Pressure-sensitive adhesive for intelligent touch screen protective film and preparation method thereof

A technology of protective film and touch screen, applied in the field of pressure-sensitive adhesive, can solve the problems of destroying the adhered product, increasing the adhesion of the protective film, and poor exhaust, achieving good adhesion, excellent stability, The effect of low peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

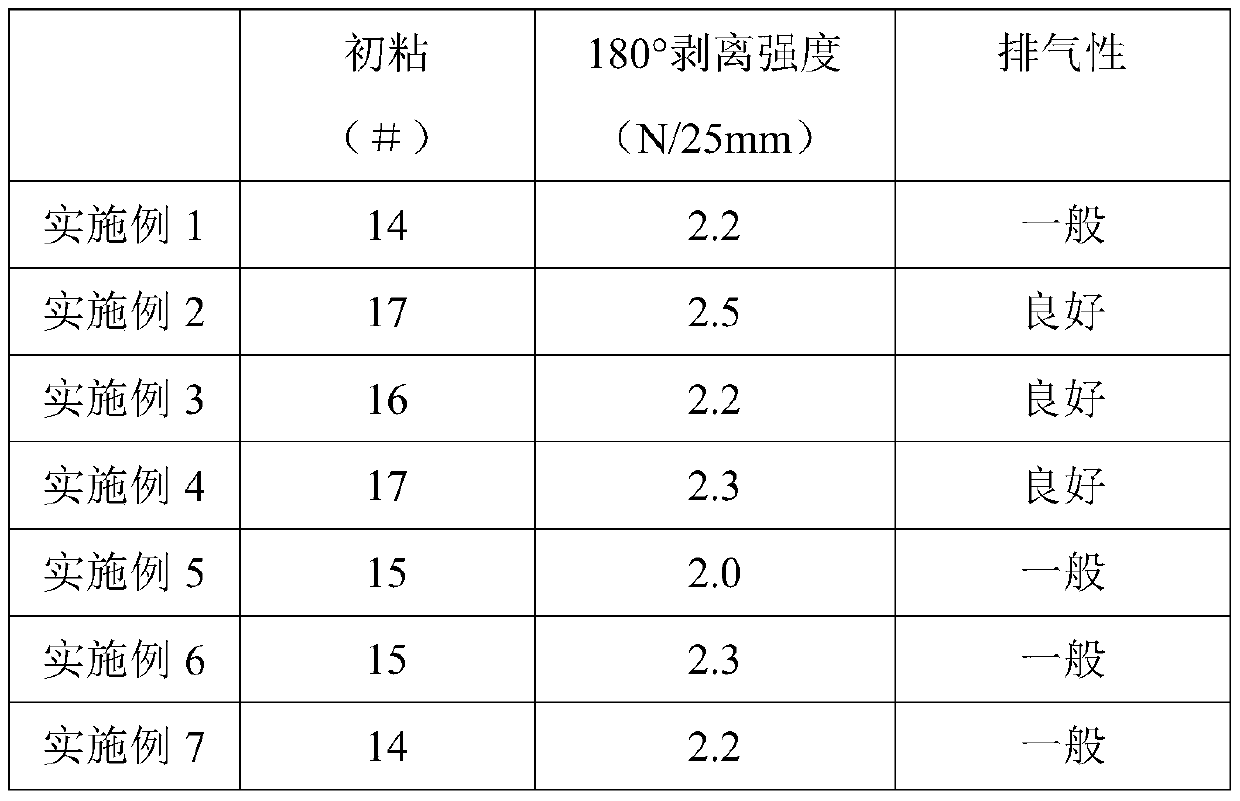

Examples

preparation example Construction

[0052] The second aspect of the present invention is to provide the above-mentioned preparation method of the pressure-sensitive adhesive used for the protective film of the smart touch screen, comprising the following steps:

[0053] A. Weigh soft monomers, functional monomers, and initiators with two-thirds of the feeding amount in proportion, add them to the high-level tank, and stir evenly to obtain the mixed material;

[0054] B, take by weighing the solvent of 40-60% of feeding amount, put into reaction kettle and heat up to reflux state;

[0055] C, quickly drop one-third of the mixed material into the reactor, and keep the reflux reaction for 1-1.5h;

[0056] D. Add the rest of the mixed material dropwise at a constant speed in the reactor, control it in 3-3.5h, and then reflux and keep warm for 0.5-1.5h after dropping;

[0057] E. Add 1 / 6th initiator and 5-15% solvent mixed solution, and keep it under reflux for 0.5-1.5h;

[0058] F, adding 1 / 6th of the initiator an...

Embodiment 1

[0067] The pressure-sensitive adhesive used for the protective film of the intelligent touch screen is prepared from the following raw materials in mass percentage: 97% of polyacrylate resin and 3% of curing agent.

[0068] The isocyanate curing agent is hexamethylene polyisocyanate (Bayer N3390, Germany).

[0069] The polyacrylate resin includes the following raw materials in parts by weight: 24 parts of soft monomers, 6 parts of functional monomers, 70 parts of solvents, and 0.25 parts of initiators.

[0070] The soft monomer is composed of butyl acrylate and isooctyl acrylate in a mass ratio of 1:1.5.

[0071] The functional monomer is composed of acrylic acid and hydroxyethyl acrylate in a mass ratio of 1:1.

[0072] The solvent is ethyl acetate.

[0073] The initiator is dibenzoyl peroxide.

[0074] The above-mentioned preparation method of the pressure-sensitive adhesive used for the protective film of the intelligent touch screen comprises the following steps:

[00...

Embodiment 2

[0087] The pressure-sensitive adhesive used for the protective film of the intelligent touch screen is prepared from the following raw materials in mass percentage: 97% of polyacrylate resin and 3% of curing agent.

[0088] The isocyanate curing agent is hexamethylene polyisocyanate (Bayer N3390, Germany).

[0089] The polyacrylate resin includes the following raw materials in parts by weight: 24 parts of soft monomers, 6 parts of functional monomers, 70 parts of solvents, and 0.25 parts of initiators.

[0090] The soft monomer is composed of butyl acrylate and isooctyl acrylate in a mass ratio of 1:1.5.

[0091] The functional monomer is composed of acrylic acid, hydroxyethyl acrylate, and 3-(methacryloyloxy)propyltrimethoxysilane in a mass ratio of 1:1:0.6.

[0092] The solvent is ethyl acetate.

[0093] The initiator is dibenzoyl peroxide.

[0094] The above-mentioned preparation method of the pressure-sensitive adhesive used for the protective film of the intelligent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com