Concrete and preparation method thereof

A concrete and mixture technology, applied in the field of concrete and its preparation, can solve problems affecting concrete compressive strength, concrete cracks, etc., and achieve the effects of improving work performance, reducing cracks, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

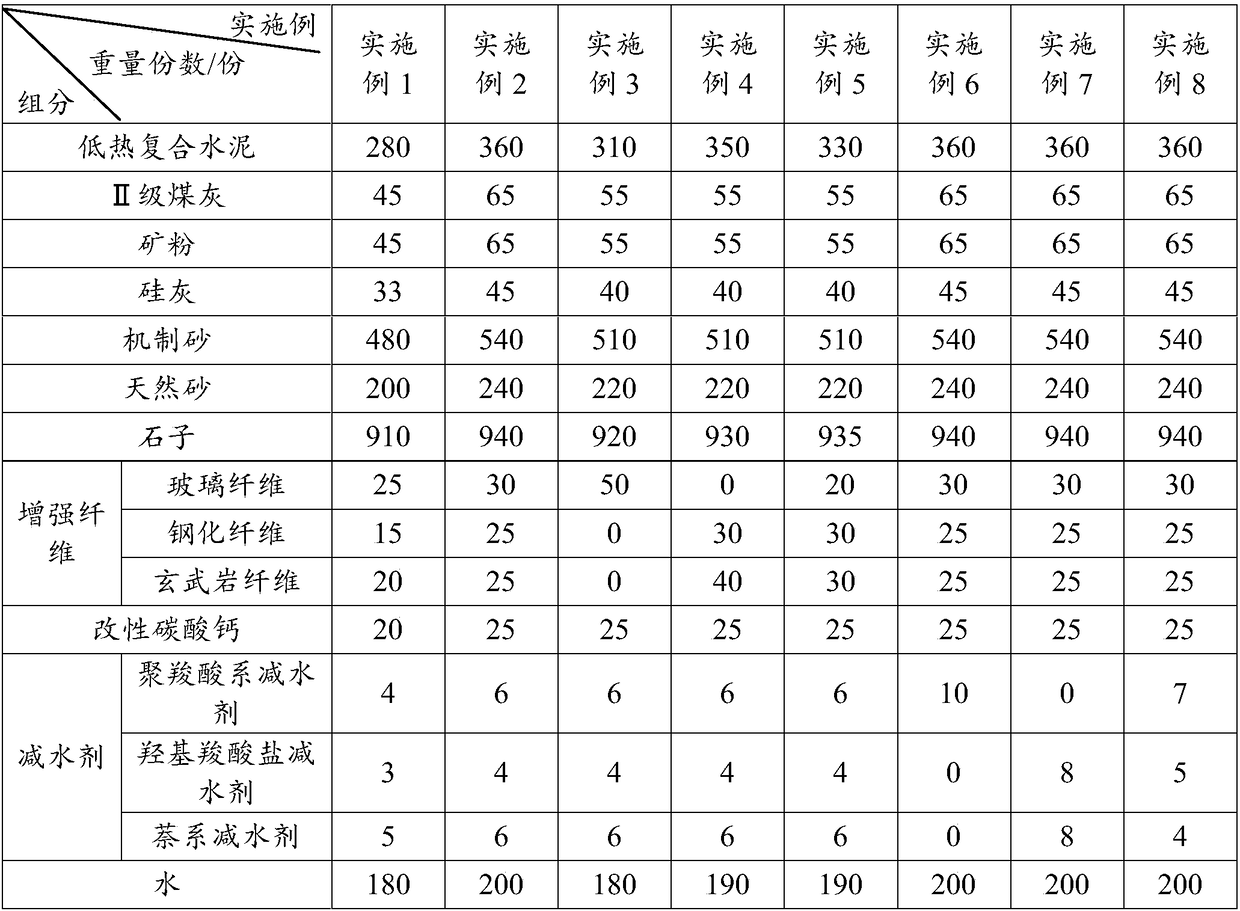

[0066] Embodiment 1: A kind of concrete, the raw material component that comprises and corresponding weight parts thereof are as shown in Table 1, and obtain through the following steps preparation:

[0067] Step 1: Weigh silica fume and natural sand according to the ratio of parts by weight, and mix them with water accounting for 60% of the total weight and parts ratio of silica fume and natural sand, then add modified calcium carbonate, and the stirring speed is 200r / min , stirred for 15 minutes, and mixed uniformly to obtain the first mixture;

[0068] Step 2, take machine-made sand, gravel, glass fiber, tempered fiber, basalt fiber according to the number of parts by weight, and then add it to the first mixture obtained by step A, stir at a speed of 500r / min, stir for 15min, and mix evenly to obtain the second mixture;

[0069] Step 3: Weigh low-heat composite cement, Class II coal ash, mineral powder, polycarboxylate water reducer, hydroxycarboxylate water reducer, napht...

Embodiment 2-8

[0077] Embodiment 2-8: A kind of concrete, the difference from Embodiment 1 lies in that the raw material components and their corresponding parts by weight are shown in Table 1.

Embodiment 9

[0078] Embodiment 9: A kind of concrete, the difference from Example 1 is that in the step 3 of the preparation method, the low-heat composite cement is composed of 85wt.% low-heat portland cement clinker and 6wt.% sulfur aluminum Composition of acid cement clinker, 9wt.% gypsum and 5wt.% magnesium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com