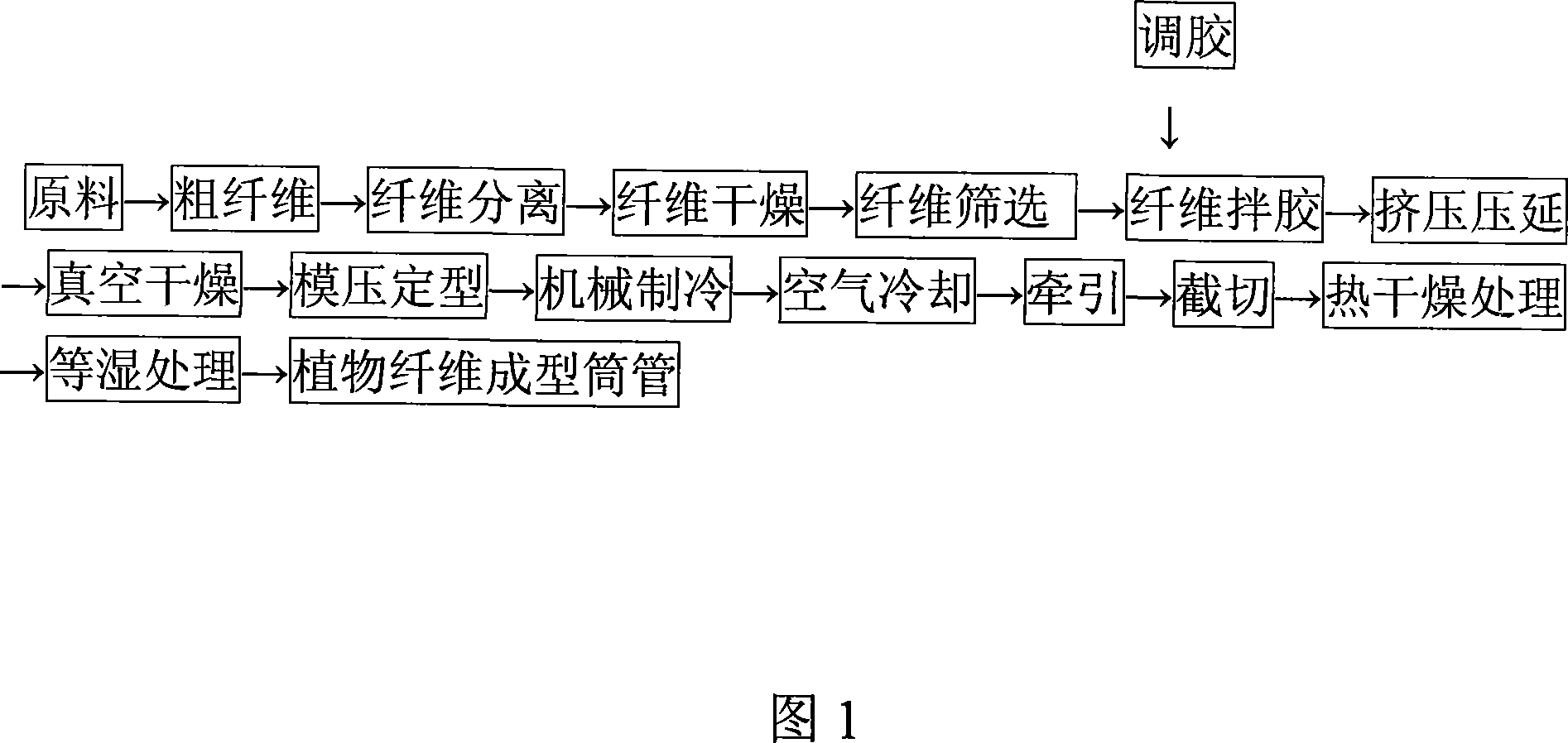

Method of processing vegetable fibre formed pipe and the preparing system

A plant fiber and processing method technology, applied in the direction of wood processing equipment, pretreatment of molding materials, hollow objects, etc., can solve the problems that cannot be made into tube-shaped products, so as to omit the papermaking process, reduce processing procedures, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

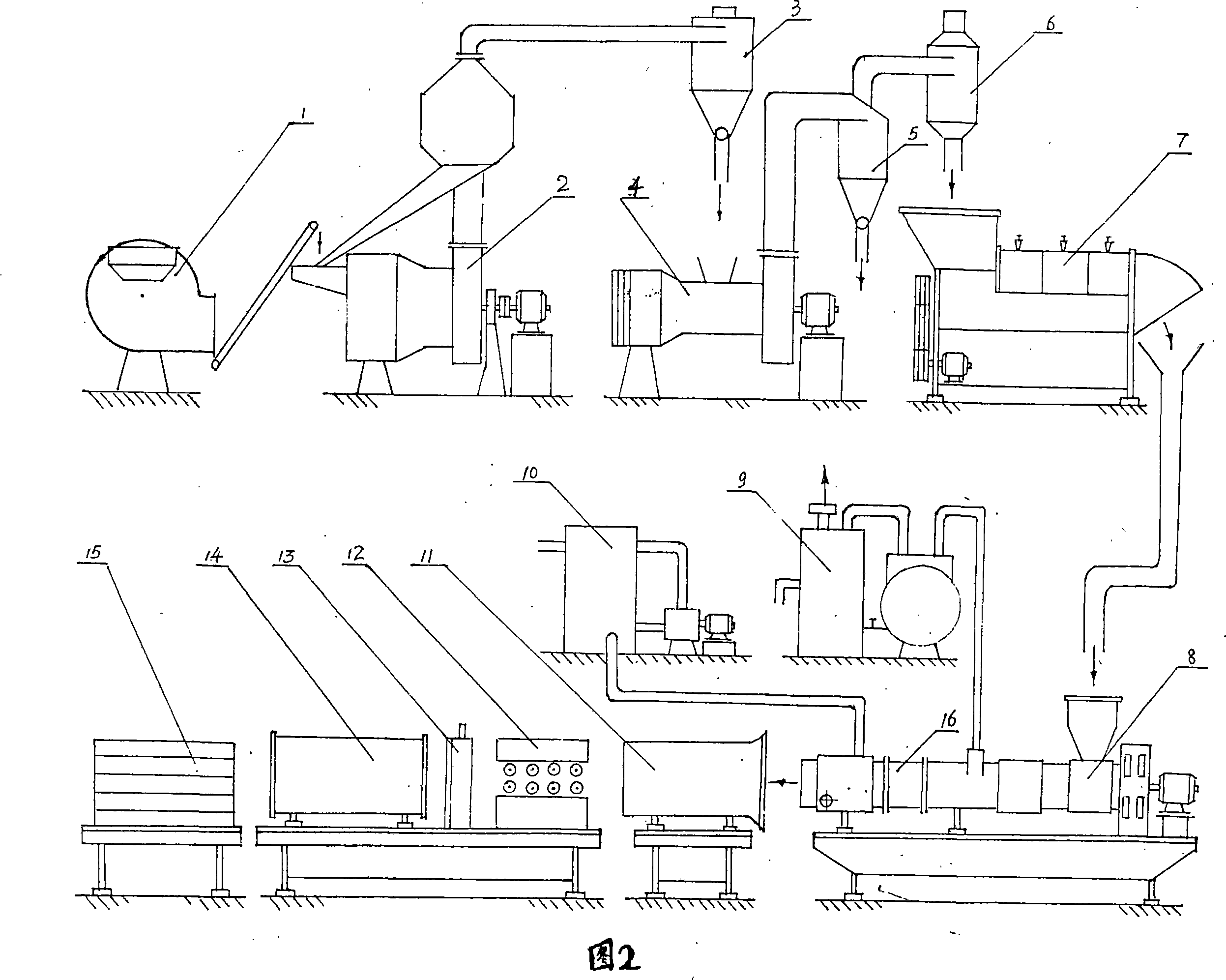

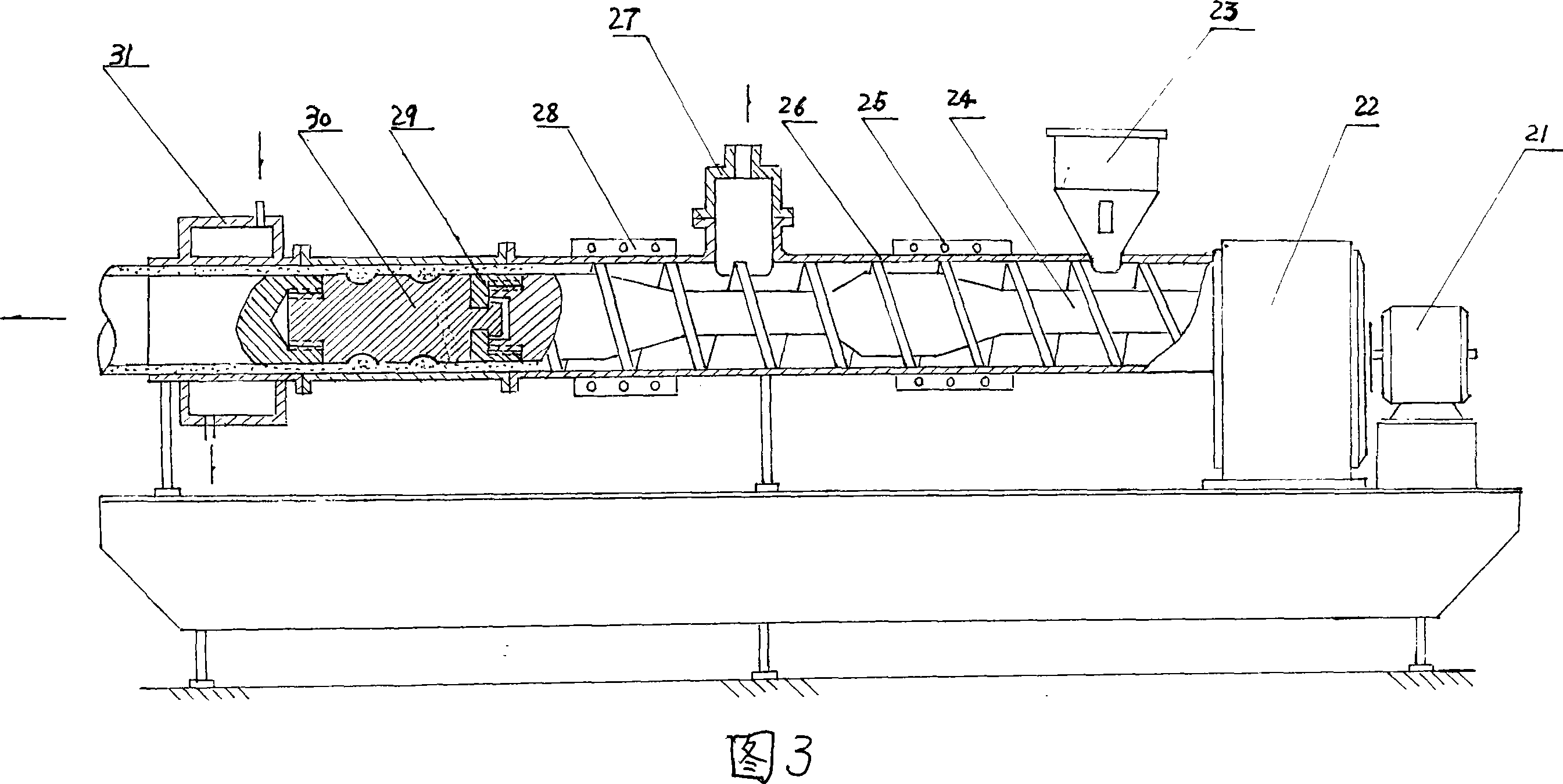

[0036]As shown in Figure 2, the outlet of the plant fiber processing device corresponds to the inlet of the spray glue mixer 7 or is connected through a pipeline, and the outlet of the spray glue mixer 7 corresponds to the entrance of the extrusion molding device or passes through the delivery pipeline connected. The plant fiber processing device includes a coarse fiber crusher 1, a fiber separator 2, a fiber wind separator 3, a fiber dryer 4, a fiber filter 5 and a fiber stocker 6, and the outlet of the coarse fiber crusher 1 is transported The belt or pipe is connected to the inlet of the fiber separator 2, the inlet of the fiber air separator 3 is connected to the outlet and the inlet of the fiber separator 2 through pipes, and the outlet of the fiber air separator 3 corresponds to the upper and lower inlets of the fiber dryer 4 or Connected by pipelines, the fiber dryer 4 is connected with the fiber stocker 6 through the fiber screen 5, and the required material is stored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com