Preparation method of wood plastic material

A technology of wood-plastic materials and thermoplastics, applied in the field of preparation of wood-plastic materials, can solve the problems of weakening the mechanical properties of materials, insufficient strength of products, and many bubbles in products, and achieve the effects of high toughness, low cost and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

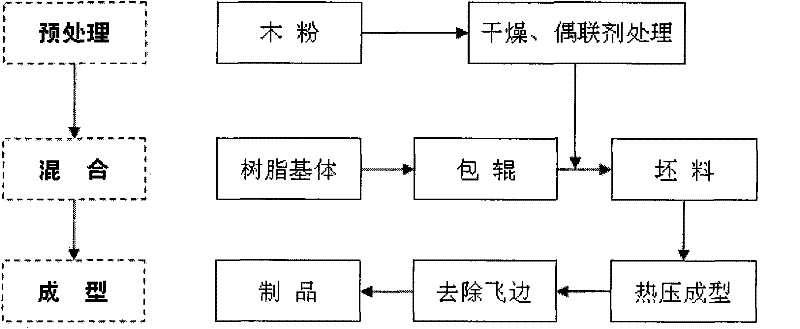

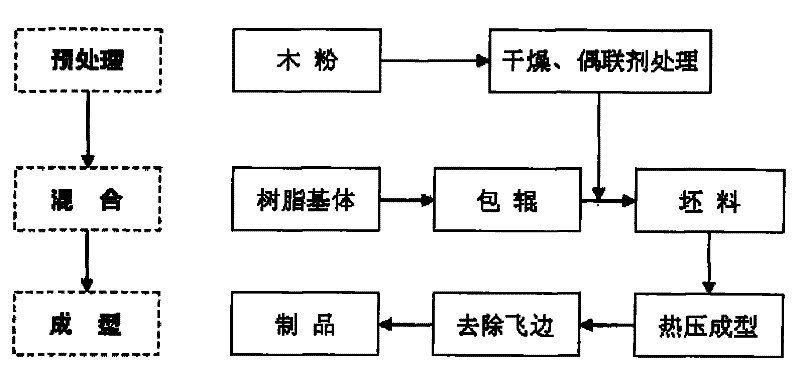

[0028] The preparation method of the wood-plastic material of the present invention is characterized in that: select the following raw materials, mix the following raw materials at a high speed, and then carry out kneading on an open mill to produce a billet, and finally pass the prepared billet through a flat vulcanizing machine Carry out thermoforming;

[0029] Raw material weight content (parts)

[0030] Thermoplastic 100

[0031] Wood powder or plant fiber 20~50

[0032] Silane or aluminate coupling agent 0.4~0.9

[0033] Ethylene-vinyl acetate 4~15

[0034] Paraffin 0.8~1.5.

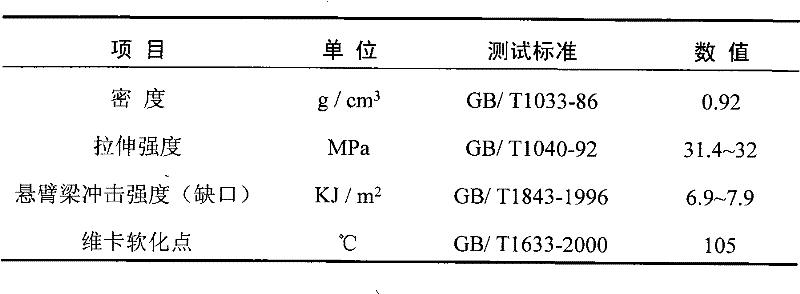

Embodiment 1

[0036] Prepare materials according to the following weight fractions

[0037] Raw material weight content (parts)

[0038] Polypropylene 100

[0039] poplar wood powder 30

[0040] Aluminate coupling agent 0.5

[0041] Ethylene-vinyl acetate 10

[0042] Paraffin 1

[0043] Among them, polypropylene is selected as thermoplastic, and polypropylene is extrusion grade. Torque rheology test shows that the maximum torque is 50-60N m. Poplar wood powder is selected as wood powder or plant fiber, and the particle size is 100 mesh ( About 165μm), ethylene-vinyl acetate (EVA), VA content 18%, paraffin wax is translucent granular;

[0044] 2) First modify the poplar wood powder, dry the poplar wood powder at 120°C for 4 hours, dilute the aluminate coupling agent with absolute ethanol or acetone or other suitable diluents, mix it with the wood powder evenly, and then bake Dry;

[0045] 3) Use a double-roller mill for mixing. Control the roll temperature at 150 / 135°C (A roll / B roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com