Early strength compound admixture for full mill tailing pasty fluid cemented filling material

A technology of cemented filling materials and full tailings, which is applied in the field of mine filling, can solve the problems of low compressive strength, achieve low cost, improve stability, and facilitate industrial production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

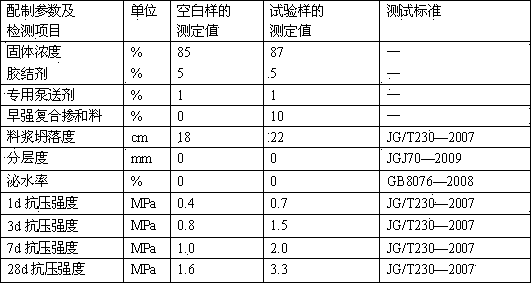

Embodiment 1

[0019] An early-strength composite admixture for full tailings paste cemented filling materials, which is made by mixing desulfurized gypsum from power plants, quicklime powder, and ultrafine limestone powder;

[0020] The desulfurization gypsum of the power plant has a square hole sieve with a fineness of 80 μm and a sieve residue of less than 10%, and a moisture content of less than 2%;

[0021] The quicklime powder has a fineness of less than 10% through a square hole sieve with a fineness of 80 μm, and a moisture content of less than 2%;

[0022] The ultrafine limestone powder has a maximum particle size of less than 20 μm and an average particle size of 5-6 μm.

[0023] The early-strength composite admixture used for the cemented filling material of the whole tailing sand body, each raw material component is counted in parts by mass, power plant desulfurization gypsum: quicklime powder: superfine limestone powder=10:5:85.

[0024] After the raw materials of each componen...

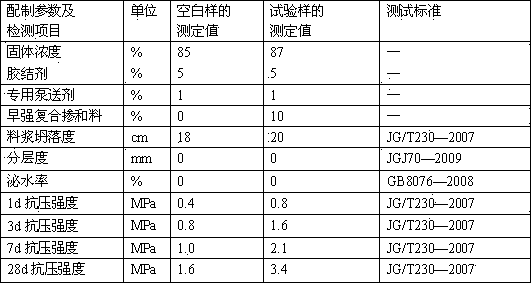

Embodiment 2

[0028] An early-strength composite admixture for full tailings paste cemented filling materials, which is made by mixing desulfurized gypsum, slaked lime powder, and ultrafine limestone powder;

[0029] The desulfurization gypsum of the power plant has a square hole sieve with a fineness of 80 μm and a sieve residue of less than 10%, and a moisture content of less than 2%;

[0030] The slaked lime powder has a fineness of less than 10% on a square hole sieve with a fineness of 80 μm, and a moisture content of less than 2%;

[0031] The ultrafine limestone powder has a maximum particle size of less than 20 μm and an average particle size of 5-6 μm.

[0032] The early-strength composite admixture used for the cemented filling material of the whole tailing sand body, each raw material component is counted in parts by mass, power plant desulfurization gypsum: slaked lime powder: superfine limestone powder = 15: 7: 78.

[0033] After the raw materials of each component are accurat...

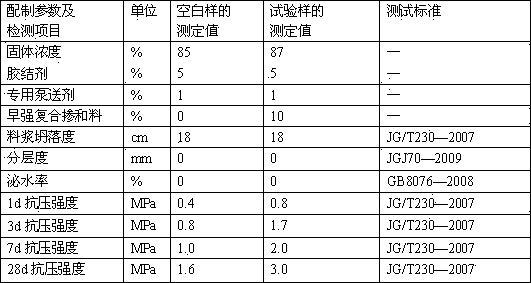

Embodiment 3

[0037] An early-strength composite admixture for full tailings paste cemented filling materials, which is made of natural gypsum, slaked lime powder, and superfine limestone powder;

[0038] The natural gypsum has a fineness of less than 10% through a square hole sieve with a fineness of 80 μm, and a moisture content of less than 2%;

[0039] The slaked lime powder has a fineness of less than 10% on a square hole sieve with a fineness of 80 μm, and a moisture content of less than 2%;

[0040] The ultrafine limestone powder has a maximum particle size of less than 20 μm and an average particle size of 5-6 μm.

[0041]The early-strength composite admixture used for the cemented filling material of the whole tailing sand body, each raw material component is calculated in parts by mass, natural gypsum: slaked lime powder: superfine limestone powder = 20: 10: 70.

[0042] After the raw materials of each component are accurately measured and ground to the specified fineness, they a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com