Reinforcing treatment construction method for concrete beam-column joints with different strength grades of high-rise buildings

A technology for high-rise buildings and strength levels, applied in construction, building maintenance, building construction, etc., can solve the problems of neglecting the quality of concrete pouring, and the concrete strength value in the core area of beam-column joints does not meet the design requirements, so as to reduce shrinkage cracks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

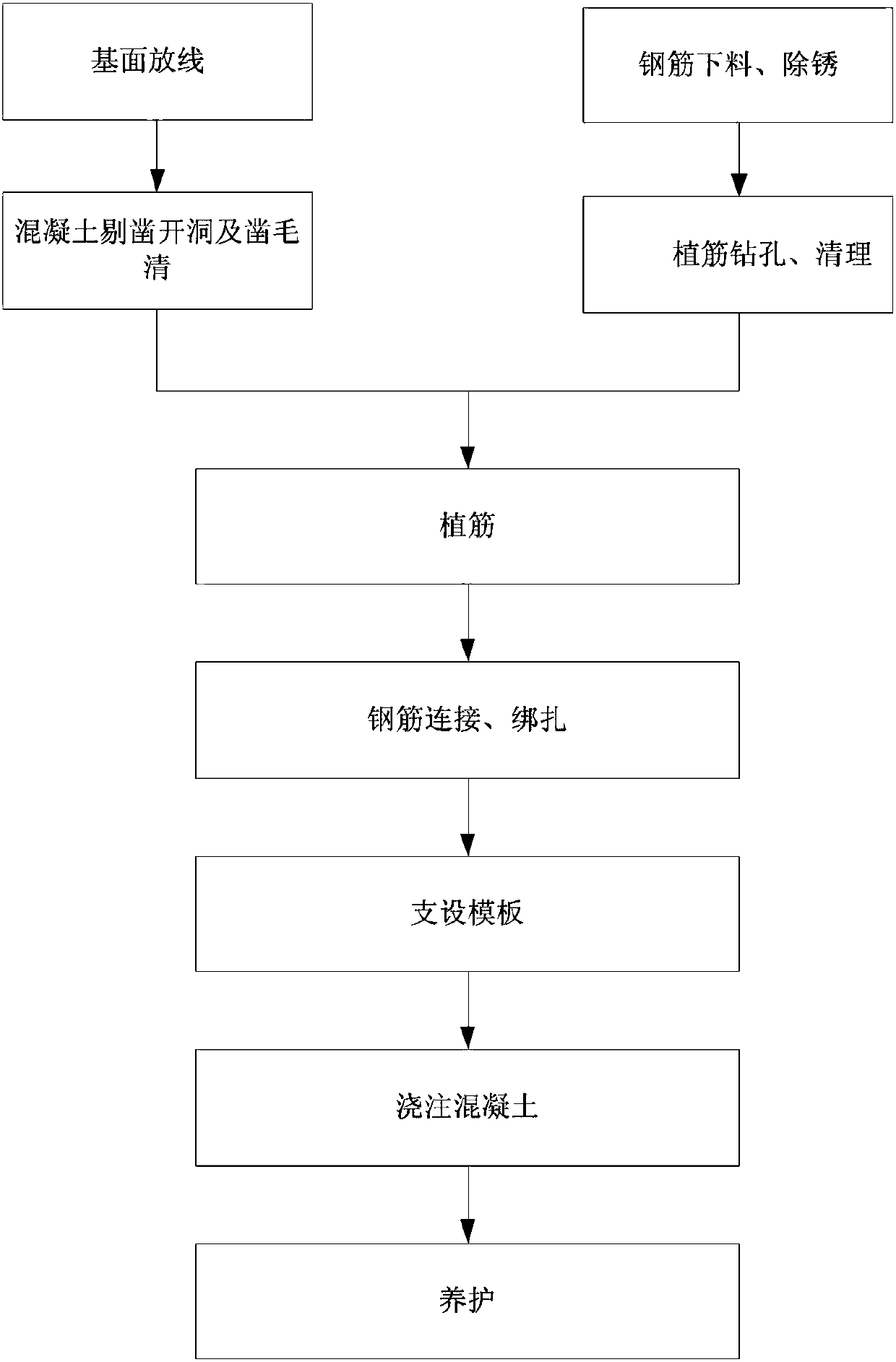

[0065] Such as figure 1 The construction method for reinforcement treatment at the concrete beam-column joints of different strength grades shown in the high-rise building, this embodiment discloses a specific construction method, including the following steps:

[0066] S1. Measure the wire setting on the base surface. The steps are as follows:

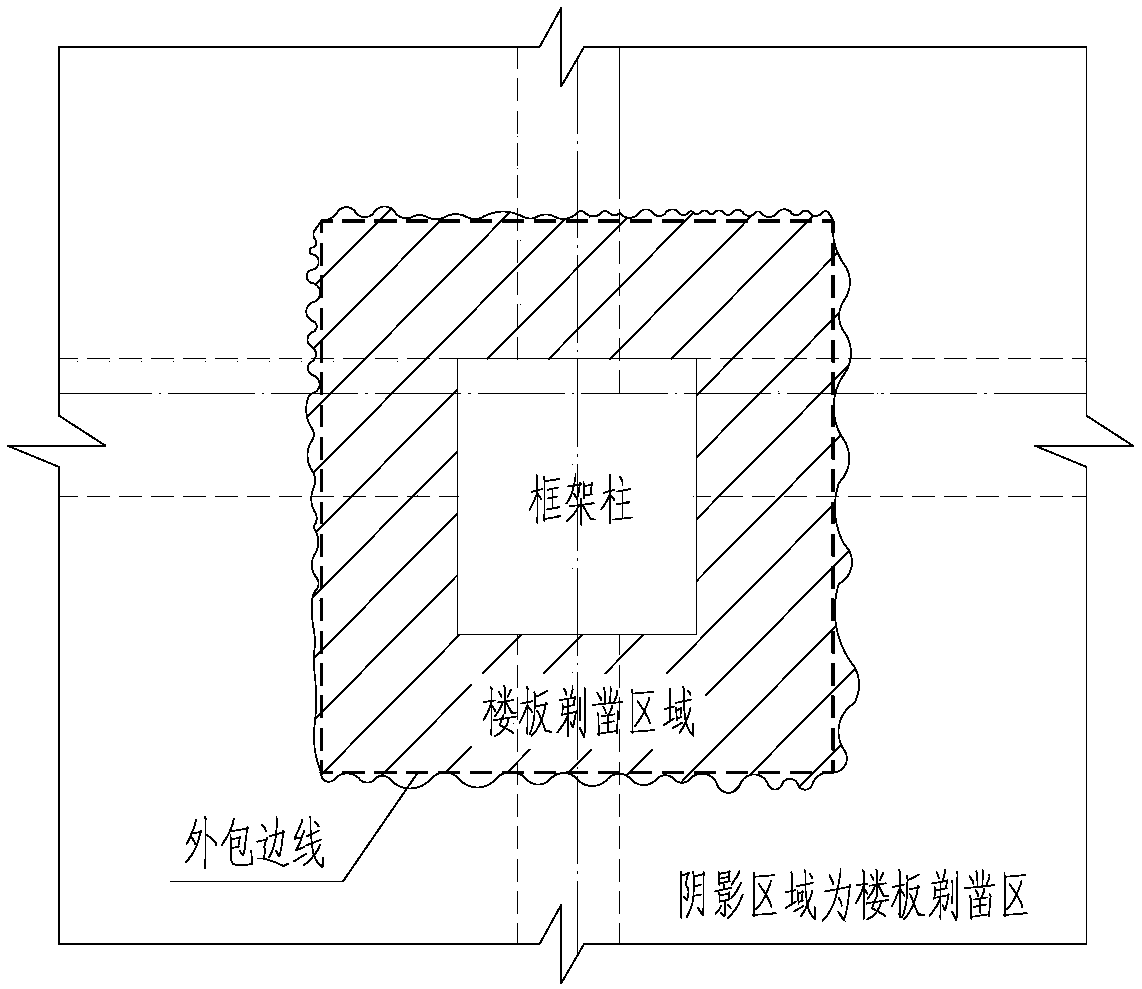

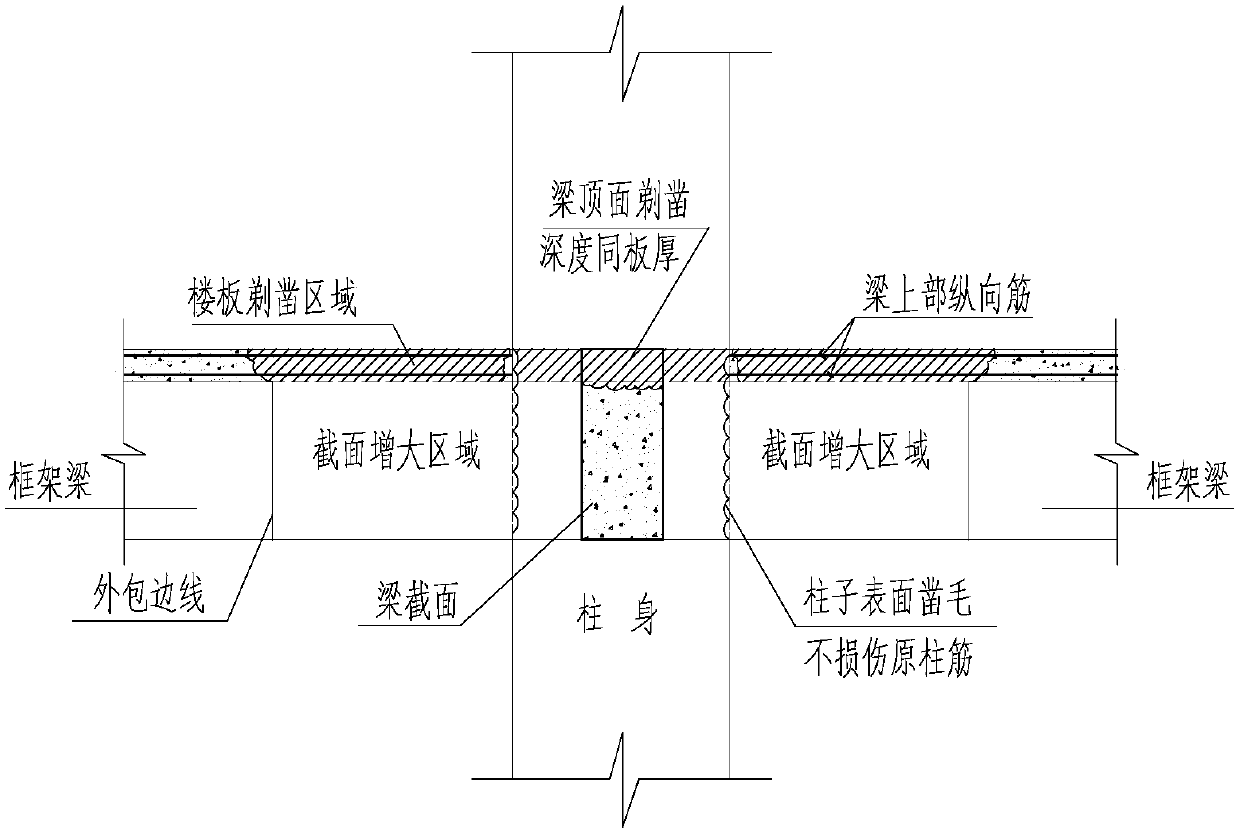

[0067] S101. According to the specific beam and column cross-sectional dimensions of the beam-column joints whose cross-section needs to be increased according to the statistics, determine the range of shaving the floor slab and snap the line.

[0068] S102. Determine the position of the outer covering wire of the beam according to the requirement of increasing the section size and snap the wire.

[0069] S103. According to the requirements, determine the location of the reinforcement on the beam, the location of the main reinforcement of the beam at the location of the reinforcement, and the layout line of the location of each stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com