Linear regression model-based maintenance support object consumption prediction method

A linear regression model and prediction method technology, applied in the field of maintenance statistics, can solve the problems of unguaranteed accuracy, difficulty in popularization, and serious reliance on experts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] Specific implementation method: a method for predicting the consumption of maintenance support objects based on a linear regression model. This method is based on standard equipment comparison. This method includes:

[0034] Step 1: Basic equipment selection;

[0035] Step 2: Selection of basic equipment task items;

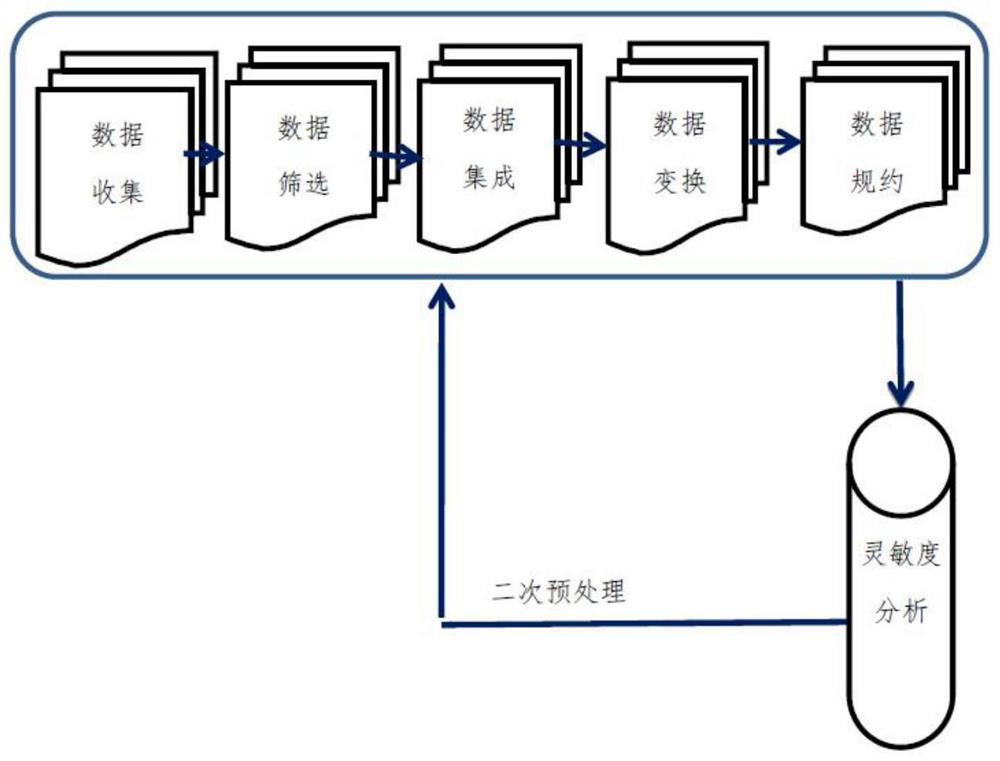

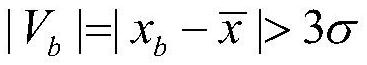

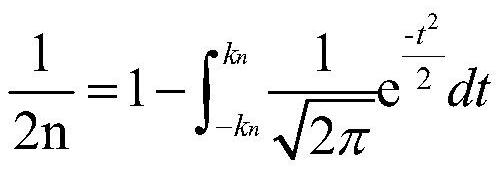

[0036] Step 3: Preprocessing of basic equipment task man-hour data;

[0037] Step 4: Collection of man-hour data for basic equipment tasks;

[0038] Step 5: Man-hour data processing of basic equipment task items;

[0039] Step 6: Specify the standard man-hours and man-hour quotas for single equipment repair.

[0040] The first step includes: selection of basic equipment, each major should select new equipment with a relatively comprehensive system composition and strong typicality as the basic equipment. Subsystems, sub-systems, equipment, combinations and other functional structural parts of basic equipment are typical and comparable, which is conveni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com