Double-electric-drive type crawler chassis

A crawler chassis and crawler technology, applied in the field of dual electric drive crawler chassis, can solve the problem of high labor cost, and achieve the effects of improving transportation capacity, strong bearing capacity, and high lightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

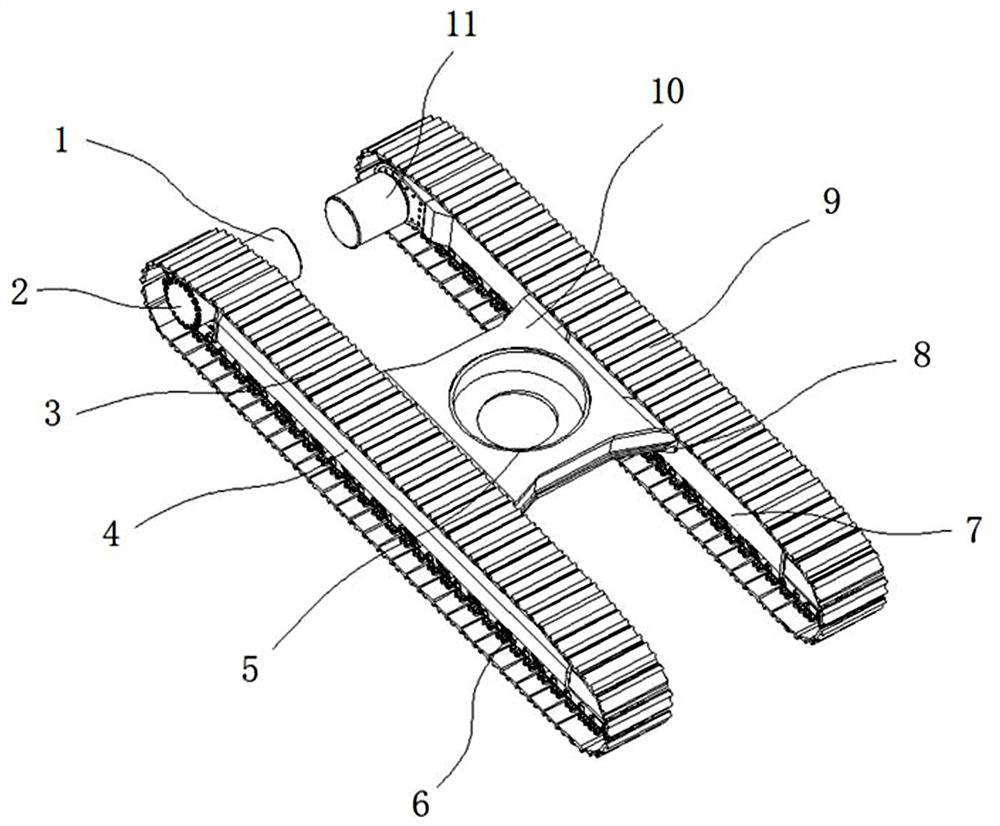

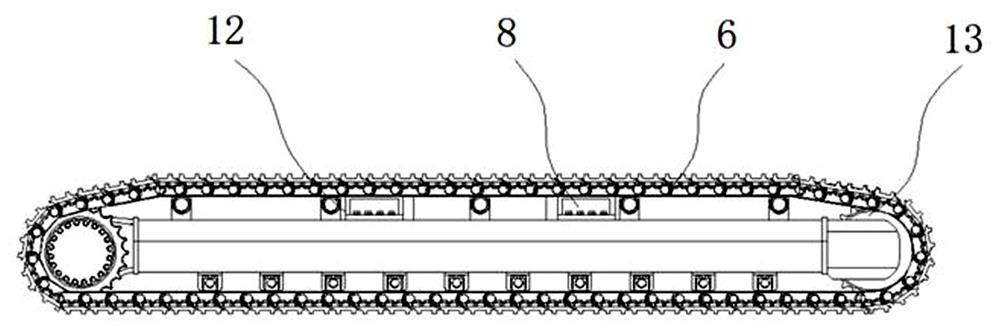

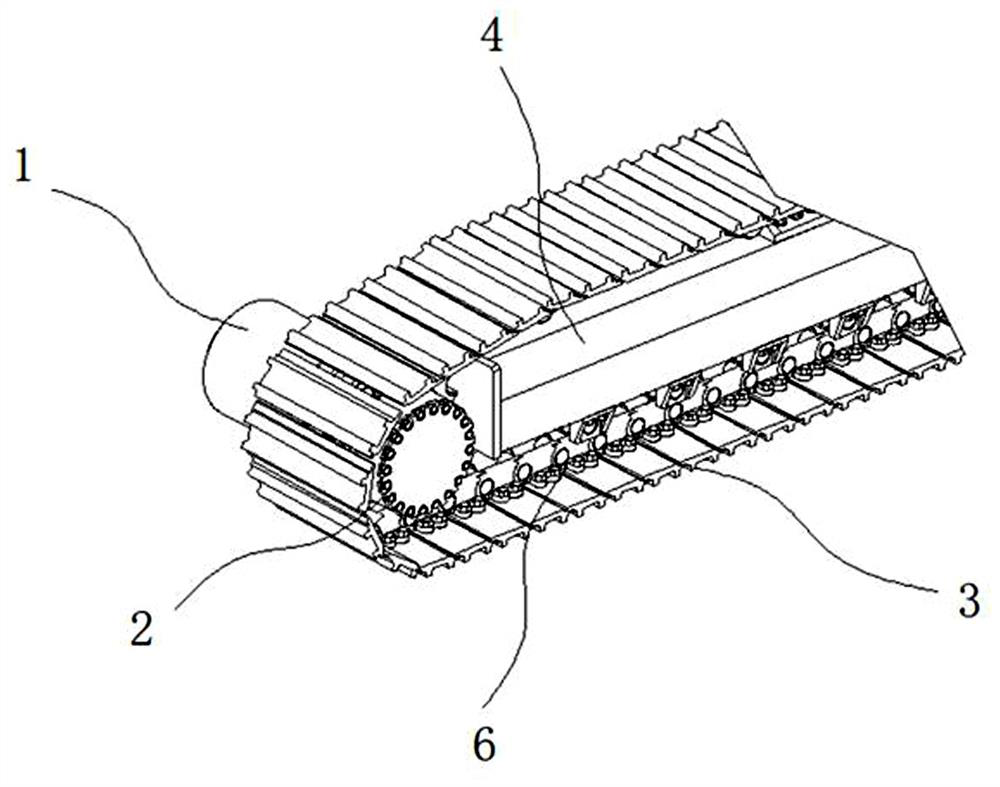

[0023] Example 1: See Figure 1-4 , dual electric drive crawler chassis, including a first crawler 3 and a second crawler 9, one end of the first crawler 3 is provided with a second crawler 9, the inside of the first crawler 3 is provided with a first steel beam 4, the second crawler 9 A second steel beam 7 is arranged inside the interior, and one side of the first steel beam 4 and the second steel beam 7 are respectively movably connected with a drive sprocket 2, and the central axis of the drive sprocket 2 is fixedly connected with a first drive motor 1 and a drive sprocket 2 respectively. The second drive motor 11, the other side of the first steel beam 4 and the second steel beam 7 are respectively movably connected with driven sprockets 13, the inner sides of the first crawler belt 3 and the second crawler belt 9 are respectively provided with chain rails 6, and the driving The sprocket 2 and the driven sprocket 13 are engaged with the chain rail 6 respectively, and an in...

Embodiment 2

[0028] Embodiment 2: A crawler frame 10 is plugged between the installation grooves 12, and the two ends of the crawler frame 10 are fixedly connected with mounting pieces 8, and the mounting pieces 8 are respectively fixedly connected with the first steel beam 4 and the second steel beam 7, and the track frame The inside of 10 is provided with fixing groove 5, which can be disassembled;

[0029] The fixing groove 5 is a circular through groove, and the mounting piece 8 is fixedly connected with the first steel beam 4 and the second steel beam 7 by bolts respectively, and the connection is stable and does not shake;

[0030] Specifically, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the crawler frame 10 is embedded in the installation groove 12, and is fixedly connected with the first steel beam 4 and the second steel beam 7 through the installation pieces 8 at both ends, and is always kept horizontal with the first steel beam 4 and the second steel beam ...

Embodiment 3

[0031] Embodiment 3: The first steel beam 4 and the second steel beam 7 are embedded with a motor control unit, which is easy to operate and real-time control;

[0032] The first crawler belt 3 and the second crawler belt 9 have the same length, and the width of the first crawler belt 3 and the second crawler belt 9 is larger than the first steel beam 4 and the second steel beam 7, and the power is strong;

[0033] Specifically, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the first drive motor 1 and the second drive motor 11 turn in the opposite direction after being energized, and the speed of the speed can be adjusted through the built-in frequency converter to realize flexible steering. The operation is simple, and the first drive motor 1 and the second drive motor 11 are directly connected. Drive the drive sprocket 2 directly on the central axis of the drive sprocket 2, which can realize real-time control of the first drive motor 1 and the second dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com