V-shaped vacuum laminating device

A lamination device and vacuum technology, applied in lamination devices, chemical instruments and methods, telephone structures, etc., can solve the problems of low product yield, inability to cope with the stress release of folding, and short folding life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions and beneficial effects of the present invention will be clearer and more definite by further describing the specific implementation manners of the present invention in conjunction with the accompanying drawings of the specification below.

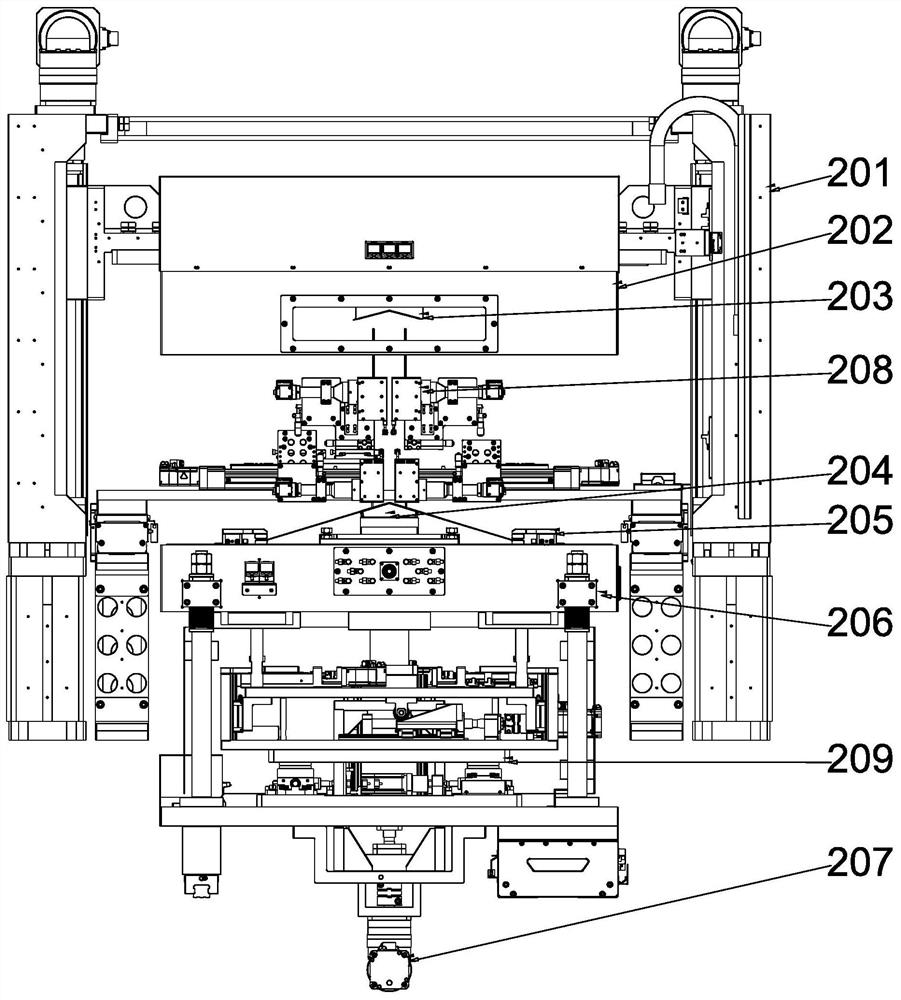

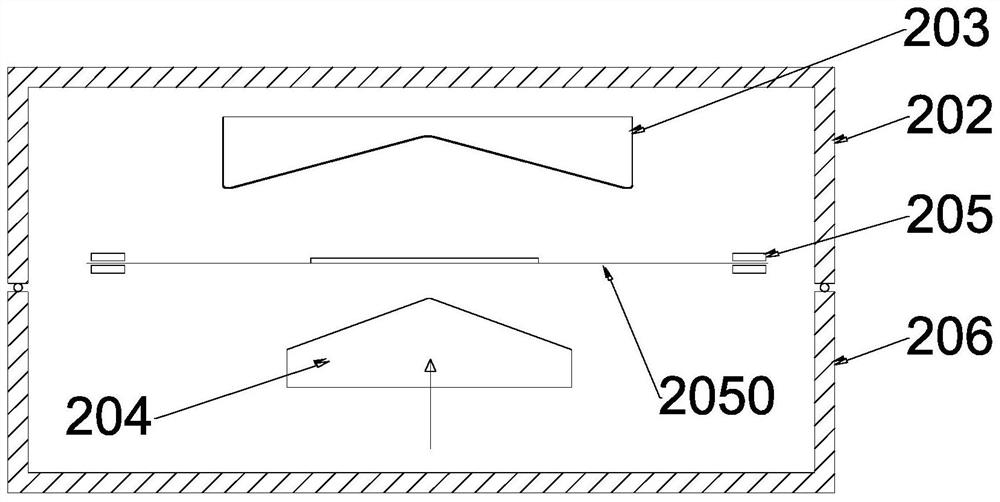

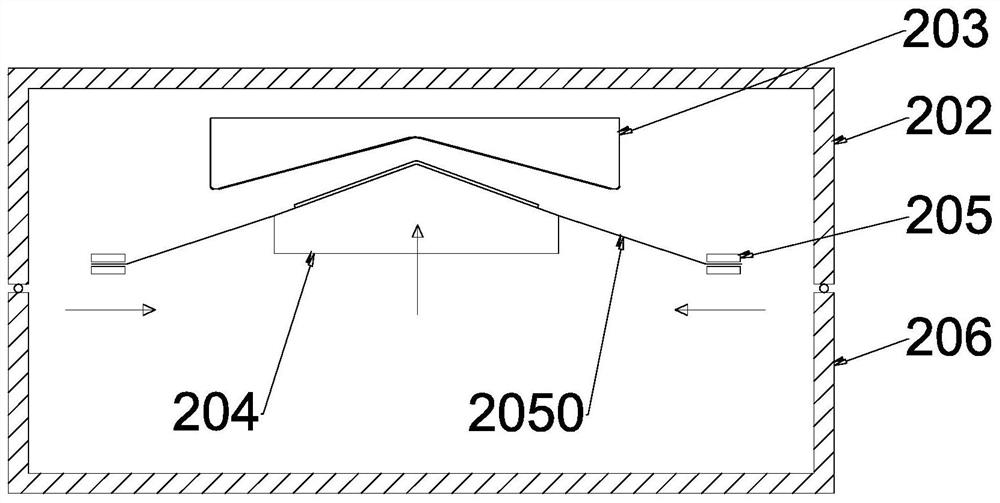

[0040] see Figure 1-14 A V-shaped vacuum bonding device of the present embodiment is shown, the V-shaped vacuum bonding device includes: an upper bonding mechanism, including an upper cavity, an upper cavity lifting Z axis that drives the upper cavity to lift, A V-shaped electrostatic adsorption platform set in the upper chamber for adsorbing material A; the lower bonding mechanism includes a lower chamber docked under the upper chamber, a carrier film for adsorbing material B arranged in the lower chamber, and a clamping bearing The supporting film clamping assembly on both sides of the film and straightening the supporting film, the profiling PAD arranged under the carrying film and docked with the V-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com