Electrostatic transfer head and manufacturing method thereof

A technology of electrostatic transfer and manufacturing method, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., and can solve problems such as low process yield, insufficient suction, and poor uniformity of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

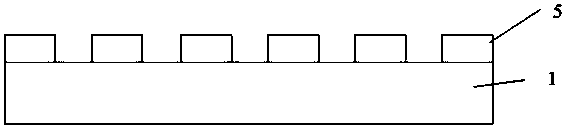

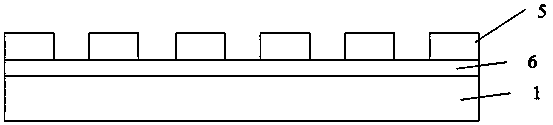

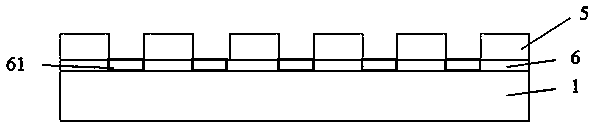

[0045] Such as Figure 8 As shown, Embodiment 1 of the present invention provides an electrostatic transfer head, including a substrate 1 , a patterned first metal layer 21 on the substrate 1 , and a dielectric layer 3 on the first metal layer 21 . Wherein the substrate 1 has a plurality of recesses 11 and a plurality of protrusions 12 arranged alternately, the dielectric layer 3 includes a first cavity 33 corresponding to the recesses 11, the first metal layer 21 is embedded in the protrusions 12 of the substrate 1, the second The upper surface of a metal layer 21 is flush with the upper surface of the substrate 1 .

[0046] Further, the dielectric layer 3 may be a one-layer or multi-layer structure, preferably, the dielectric layer 3 is a two-layer structure, the dielectric layer 3 includes a first dielectric layer 31 and a second dielectric layer 32, the first dielectric layer The electrical layer 31 is located on the second dielectric layer 32, the second dielectric layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com