Method for preparing concrete enhancer by utilizing nickel slag

A concrete reinforcing agent and reinforcing agent technology, which is applied in the field of building materials, can solve the problems of reduced concrete strength, high price, and reduced concrete durability in the later stage, and achieve the improvement of later compressive strength and early compressive strength. The formula and simplicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) The ratio of the reinforcing agent is (percentage by weight): nickel slag / formic acid=1:1;

[0020] (2) The concentration of formic acid is 10%;

[0021] (3) Reaction conditions: temperature is 20°C; time is 24h.

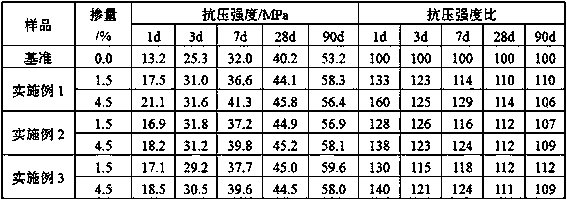

[0022] Add the above prepared reinforcing agents to concrete, and the 1d, 3d, 7d, 28d and 90d compressive strength increase effects are shown in Table 1.

Embodiment 2

[0024] (1) The ratio of reinforcing agent is (percentage by weight): nickel slag / formic acid=1.2:1;

[0025] (2) The concentration of formic acid is 15%;

[0026] (3) Reaction conditions: temperature is 40°C; time is 10h.

[0027] Add the above prepared reinforcing agents to concrete, and the 1d, 3d, 7d, 28d and 90d compressive strength increase effects are shown in Table 1. Example 3

Embodiment 3

[0028] (1) The ratio of reinforcing agent is (weight percent): nickel slag / formic acid=1.4:1;

[0029] (2) The concentration of formic acid is 10%;

[0030] (3) Reaction conditions: temperature is 30°C; time is 12h.

[0031] Add the above prepared reinforcing agents to concrete, and the 1d, 3d, 7d, 28d and 90d compressive strength increase effects are shown in Table 1.

[0032] Table 1 Contrast of concrete compressive strength before and after using the present invention

[0033]

[0034] Note: The concrete mix ratio is W / C ratio of 0.60, and the dosage of 42.5 ordinary silicate cement is 400kg / m 3 , The sand rate is 35%.

[0035] As can be seen from Table 1, the reinforcing agent product of the present invention not only has a significant strengthening effect on the concrete 1d-7d compressive strength, and the 28d-90d compressive strength will not shrink back, but still has a greater strengthening effect. Among them, the compressive strength of concrete 1d, 3d, 7d, 28d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com