High-temperature silt stabilizing agent and preparation method thereof

A high-performance, stabilizer technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of limited industrial waste consumption, environmental pollution hazards, land occupation, etc., and achieve faster curing speed, shorter curing time, and lower project cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

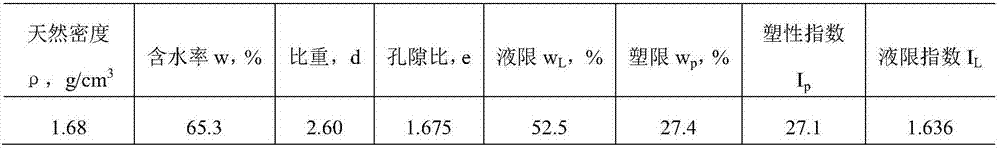

Method used

Image

Examples

Embodiment 1

[0062] The high-performance sludge stabilizer provided by this embodiment is composed of the following components in mass percentage:

[0063] Blast furnace slag powder 44%

[0064] Fly Ash 26%

[0065] Quicklime 11%

[0066] Gelling agent 6%

[0067] Phosphogypsum 5%

[0068] Flocculant 3%

[0069] Stimulant 3%

[0070] Enhancer 2%.

[0071]Among the components of high-performance sludge stabilizer:

[0072] Blast furnace slag powder should meet the technical requirements of the standard "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" GB / T8046, and the specific surface area of blast furnace slag powder should not be less than 500m 2 / kg, density not less than 2.8g / cm 3 , 7d activity index is not less than 95%, chloride ion content is not more than 0.06%, loss on ignition is not more than 3%.

[0073] Fly ash should meet the technical requirements of the standard "Fly Ash Used in Cement and Concrete" GB / T1596. The fineness of fly ash should not ex...

Embodiment 2

[0086] The high-performance sludge stabilizer provided by this embodiment is composed of the following components in mass percentage:

[0087] Blast furnace slag powder 48%

[0088] Fly Ash 18%

[0089] Quicklime 13%

[0090] Gelling agent 8%

[0091] Phosphogypsum 6%

[0092] Flocculant 2%

[0093] Stimulant 3%

[0094] Enhancer 2%.

[0095] Among the components of high-performance sludge stabilizer:

[0096] Blast furnace slag powder should meet the technical requirements of the standard "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" GB / T8046, and the specific surface area of blast furnace slag powder should not be less than 500m 2 / kg, density not less than 2.8g / cm 3 , 7d activity index is not less than 95%, chloride ion content is not more than 0.06%, loss on ignition is not more than 3%.

[0097] Fly ash should meet the technical requirements of the standard "Fly Ash Used in Cement and Concrete" GB / T1596. The fineness of fly ash should not e...

Embodiment 3

[0106] The high-performance sludge stabilizer provided by this embodiment is composed of the following components in mass percentage:

[0107] Blast furnace slag powder 42%

[0108] Fly Ash 24%

[0109] Quicklime 12%

[0110] Gelling agent 7%

[0111] Phosphogypsum 8%

[0112] Flocculant 3%

[0113] Stimulator 2%

[0114] Enhancer 2%.

[0115] Among the components of high-performance sludge stabilizer:

[0116] Blast furnace slag powder should meet the technical requirements of the standard "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" GB / T8046, and the specific surface area of blast furnace slag powder should not be less than 500m 2 / kg, density not less than 2.8g / cm 3 , 7d activity index is not less than 95%, chloride ion content is not more than 0.06%, loss on ignition is not more than 3%.

[0117] Fly ash should meet the technical requirements of the standard "Fly Ash Used in Cement and Concrete" GB / T1596. The fineness of fly ash should not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com