Automatic cutting and separating equipment for photovoltaic cells

A photovoltaic cell and separation equipment technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of mobile stage movement accuracy error, affecting laser cutting accuracy, poor cutting accuracy stability, etc., to reduce manpower cost and production cost, increase output and production efficiency, and enhance market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned and other purposes, features, and advantages of the present invention more clearly understood, a preferred embodiment is specifically cited below, together with the accompanying drawings, and described in detail as follows, but the present invention is not limited to specific The example.

[0028] The purpose of the present invention is to provide an automatic cutting and separating equipment for photovoltaic cells, which can replace the manual operation method used in the prior art, and simultaneously take into account high process efficiency, high yield and high yield.

[0029] An automatic cutting and separating device for photovoltaic cells in a preferred embodiment of the present invention includes the following description.

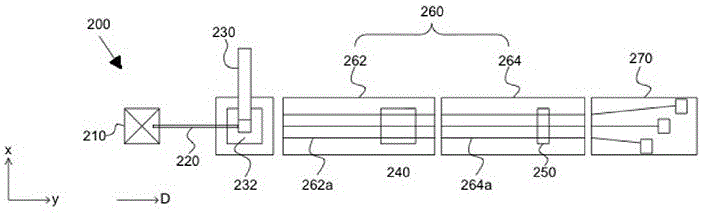

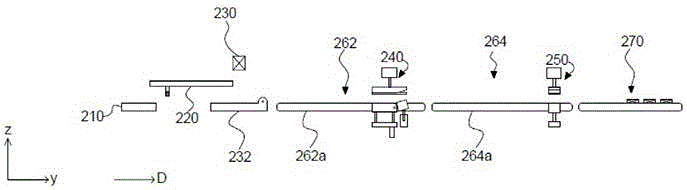

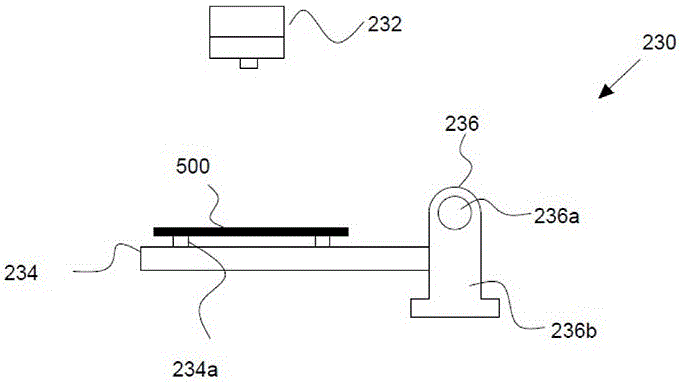

[0030] Please refer to figure 1 - Figure 6C , is a schematic diagram of an automatic cutting and separating equipment for photovoltaic cells according to an embodiment of the present invention. Please ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com