Flexible circuit board, and mechanism and method for connecting flexible circuit board and printed circuit board

A flexible circuit board and printed circuit board technology, which is applied in the structural connection of printed circuits, the formation of electrical connections of printed components, and the assembly of printed circuits with electrical components, can solve problems such as poor reliability and unreasonable connection structure between FPC and PCB. Achieve good reliability and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

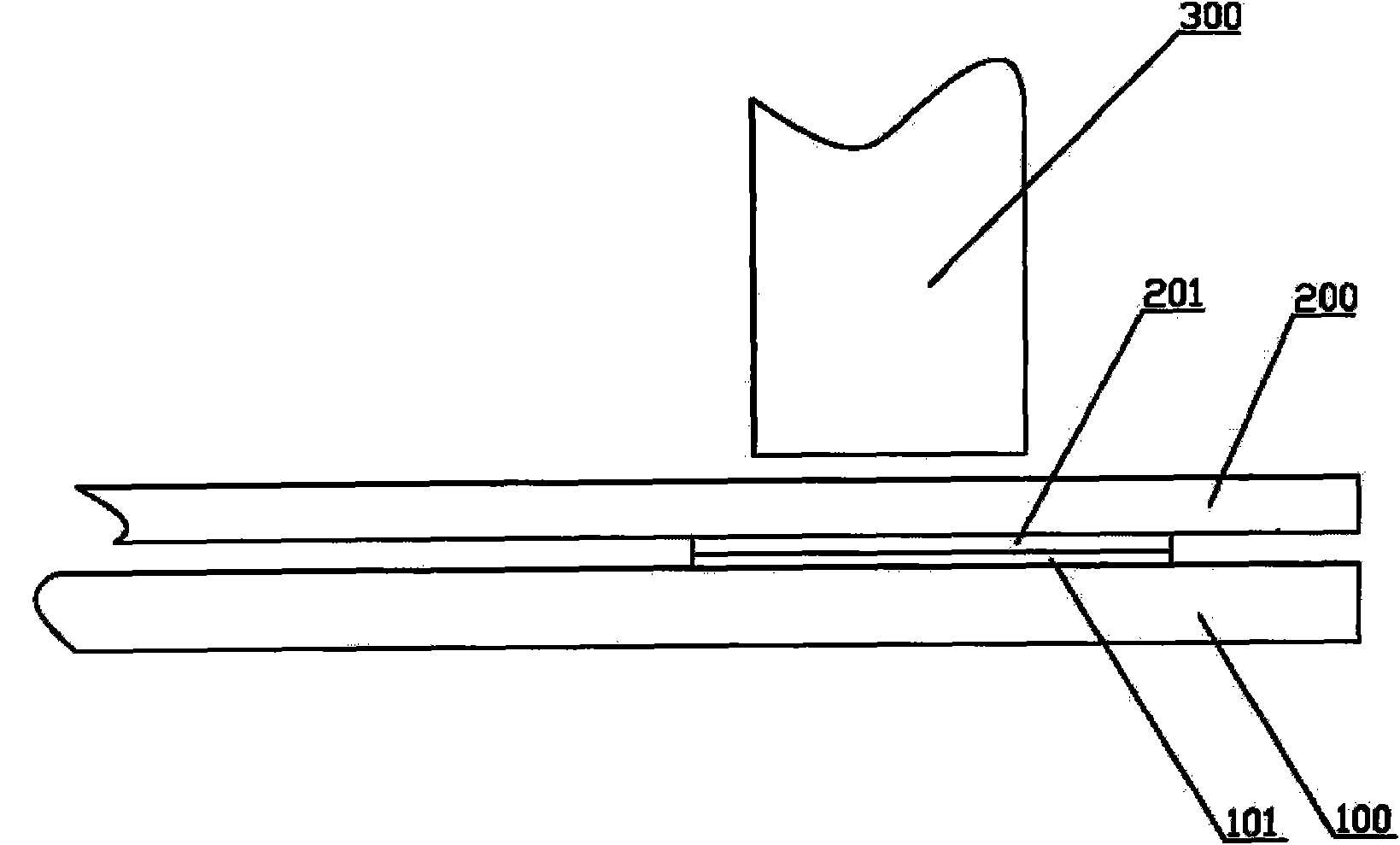

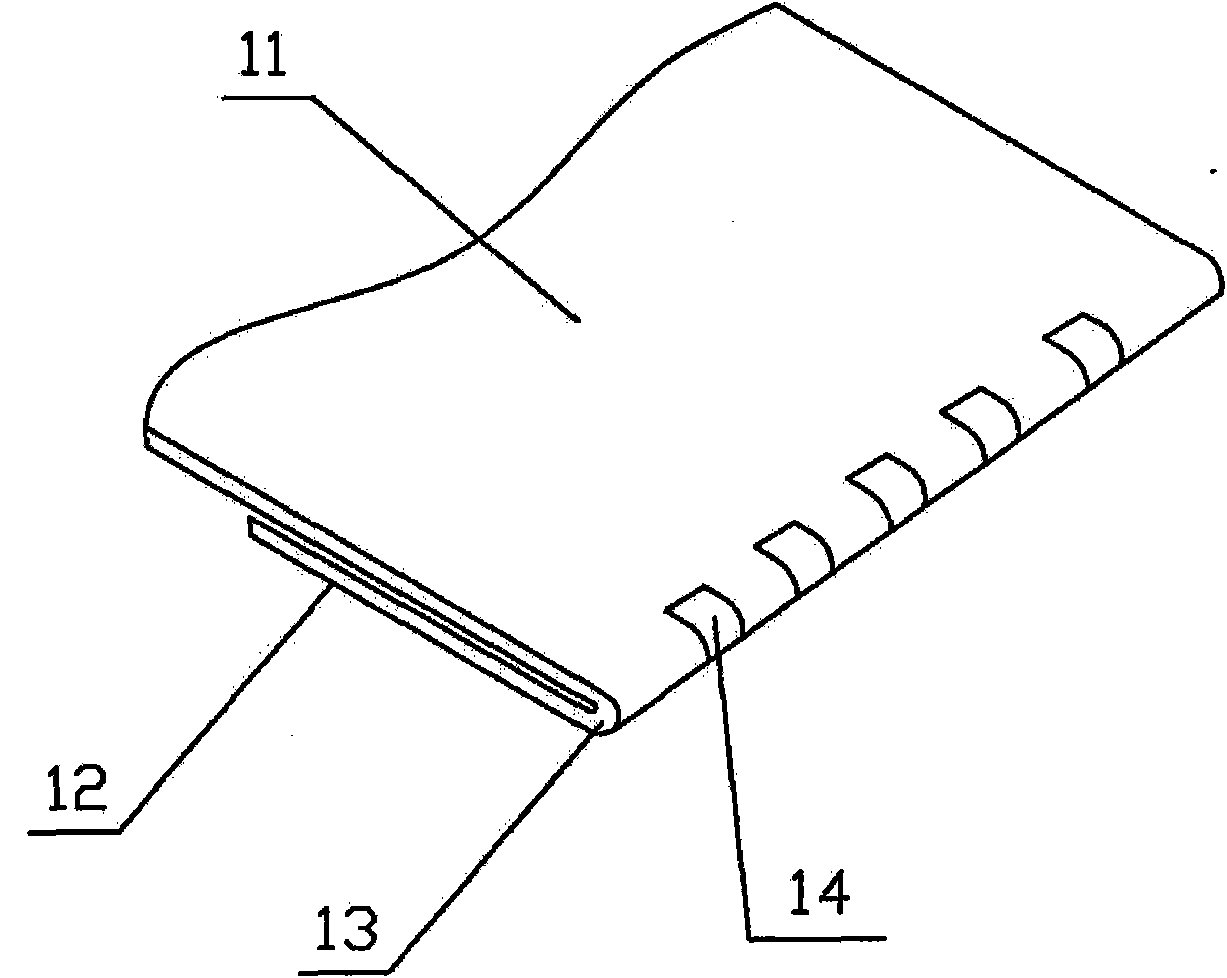

[0027] The embodiment of the present invention proposes a flexible circuit board, the structure of which is as follows figure 2 As shown, it includes a first body 11 of a flexible circuit board and a bending head 12; the bending head 12 is arranged side by side with the first body 11 of the flexible circuit board and forms a bending portion 13; the surface of the bending portion 13 Pads 14 are provided.

[0028] The embodiment of the present invention proposes a flexible circuit board, in which a bent part is formed, and pads are arranged on the surface of the bent part. In this way, compared with the single-sided FPC in the prior art, the pads of the FPC can be soldered to the pads on the surface of the PCB by manual welding or other welding methods. During soldering, the pads on the surface of the bent part and the pads on the surface of the PCB can be soldered together very simply, so as to reduce the difficulty of soldering and reduce the cost. At the same time, the FPC...

Embodiment 2

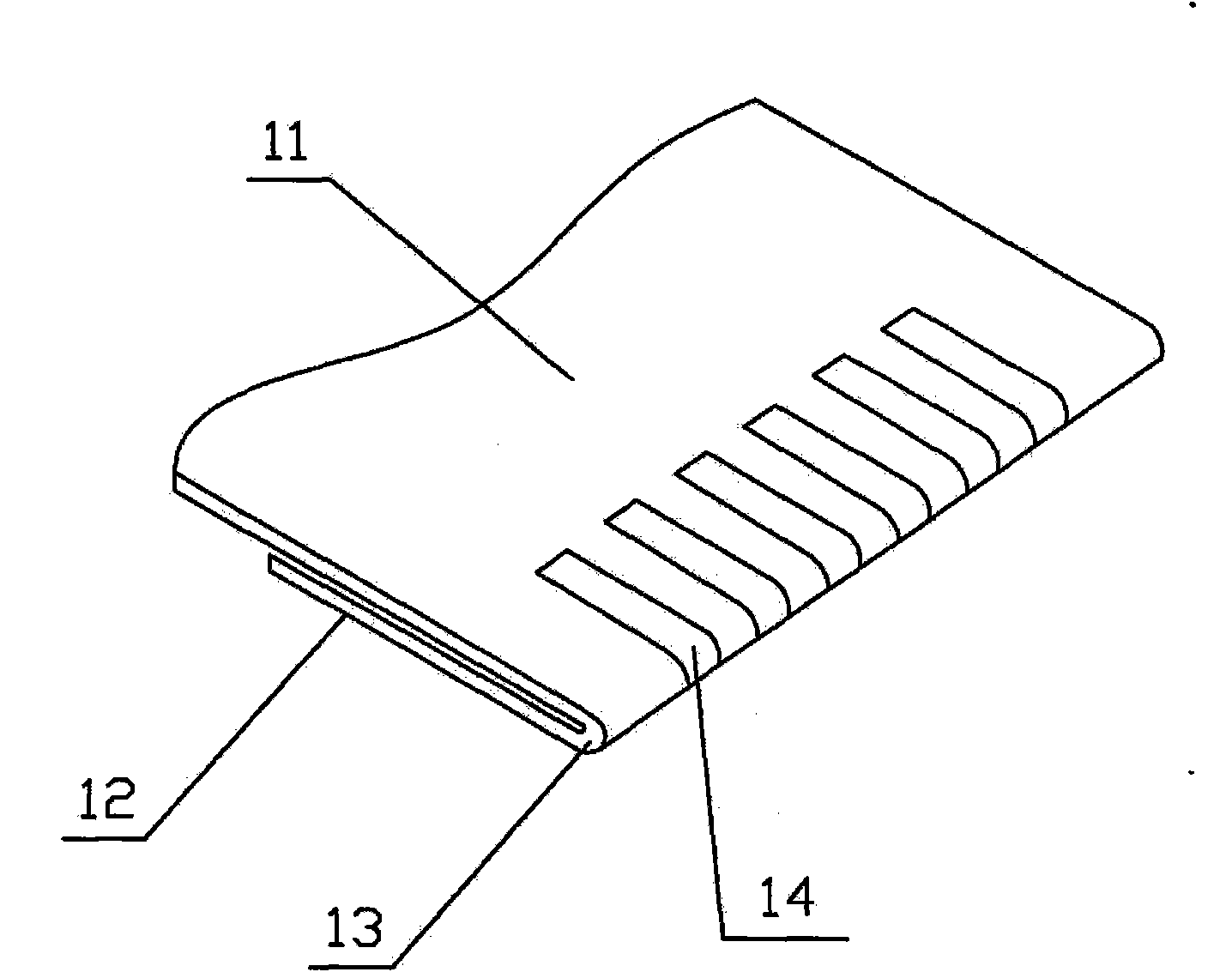

[0030] The second embodiment of the present invention proposes a flexible circuit board, the structure of which is as follows image 3 and Figure 4 As shown, it includes a first body 11 of a flexible circuit board and a bending head 12; the bending head 12 is arranged side by side with the first body 11 of a flexible circuit board and forms a bending portion 13; the U-shaped bending portion 13 is provided with pads 14 on the surface.

[0031] The bending head may be formed by bending one end of the flexible circuit board.

[0032] Wherein, the bent portion 13 is U-shaped. Of course, this is only an illustration of the embodiment of the present invention, and the bending portion can also be in other shapes, such as a V shape, which is not limited in the embodiment of the present invention.

[0033] Such as image 3 As shown, the pad 14 can extend a predetermined distance along the surface of the bending head 12, so that the contact area between the pad 14 and the pad on th...

Embodiment 3

[0039] The third embodiment of the present invention proposes a method for manufacturing a flexible circuit board, including:

[0040] A bending portion is formed between the first body of the flexible circuit board and the bending head, and a welding pad is formed on the surface of the bending portion.

[0041] The embodiment of the present invention proposes a method for manufacturing a flexible circuit board, which can form a bent portion of the flexible circuit board, and the surface of the bent portion has a welding pad. Compared with the single-sided FPC in the prior art, the flexible circuit board manufactured by adopting the method of the embodiment of the present invention can simply weld the pads of the FPC to the pads on the surface of the PCB by manual welding or other welding methods. During soldering, the pads on the surface of the bent portion and the pads on the surface of the PCB can be soldered together very simply; so as to reduce the difficulty of soldering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com