Solid waste-based sulphoaluminate cement solidified base material of medium and low radioactive nuclear waste and preparation method thereof

A sulfoaluminate-based and low-radioactive technology is applied in the field of solid waste-based sulfoaluminate cement curing substrate and its preparation, which can solve the problems of short setting time, low cost and limited performance, and achieve strong curing effect, Reduced production cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

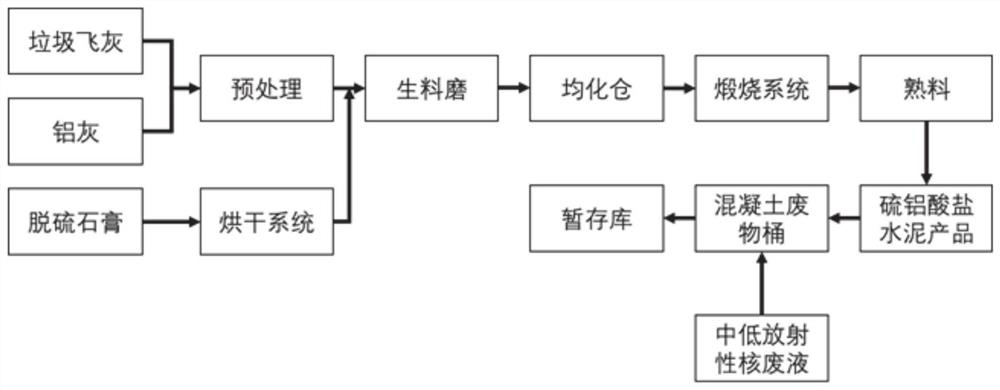

[0027] In a second aspect, the present invention provides a method for preparing the solid waste-based sulphoaluminate cement solidified base material of the low-medium radioactive nuclear waste, comprising the following steps:

[0028] After the garbage fly ash and aluminum ash are mixed and pretreated, they are mixed with the dried desulfurized gypsum in proportion, and the mass ratio of garbage fly ash, aluminum ash, and desulfurized gypsum is 25-45:27-33:20-40;

[0029] Grinding the mixed raw material until the particle size of the material after grinding is less than 8 μm;

[0030] It is obtained by calcining the mixed raw meal after grinding.

[0031] In some embodiments, the mixed pretreatment method of garbage fly ash and aluminum ash is as follows: After mixing garbage fly ash and aluminum ash in proportion, perform high-temperature heating pretreatment, the heating temperature is 900-950°C, and the heating time is 20- 40min. The heat treatment temperature of 900-95...

Embodiment 1

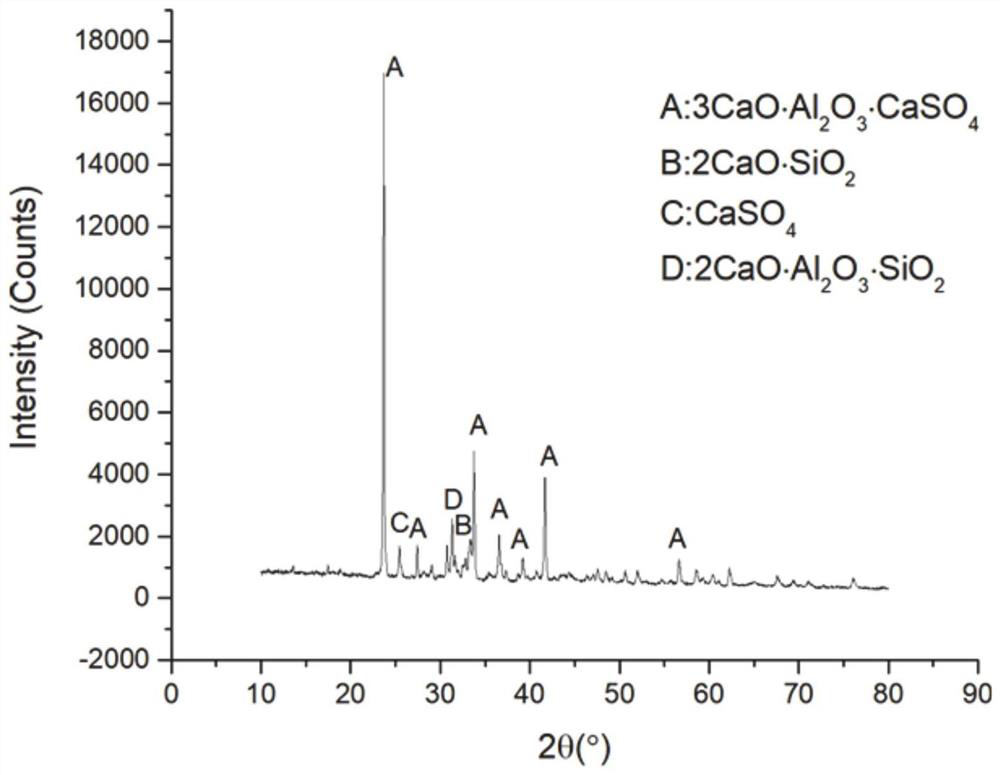

[0039] Such as figure 1 As shown, the garbage fly ash, aluminum ash, and desulfurized gypsum were pretreated at 34.1, 28.2, and 37.7 parts by mass, respectively, and then put into the raw meal mill for grinding, and the raw meal obtained was passed into the homogenization tank for homogenization , and then transported to a calcination device for calcination, the calcination temperature is 1250° C., and the calcination time is 60 minutes to obtain a sulphoaluminate solidified substrate.

[0040] The compressive strength of cement slurry (the mass ratio of sulfoaluminate solidified base material to water is 7:3) at 3 days and 28 days is 68.5Mpa and 100.6Mpa, respectively.

[0041] 0.750kg of solid waste-based sulfoaluminate cement solidified substrate, 0.220kg of sand and Cs waste liquid concentrate (the concentration of Cs waste liquid concentrate is boron content 30g / L, total salt content 100g / L, Cs content 1wt %) 0.320L mixing and stirring, curing and molding.

[0042] The ...

Embodiment 2

[0046] Garbage fly ash, aluminum ash, and desulfurized gypsum are pretreated according to the following mass parts: 32.2 parts, 30.2 parts and 37.6 parts respectively, and then put into the raw meal mill for grinding. The obtained raw meal is passed into the homogenization tank for homogenization, and then transported Calcination in a calcination device with a calcination temperature of 1270° C. and a calcination time of 60 minutes to obtain a sulfoaluminate solidified substrate.

[0047] The compressive strength of cement slurry (the mass ratio of sulfoaluminate solidified base material to water is 7:3) at 3 days and 28 days is 71.2Mpa and 105.9Mpa, respectively.

[0048] Solid waste-based sulfoaluminate cement solidified substrate 0.750kg, sand 0.220kg and Cs waste liquid concentrate (the concentration of the Cs waste liquid concentrate is boron content 35g / L, total salt content 100g / L, Cs content 1.0 wt%) 0.320L, mixed and stirred, solidified and formed.

[0049] The Cs le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com