 in Table 1, polyethylene terephthalate, small molecule dibasic alcohol, polyether dibasic alcohol and alcoholysis catalyst are added in the reactor earlier, under nitrogen atmosphere protection After the temperature is raised to 185°C for alcoholysis reaction for 2 hours, then polycondensation catalyst and antioxidant are added, after the temperature is raised to 235°C, the pressure is reduced to -0.03MPa vacuum, and after the polycondensation reaction for 1.5h, the pressure is reduced to - Under the vacuum degree of 0.098MPa, carry out the polycondensation reaction for 2.5h, distill out the small molecule diol at the terminal group of the polycondensation product, and cool to obtain PET / PPG type polyether ester multi-block copolymerized diol, denoted as PET / PPG2.

[0073] As determined by GPC, the molecular weight of the PET / PPG type polyether ester multi-block copolymerized glycol obtained in the...

Embodiment 3

[0078] According to each raw material and parts by weight described in Example 3 in Table 1, polyethylene terephthalate, small molecule glycol, polyether glycol and alcoholysis catalyst are added in the reactor earlier, and protected under a nitrogen atmosphere After heating up to 195°C for alcoholysis reaction for 1.5h, then add polycondensation catalyst and antioxidant, after warming up to 245°C, first depressurize to -0.05MPa vacuum degree, after polycondensation reaction for 1h, then depressurize to - Under the vacuum degree of 0.098MPa, carry out the polycondensation reaction for 2.5h, distill out the polycondensation product terminal small molecular diol, cool to obtain PET / PEG type polyether ester multi-block copolymerized diol, denoted as PET / PEG3.

[0079] As determined by GPC, the molecular weight of the PET / PEG polyether ester multi-block copolymerized glycol obtained in the embodiment of the present invention is 3500, and the degree of dispersion is 2.3.

[0080] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com