Plant fibre reinforced foam composite material with hard polyurethane structure and production thereof

A technology of rigid polyurethane and composite materials, which is applied in the field of materials, can solve the problems that products are not widely used, and achieve the effects of reducing product costs, broad application prospects, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

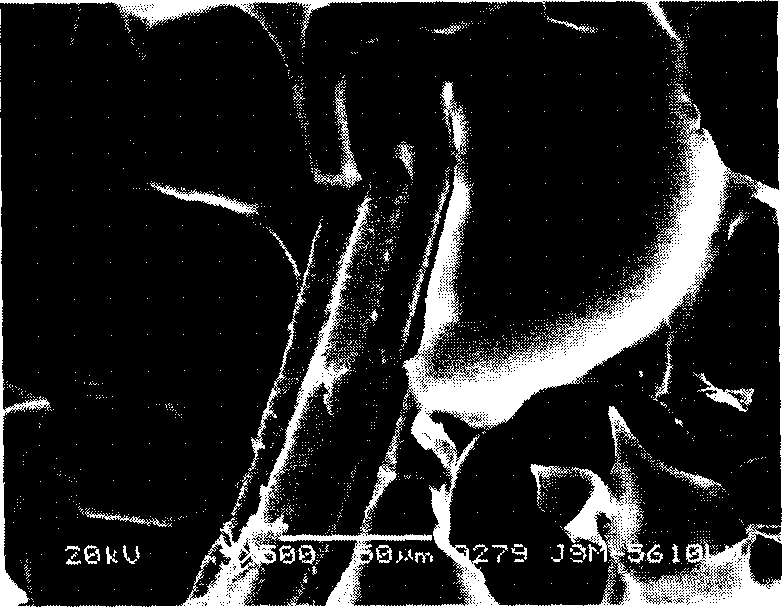

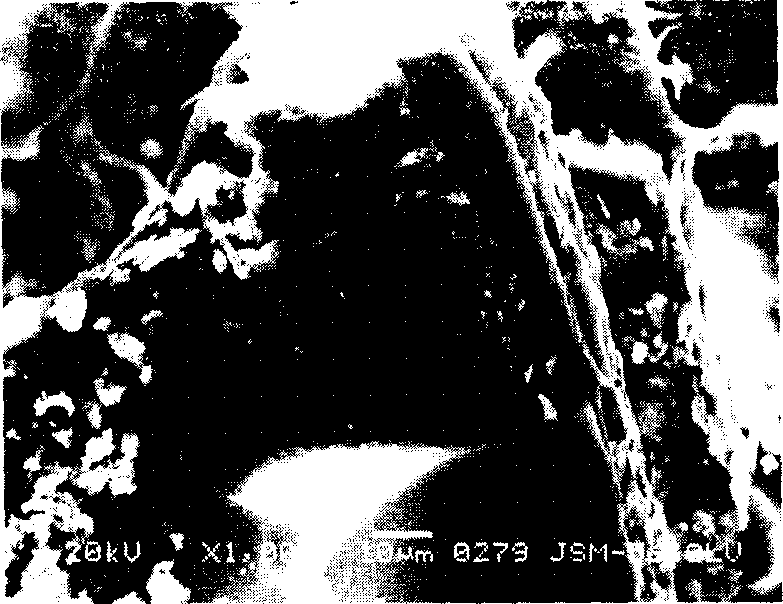

Image

Examples

specific example 1

[0047] Concrete example 1: the first step, weigh according to following proportioning, in the raw material mixed liquor after raw material preparation, add the jute chopped fiber that is not through surface treatment, and wherein fiber length is respectively 3mm, 5mm, 10mm.

[0048] 100 parts of polyether polyol resin (hydroxyl value 400-600 mgKOH / g), 115 parts of polyphenyl polymethyl polyisocyanate, 0.6 part of triethanolamine, 0.1 part of dibutyltin dilaurate, 3 parts of dimethyl siloxane Parts, 5 parts of fluorotrichloromethane (HCFC-141b) and 3 parts of jute fiber (untreated).

[0049] In the second step, the reinforced rigid polyurethane structural foam composite material is made by using the aforementioned one-step molding process.

specific example 2

[0050] Concrete example 2: in concrete embodiment 1, in the raw material mixed solution after raw material preparation, add the jute chopped fiber through surface treatment, wherein fiber length is respectively 3mm, 5mm, 10mm. Other implementation process conditions and process are identical with example 1.

specific example 3

[0051] Concrete example 3: the first step, weigh according to following proportioning, add the jute chopped fiber through surface treatment in the raw material mixture after raw material preparation, wherein fiber length is respectively 3mm.

[0052] 100 parts of polyether polyol resin (hydroxyl value 400-600 mgKOH / g), 115 parts of polyphenyl polymethyl polyisocyanate, 0.6 part of triethanolamine, 0.1 part of dibutyltin dilaurate, 3 parts of dimethyl siloxane 1 part, 5 parts of fluorotrichloromethane (HCFC-141b), 10 parts of ceramic hollow microspheres and 1 part of jute fiber (treated)

[0053] In the second step, the reinforced rigid polyurethane structural foam composite material is made by using the aforementioned one-step molding process.

[0054] Density and performance of above-mentioned embodiment gained product are as shown in table 1:

[0055] Specific example 1

Specific example 2

Specific example 3

fiber length

(mm)

3

5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com