Dovetail mortise-tenon connection method between assembly parts in building project

A technology of construction engineering and connection method, applied in the direction of construction and building structure, can solve the problems of poor thermal insulation and sound insulation, difficult construction, high cost, etc. The effect of seismic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

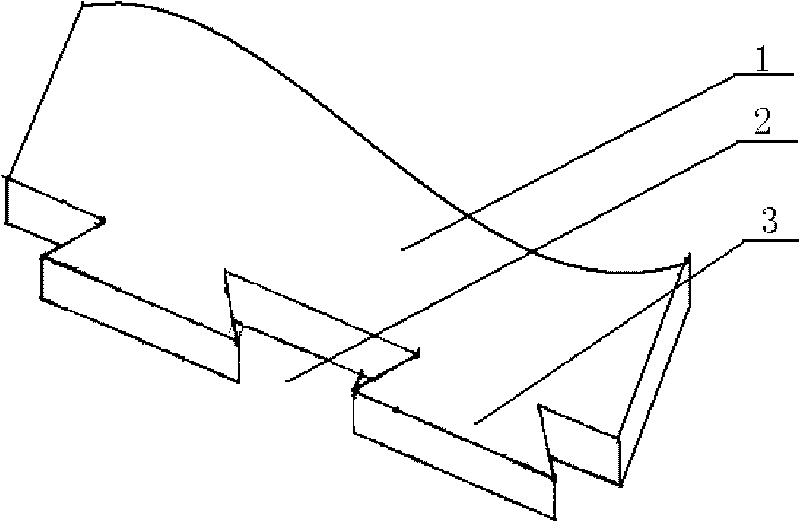

[0030] The connection method between the assemblies in the construction project designed in this embodiment is a dovetail mortise and tenon connection method, such as figure 1 As shown, dovetail-shaped tenons 2 are evenly spaced at the end of assembly 1, and dovetail-shaped mortise holes 3 are formed between two adjacent tenons 2; ~5000mm, the short side is 6~4000mm, and the height is 3~1000mm. In this embodiment, the long side is 10mm, the short side is 6mm, and the height is 3mm. The mortise 3 formed between the adjacent two tenons 2 is also trapezoidal Structure, the long side of the trapezoid with 3 mortise holes is 10mm, the short side is 6mm, and the height is 3mm, which matches the trapezoidal structure with mortise and tenon.

[0031] Various assembly parts 1 used in construction projects can be designed as mortise and tenon structures with dovetail tenon heads 2 at intervals, wherein the tenon head 2 of one assembly part 1 snaps into the mortise hole 3 of another asse...

Embodiment 2

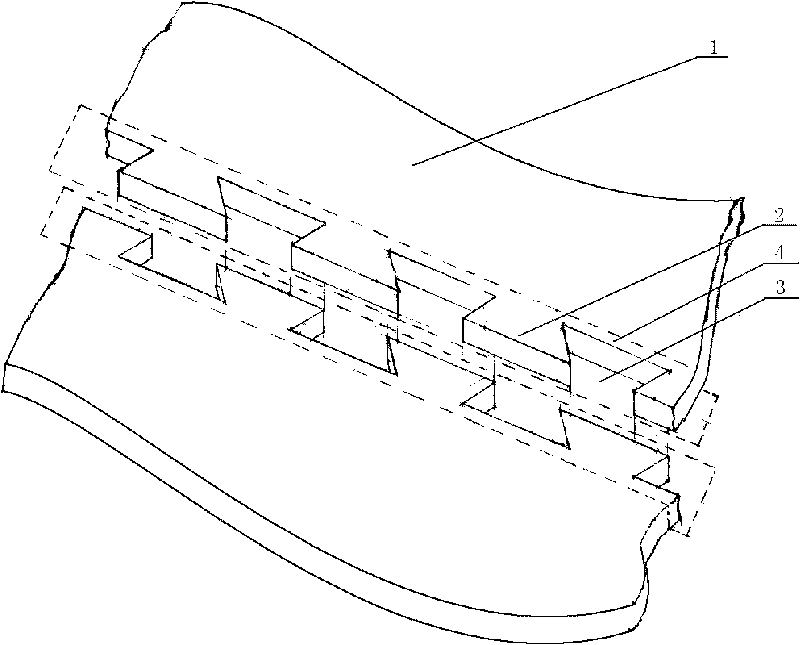

[0036] Such as figure 2 As shown, the dovetail mortise and tenon joints (shown in the dotted line in the figure) can be made separately at the mortise hole 3 and the tenon head 2 at the end of the assembly part 1. There is a mortise 2 and a mortise 3 formed between two spaced mortises 2, and the tenon fixing part 4 can be fixed at the joint of the assembly 1 as required, so that the mortise and tenon joint and the assembly 1 are connected together and fixed on the assembly The mortise and tenon joint on 1 can be directly processed and manufactured on the body of assembly 1 according to the needs, or it can be made into a permanent fixed connection or a detachable connection, which is easy to remove when the dovetail mortise and tenon connection is not needed. The dovetail mortise and tenon joints are arranged on the assembly according to the required quantity, position and form.

Embodiment 3

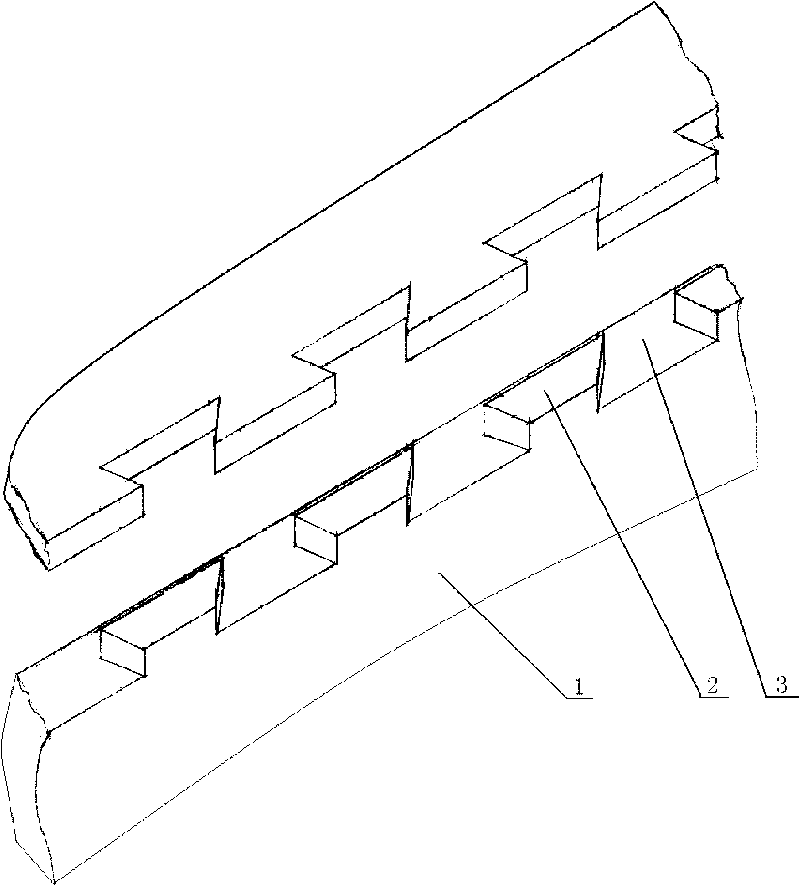

[0038] Such as image 3 As shown, this dovetail mortise and tenon connection method can also be applied to the connection between two assemblies 1 that are not in the same plane, one end of one assembly 1 is fixedly connected to the trapezoidal short side of tenon 2, and the other One end of 1 is fixedly connected with the trapezoidal plane of mortise 2, and the two assembly parts 1 are vertically connected through dovetail mortise and tenon; Vertical connection between straight shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com