Novel adhesive sticker with viscous force reduced after UV illumination and preparation method thereof

A new type of sticky technology, applied in the direction of adhesive types, ester copolymer adhesives, non-polymer adhesive additives, etc., which can solve the problems of high defect rate, high initial viscosity, and easy downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

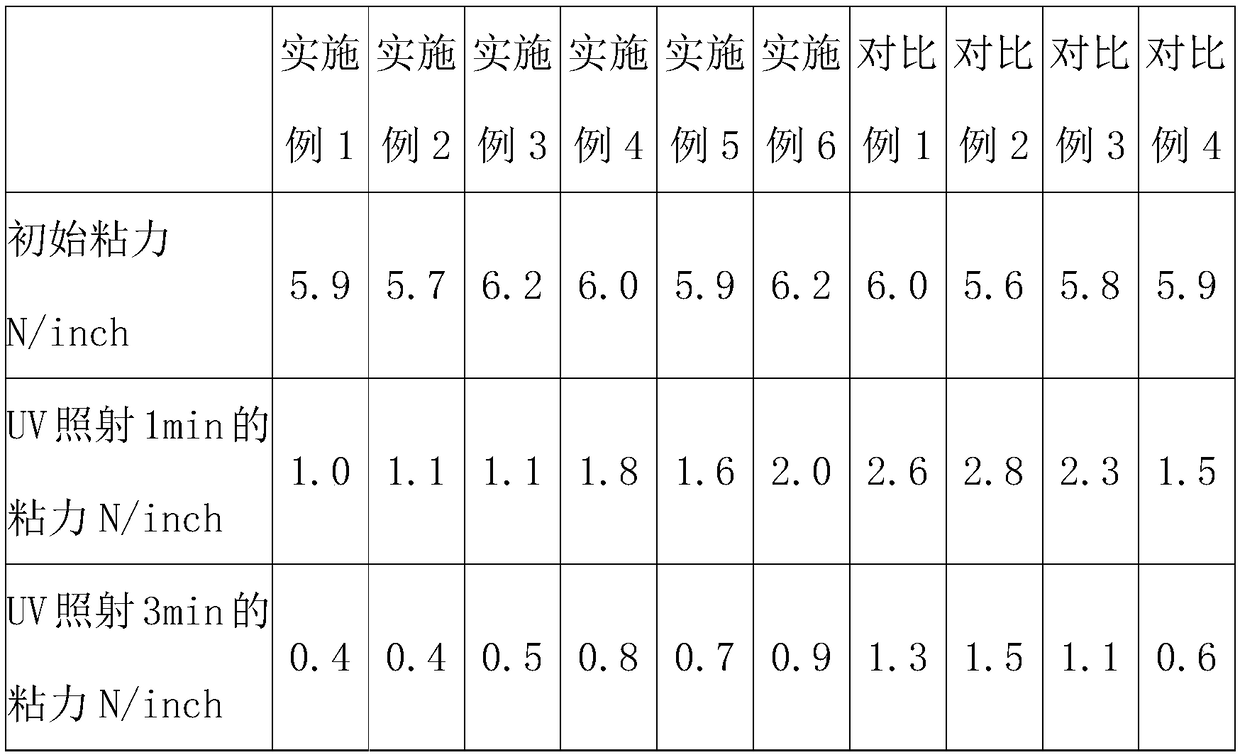

Examples

Embodiment 1

[0020] A new type of self-adhesive for reducing viscosity by UV light, which is characterized in that it includes a release backing paper and an outer adhesive layer, wherein the outer adhesive layer includes an acrylic pressure-sensitive adhesive with a molecular weight of 500,000-600,000 and an ultraviolet light area of 250 -420nm free radical photoinitiator and isocyanate, the thickness of the outer adhesive layer is 18-25um; the mass ratio of the acrylic pressure sensitive adhesive, isocyanate and free radical photoinitiator is 100:2.2:16; the release backing paper 80g glassine backing paper with release liner was used for coating.

[0021] The outer adhesive layer also includes a triarylsulfonium salt photoinitiator I-160, and the mass ratio of the triarylsulfonium salt photoinitiator I-160 to the free radical photoinitiator is 1.2:5. The free radical photoinitiator is a hydrogen abstraction type photoinitiator BP. The outer adhesive layer also includes nano-lanthanum ...

Embodiment 2

[0024] A new type of self-adhesive for reducing viscosity by UV light, which is characterized in that it includes a release backing paper and an outer adhesive layer, wherein the outer adhesive layer includes an acrylic pressure-sensitive adhesive with a molecular weight of 500,000-600,000 and an ultraviolet light area of 250 -420nm free radical photoinitiator and isocyanate, the thickness of the outer adhesive layer is 18um; the mass ratio of the acrylic pressure sensitive adhesive, isocyanate and free radical photoinitiator is 100:1.5:20; the release backing paper uses 80 grams of glassine backing paper with release function for coating.

[0025] The outer adhesive layer also includes a triarylsulfonium salt photoinitiator I-160, and the mass ratio of the triarylsulfonium salt photoinitiator I-160 to the free radical photoinitiator is 1:5. The free radical photoinitiator is a hydrogen abstraction type photoinitiator BP. The outer adhesive layer also includes nano-lanthanu...

Embodiment 3

[0028] A new type of self-adhesive for reducing viscosity by UV light, which is characterized in that it includes a release backing paper and an outer adhesive layer, wherein the outer adhesive layer includes an acrylic pressure-sensitive adhesive with a molecular weight of 500,000-600,000 and an ultraviolet light area of 250 -420nm free radical photoinitiator and isocyanate, the thickness of the outer adhesive layer is 25um; the mass ratio of the acrylic pressure-sensitive adhesive, isocyanate and free radical photoinitiator is 100:3:12; the release backing paper uses a 80 grams of glassine backing paper with release function for coating.

[0029] The outer adhesive layer also includes a triarylsulfonium salt photoinitiator I-160, and the mass ratio of the triarylsulfonium salt photoinitiator I-160 to the free radical photoinitiator is 1.5:5. The free radical photoinitiator is a hydrogen abstraction type photoinitiator BP. The outer adhesive layer also includes nano-lantha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com