Preparation method of phosphogypsum slag-based cement

A phosphogypsum and slag technology, applied in the field of preparation of phosphogypsum slag-based cement, can solve the problems of long setting time, low early strength, easy carbonization, etc., and achieve the effects of short setting time, increased compressive strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

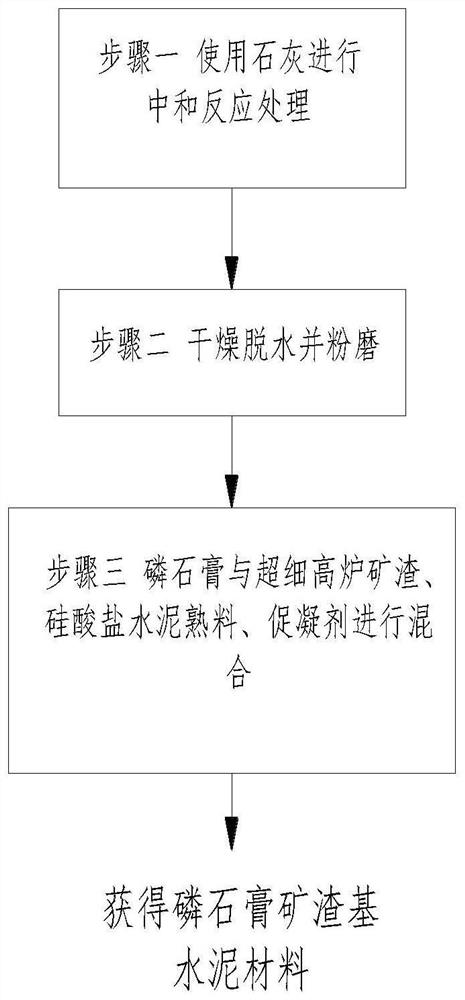

[0028] Example: see figure 1 , a preparation method of phosphogypsum slag-based cement, the method steps are as follows,

[0029] Step 1, use lime to carry out neutralization reaction treatment on phosphogypsum, mix phosphogypsum with a certain proportion of lime evenly, make it fully neutralize, remove impurities soluble phosphorus and soluble fluorine, the lime is quicklime or slaked lime, its The mixing ratio is 3%-5% of the mass of phosphogypsum;

[0030] Step 2. Place the prepared phosphogypsum in a blast drying oven, dry it to constant weight at 105°C to remove free water, and then grind it in a horizontal ball mill until the specific surface area is 400m 2 / kg or so;

[0031] By modifying the phosphogypsum through the above steps, the quality of the phosphogypsum is improved, and the adverse effects of impurities in the phosphogypsum on the performance of the phosphogypsum slag-based cement are reduced.

[0032] Step 3, combining the prepared phosphogypsum with ultra...

example 1

[0042] Example 1: the unslaked lime that mixes 4% of phosphogypsum quality carries out neutralization reaction treatment to phosphogypsum and makes pretreated phosphogypsum, and its raw material components are calculated by mass percentage:

[0043] Phosphogypsum after pretreatment: 15%;

[0044] The specific surface area is 800m 2 / kg superfine blast furnace slag: 80%;

[0045] The specific surface area is 350m 2 42.5 Portland cement clinker / kg: 4%;

[0046] Aluminate cement: 1%;

[0047] The above-mentioned raw materials are taken and thoroughly mixed uniformly to prepare phosphogypsum slag-based cement. The water-to-cement ratio is 0.4. After testing, the phosphogypsum slag-based cement prepared by the present invention has a 3d compressive strength of 20.1MPa, a 28d compressive strength of 58.6MPa, and a 90d compressive strength of 64.8MPa. The initial setting time is 102min, and the final setting The time is 260min.

example 2

[0048] Example 2: the quick lime mixed with 4% of the phosphogypsum quality is carried out to the phosphogypsum after the neutralization reaction treatment to make the pretreated phosphogypsum, and its raw material components are calculated by mass percentage:

[0049] Phosphogypsum after pretreatment: 15%;

[0050] The specific surface area is 1000m 2 / kg superfine blast furnace slag: 80%;

[0051] The specific surface area is 400m 2 42.5 Portland cement clinker / kg: 4%;

[0052] Aluminate cement: 1%;

[0053] The above-mentioned raw materials are taken and thoroughly mixed uniformly to prepare phosphogypsum slag-based cement. Using water-binder ratio of 0.4, after testing, the phosphogypsum slag-based cement prepared by the present invention has a 3d compressive strength of 25.3MPa, a 28d compressive strength of 62.6MPa, a 90d compressive strength of 70.5MPa, an initial setting time of 90min, and a final setting The time is 240min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com