Method for preparing geopolymer gelled material from heavy metal gypsum

A geopolymer and cementitious material technology, applied in the fields of environmental protection and material engineering, can solve problems such as calcium sulfate heavy metal pollution, and achieve the effect of high compressive strength and increased compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

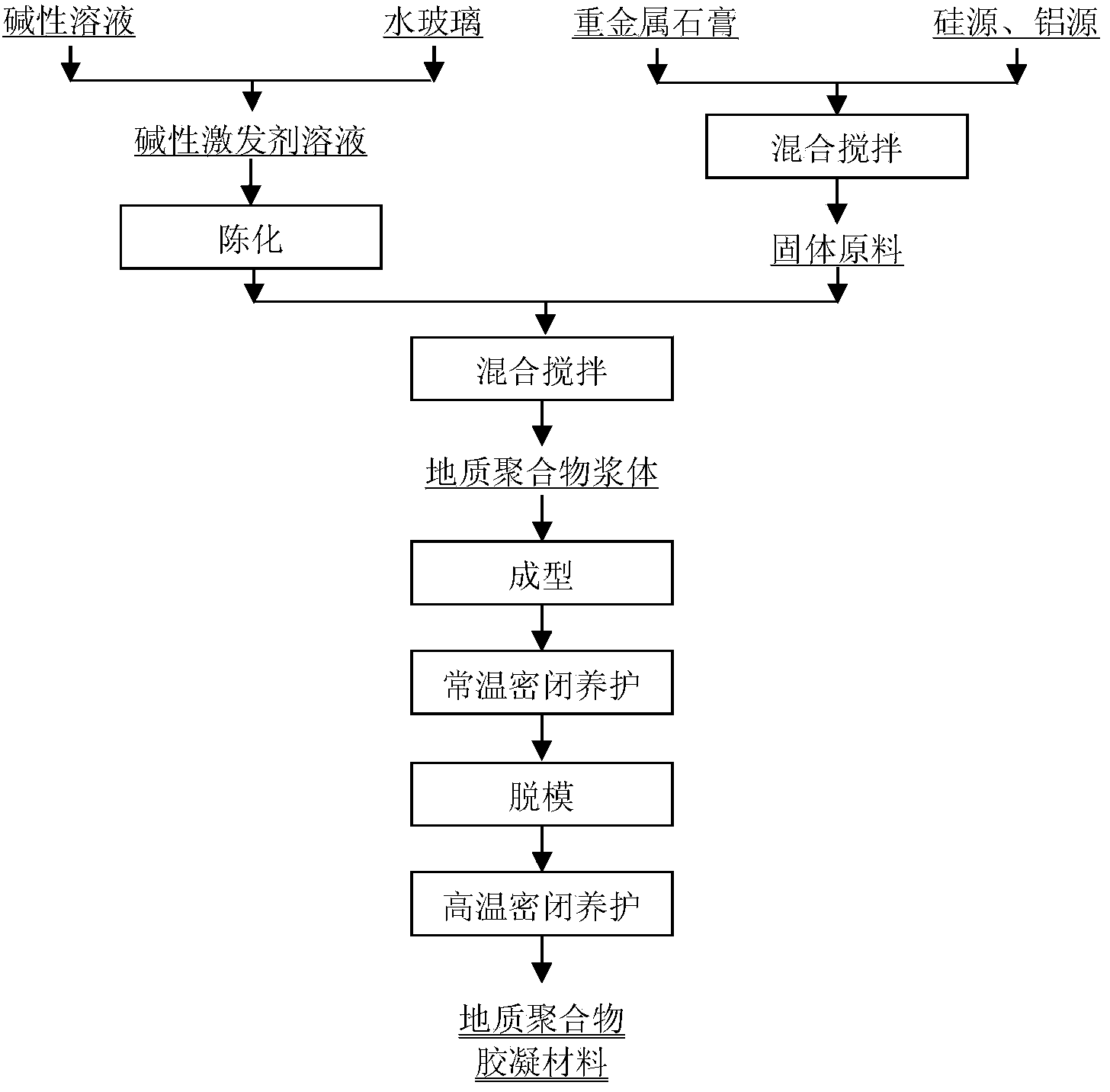

Method used

Image

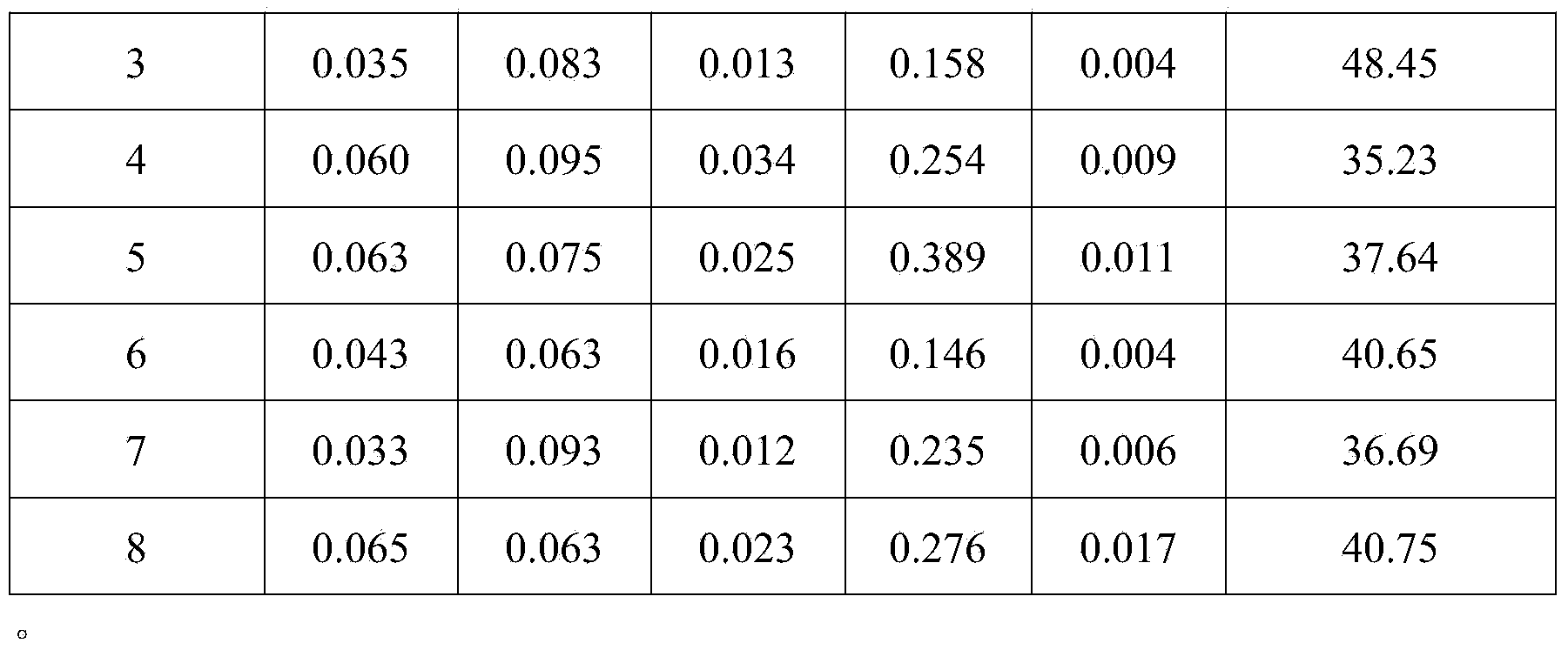

Examples

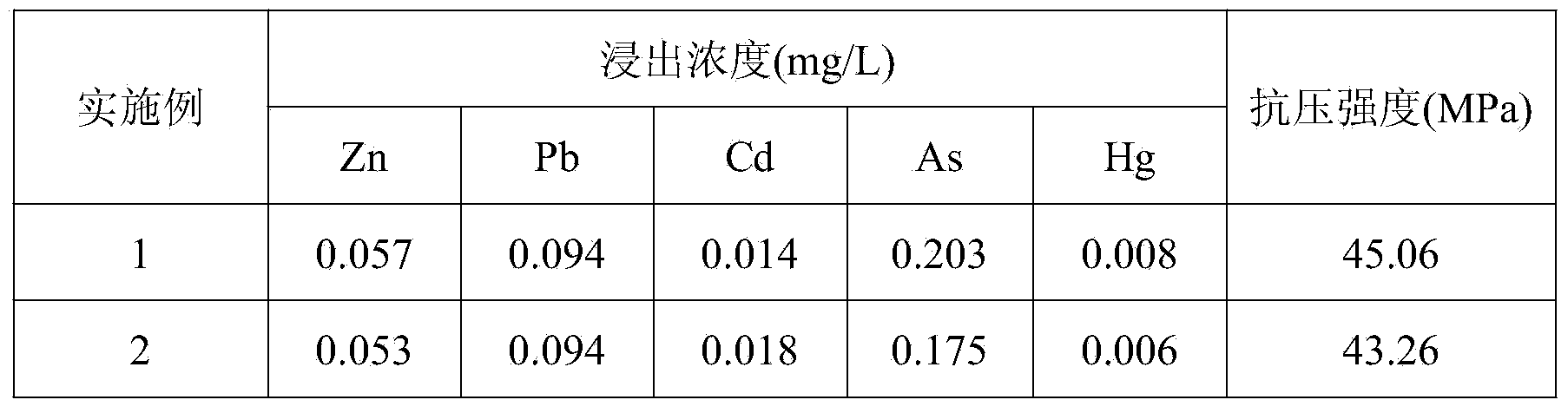

Embodiment 1

[0019] Configure activator solution with NaOH, water glass and water, mix and stir to obtain alkaline activator solution, age for 24h, the total solid content in the activator solution is 33.00wt% and the modulus is 1.10; fly ash , coal gangue, and heavy metal gypsum are respectively ball milled to a volume median diameter of 100±10 μm, mixed and stirred evenly to obtain solid raw materials, the solid raw materials contain 60.00wt% of fly ash, 20.00wt% of coal gangue, and 20.00wt% of heavy metal gypsum; The aged alkaline activator solution was mixed with solid raw materials and stirred for 10 minutes to obtain a geopolymer slurry, which was transferred to a mold for molding and sealed and maintained at room temperature for 24 hours before demolding, wherein the alkaline activator solution was mixed with The mass ratio of solid raw materials is 0.55; the geopolymer after demoulding is cured under high temperature conditions for 48 hours, and the curing temperature is 85°C; the g...

Embodiment 2

[0021]Configure the activator solution with NaOH, KOH, water glass, water, mix and stir to obtain an alkaline activator solution, age for 48h, and the total solid content in the activator solution is 36.00wt% and the modulus is 1.20; Fly ash and heavy metal gypsum were respectively ball milled until the volume median diameter was 80±10 μm, mixed and stirred evenly to obtain solid raw materials, which contained 80.00wt% of fly ash and 20.00wt% of heavy metal gypsum; the aged alkali The alkaline activator solution was mixed with the solid raw material and stirred for 10 minutes to obtain a geopolymer slurry, which was transferred to a mold for molding, sealed and maintained at room temperature for 12 hours, and then released from the mold. The mass ratio of the alkaline activator solution to the solid raw material was 0.40; the geopolymer after demoulding was cured under high temperature conditions for 18 hours, and the curing temperature was 80°C; the geopolymer after high-tempe...

Embodiment 3

[0023] Configure activator solution with NaOH, water glass and water, mix and stir to obtain alkaline activator solution, age for 24h, the total solid content in the activator solution is 39.00wt% and the modulus is 1.00; fly ash, The heavy metal gypsum is respectively ball-milled to a volume median diameter of 60±10 μm, mixed and stirred evenly to obtain a solid raw material, the solid raw material contains 85.00wt% of fly ash and 15.00wt% of heavy metal gypsum; the alkaline activator solution after aging Mix with solid raw materials and stir for 10 minutes to obtain geopolymer slurry, which is transferred to a mold for molding and airtight curing at room temperature for 20 hours before demoulding, wherein the mass ratio of alkaline activator solution to solid raw materials is 0.45; The demoulded geopolymer was cured under high temperature conditions for 24 hours, and the curing temperature was 90°C; the geopolymer after high-temperature airtight curing was placed in the air u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com