Ground surface course based on phosphorus and magnesium material and construction process thereof

A construction process, phosphorus-magnesium technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of hollowing, anti-skid, wear resistance that does not meet engineering design requirements, and cracks that cannot be eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

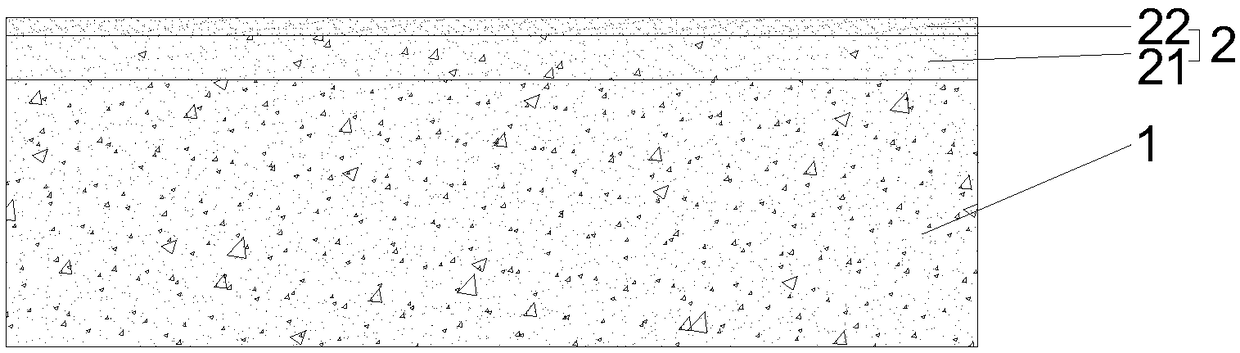

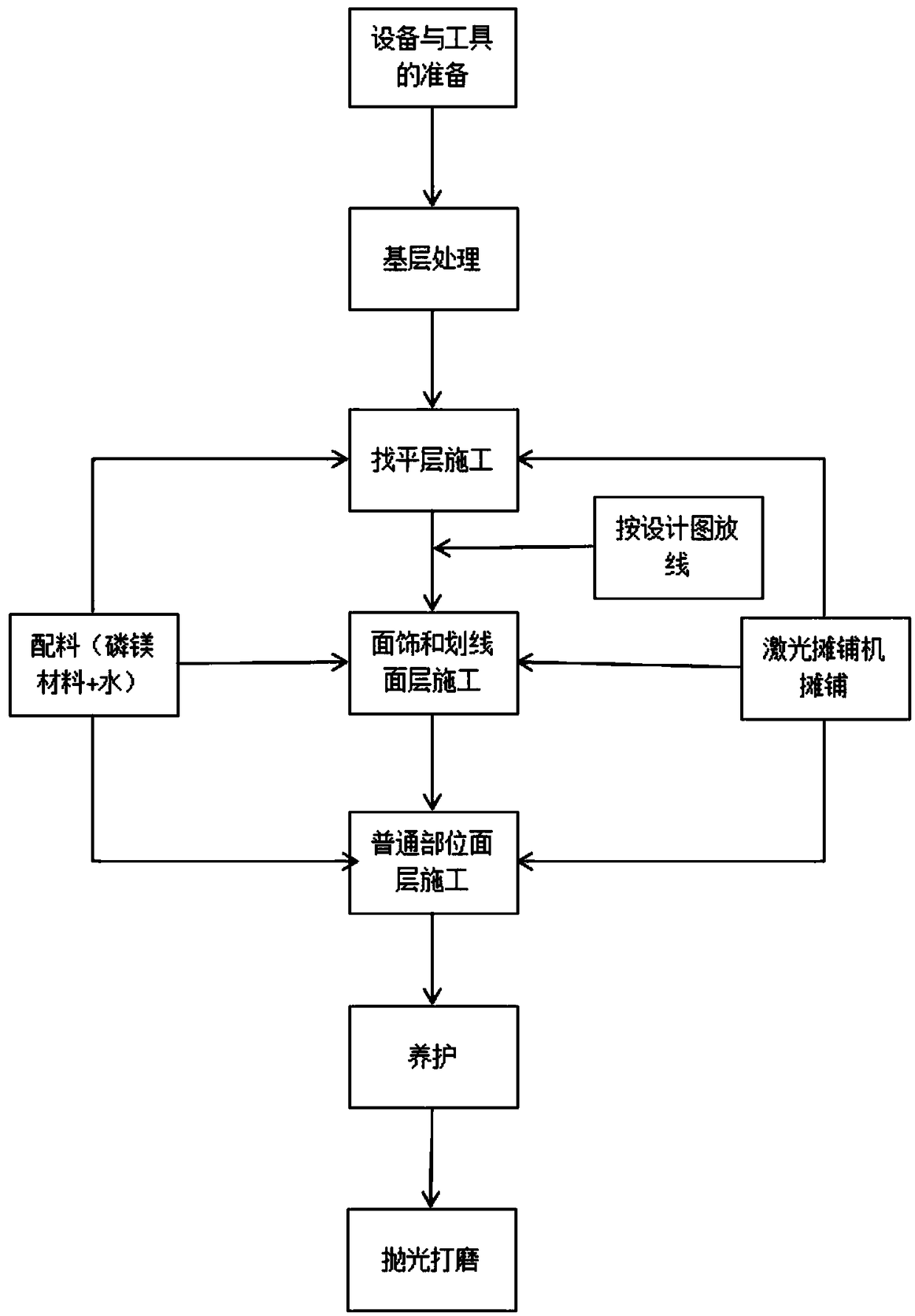

[0110] A ground surface layer based on phosphorus-magnesium material, which has a two-layer structure, has a layer of phosphorus-magnesium leveling layer, and a layer of phosphorus-magnesium surface layer, and is constructed by the following method:

[0111] (1) Basic treatment:

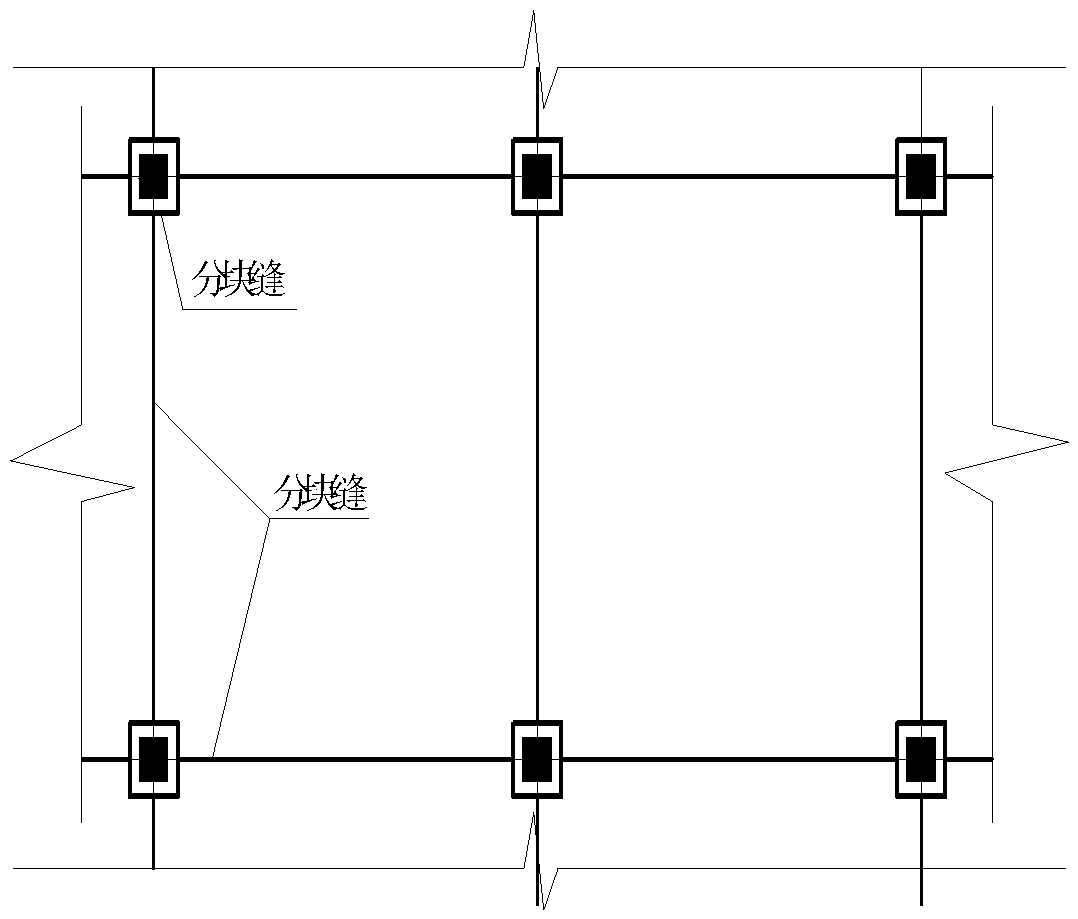

[0112] Use zonal treatment to remove accumulated water, check the leakage of the bottom plate, find out the structural gaps, mark them with ink lines, and cut the leaking parts into a "V" shape with a depth of 5cm. ) is tightly sealed, check after drying, if there is no leakage, then use phosphorus and magnesium materials to seal tightly, and the surface of fine stone concrete shall not exceed 2cm of the structural slab surface; after the leakage and sealing of the bottom slab are completed, polish and clean the surface of the bottom slab Clean (make sure there is no laitance and garbage on the surface) until the structural concrete is completely exposed, and the parts that cannot be polished by the ...

Embodiment 2

[0141] A ground surface layer based on phosphorus-magnesium material has a two-layer structure, with one layer of phosphorus-magnesium leveling layer and one layer of phosphorus-magnesium surface layer. During the construction process, the phosphorus-magnesium material and water are mixed in a ratio of 1:0.08; After the initial setting of the surface of the magnesium material mortar, cover the surface of the phosphorus-magnesium material mortar with plastic cling film, and seal and cure for 1 hour; after sealing and curing for 1 hour, the compressive strength of the surface layer reaches more than 20MPa, then polish and polish, and the dust residue after grinding is sucked off with a vacuum cleaner , other steps are identical with embodiment 1.

[0142] The phosphorus-magnesium material is a mixed phosphorus-magnesium material A.

Embodiment 3

[0144] A ground surface layer based on phosphorus-magnesium material has a two-layer structure, with one layer of phosphorus-magnesium leveling layer and one layer of phosphorus-magnesium surface layer. During the construction process, the phosphorus-magnesium material and water are mixed in a ratio of 1:0.15; After the initial setting of the surface of the magnesium material mortar, cover the surface of the phosphorous magnesium material mortar with plastic cling film, and seal and cure for 2 hours; after sealing and curing for 2 hours, the compressive strength of the surface layer reaches more than 20MPa, then polish and polish, and the dust residue after grinding is sucked off with a vacuum cleaner Other steps are identical with embodiment 1.

[0145] The phosphorus-magnesium material is a mixed phosphorus-magnesium material A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com