Alkyl phenolic resin rubber tackifier and preparation method

A technology of alkyl phenolic resin and tackifier, which is used in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc. There is no significant increase in the resultant force, and the effect of good lasting viscosity, improved adhesion, and prevention of bead voiding and blasting can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 82.4g (0.4mol) of p-tert-octylphenol and 100g methanol to a 500ml reaction flask, stir and slowly heat up to 65°C, respectively, through a dropping funnel and a screw feeder, and uniformly dropwise add 15% hydrogen peroxide 106.7 g (0.4 mol) of sodium methanol solution and 86.2 g (0.4 mol) of 2-chloromethylthiobenzothiazole were added, and the pH value was kept in the range of 9-11, and the addition time was about 120 minutes. Continue to stir and keep warm for 60 minutes after the addition is complete. Then the temperature was raised and methanol was distilled off. When the distillation temperature reached 110°C, it was kept for half an hour. Then it is lowered to room temperature, washed with water, filtered and dried, and it is the etherate monomer A of the present invention.

Embodiment 2

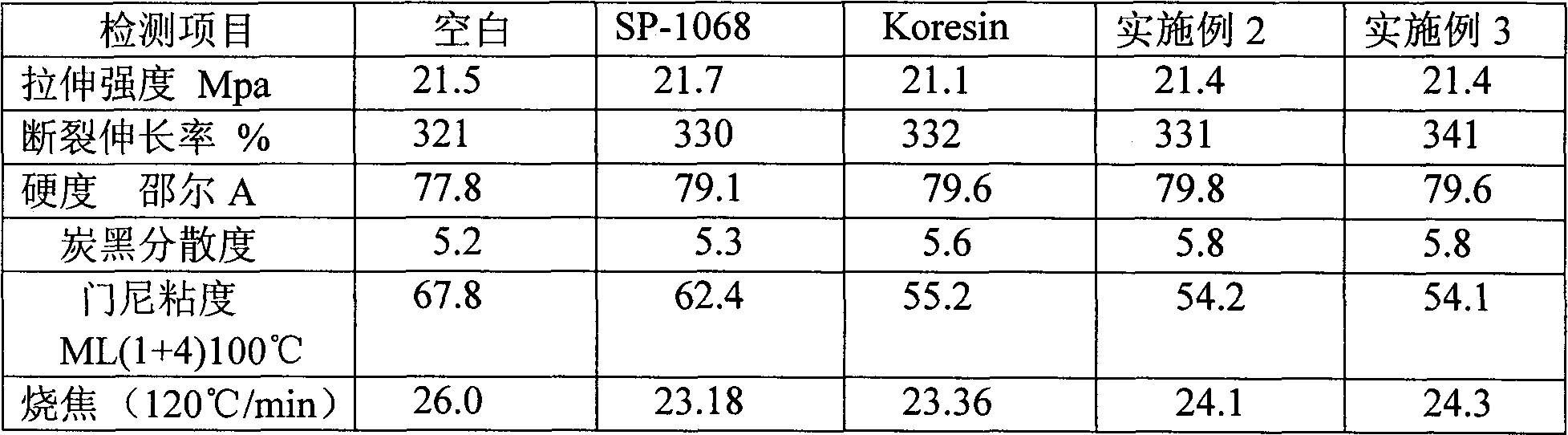

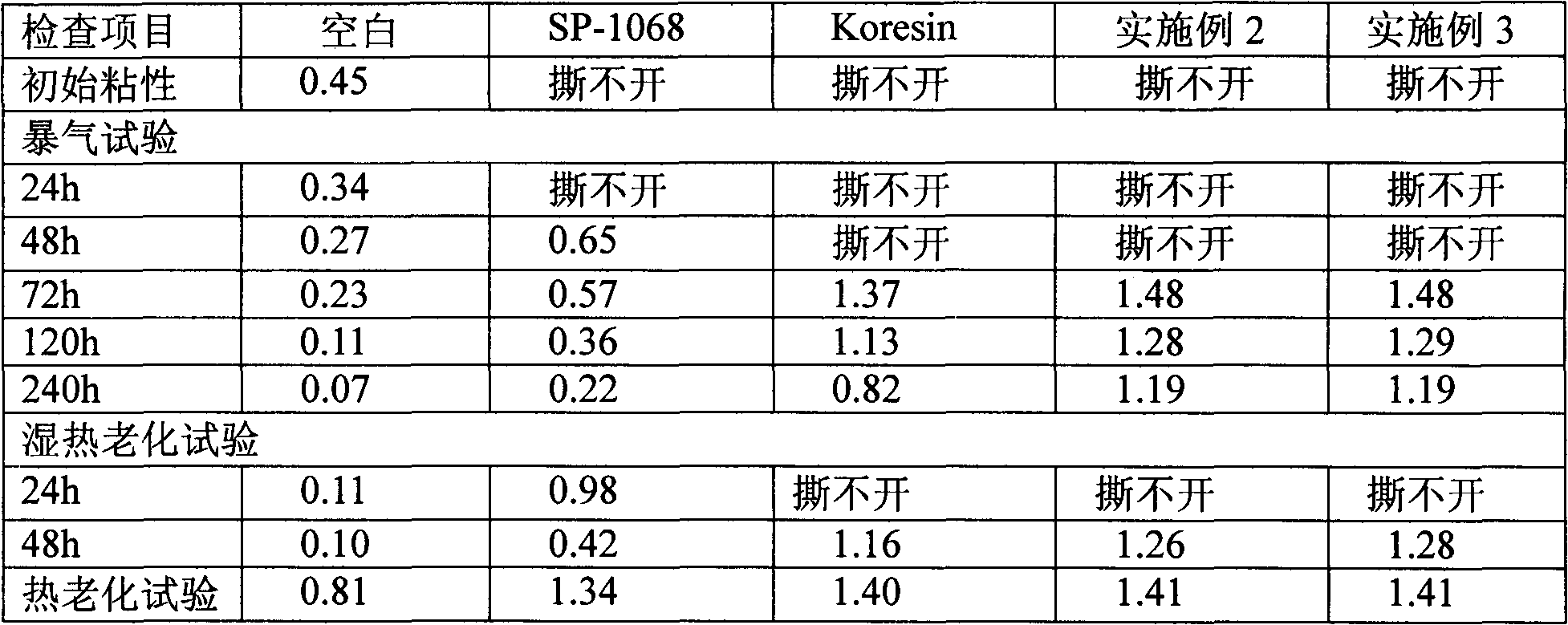

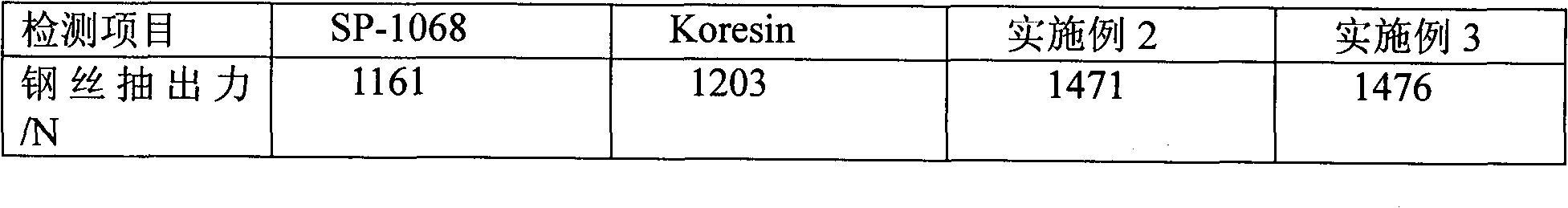

[0027] Into a 1000 ml reaction flask, 82.4 g (0.4 mol) of p-tert-octylphenol, 38.5 g (0.1 mol) of etherified monomer A, 40 ml of toluene, and 1 g of 36% hydrochloric acid were added. Turn on the condensed water in the reflux pipe, stir and heat up, and the reflux phenomenon occurs when the material rises to about 85 °C. Keeping the reflux state and continuous stirring, 34 g (0.42 mol) of 37% formaldehyde aqueous solution was added dropwise from the addition funnel, and the dropwise addition time was about 30 minutes. After the dropwise addition of formaldehyde, continue stirring and refluxing for 180 minutes, and then neutralize the material to neutrality with 20% aqueous sodium hydroxide solution. 90 ml of toluene was added, stirred for 20 minutes, left to stand for layers, and the aqueous phase was separated. Then 100 ml of water was added, the temperature was kept at 70° C. and stirred for 20 minutes. Continue to stir and heat up to steam out toluene and residual moisture...

Embodiment 3

[0029] Into a 1000 ml reaction flask, 72.1 g (0.35 mol) of p-tert-octylphenol, 57.8 g (0.15 mol) of etherified monomer A, 40 ml of toluene, and 1 g of 36% hydrochloric acid were added. Turn on the reflux condensed water, stir to heat up, and the reflux phenomenon occurs when the material rises to about 85 °C. Keeping reflux and stirring, 34 g (0.42 mol) of a 37% aqueous formaldehyde solution was added dropwise from the addition funnel for about 30 minutes. After the dropwise addition of formaldehyde, the mixture was continuously stirred and refluxed for 180 minutes, and then neutralized to neutrality with 20% aqueous sodium hydroxide solution. 90 ml of toluene was added, stirred for 20 minutes, left to stand for layers, and the aqueous phase was separated. Then 100 ml of water was added, the temperature was kept at 70° C., stirred for 20 minutes, left to stand for stratification, and the water phase was separated out again. Continue to stir and heat up to steam out toluene a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com