Cu-based resistive random access memory manufacturing method and memory

A technology of resistive variable memory and memory, which is applied in the direction of static memory, digital memory information, information storage, etc., can solve the problems of Cu-based resistive variable memory reliability and low device yield rate, and achieve low device reliability and yield rate , Improve the effect of reliability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

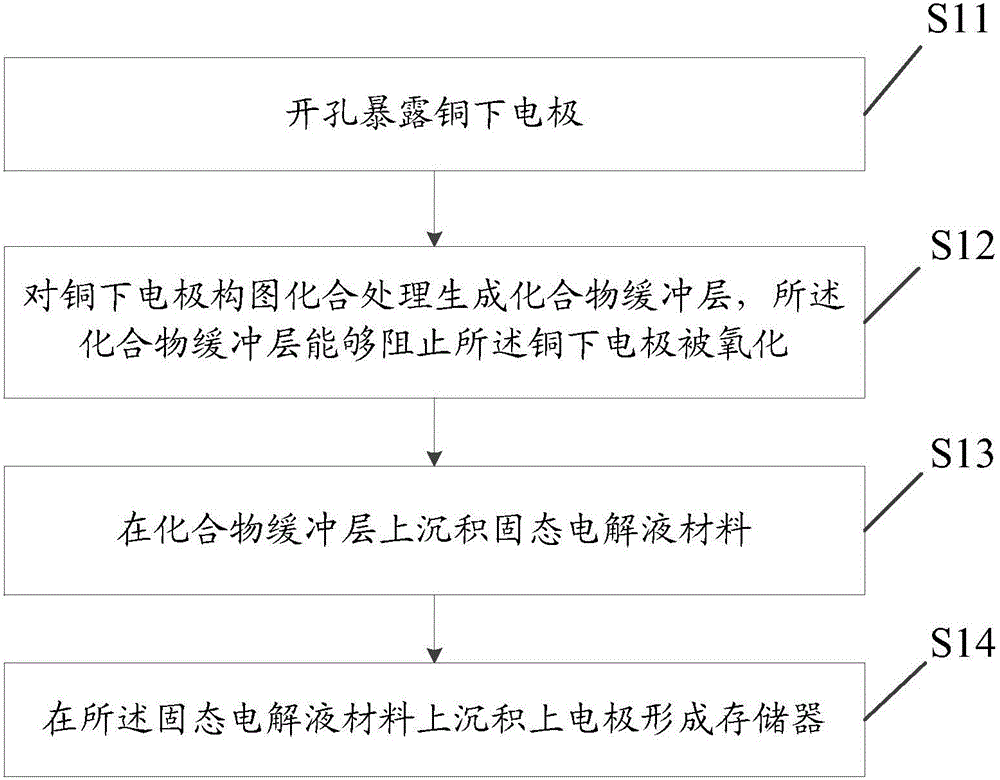

[0040] Please refer to figure 1 , the embodiment of the present application provides a method for preparing a Cu-based resistive variable memory, including:

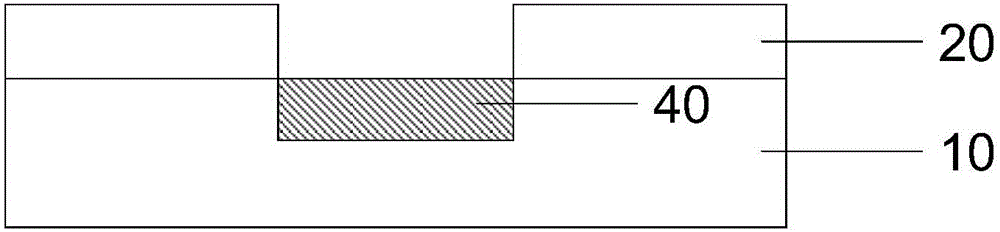

[0041] S12: Patterning and compounding the copper lower electrode to generate a compound buffer layer, the compound buffer layer can prevent the copper lower electrode from being oxidized;

[0042] S13: Depositing a solid electrolyte material on the compound buffer layer;

[0043] S14: Depositing an upper electrode on the solid electrolyte material to form a memory.

[0044] In the specific implementation process, in the embodiment of the present application, the pre-process S11 of preparing the Cu-based RRAM is completed before performing S12 patterning and compounding the copper lower electrode to form the compound buffer layer.

[0045] S11, the opening exposes the lower copper electrode.

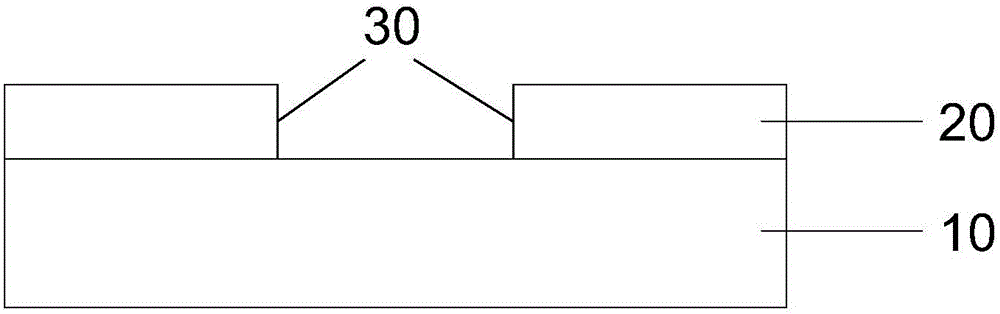

[0046] In this step, if figure 2 As shown, holes 30 are patterned on the dielectric layer 20 on the copper bottom electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com