Calcium sulfate composite raised flooring

A raised floor, calcium sulfate technology, applied in local raised floors, floors, buildings, etc., can solve problems such as difficulty in leveling, and achieve the effects of preventing corners from falling off, increasing elasticity and service life, and being easy to transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

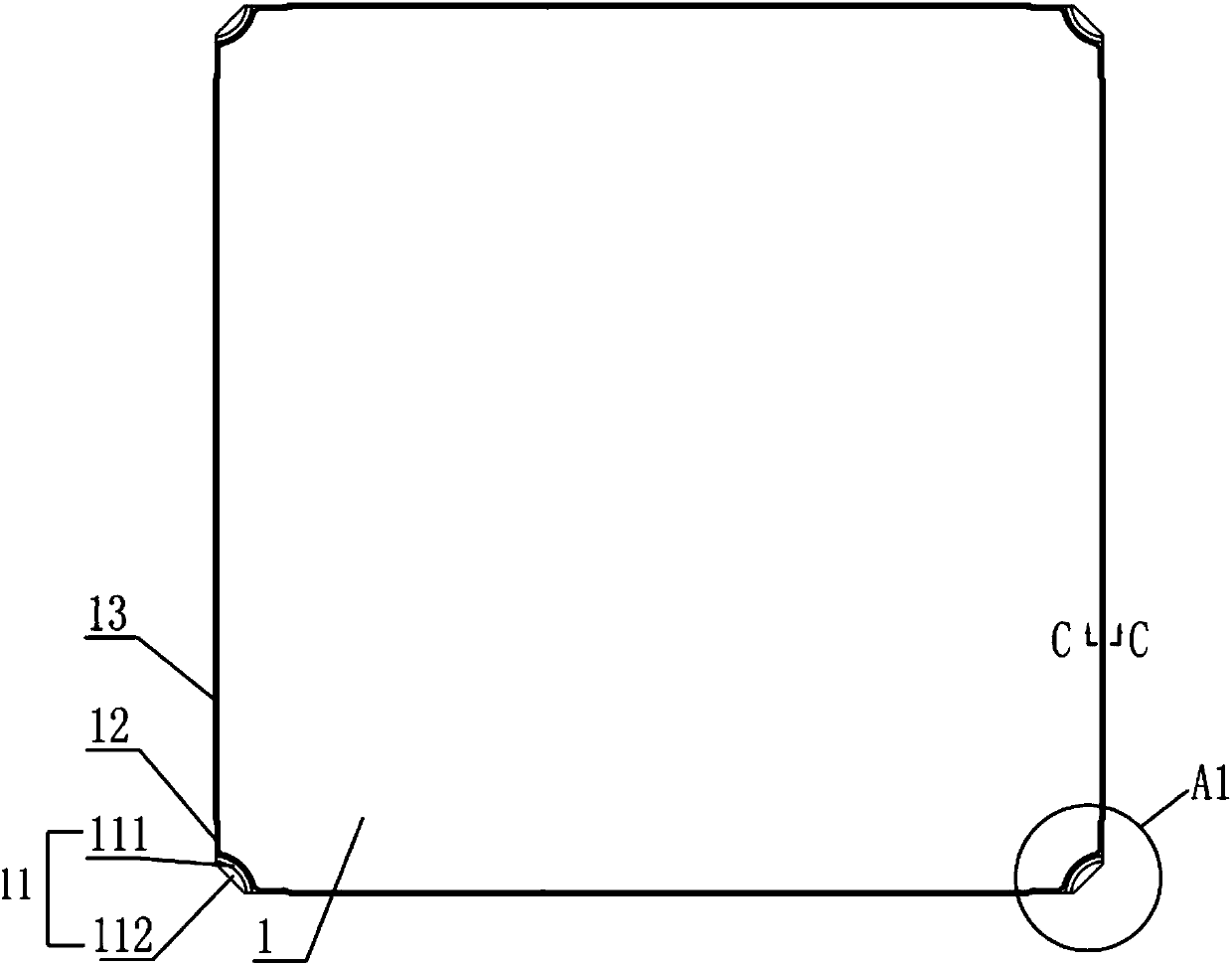

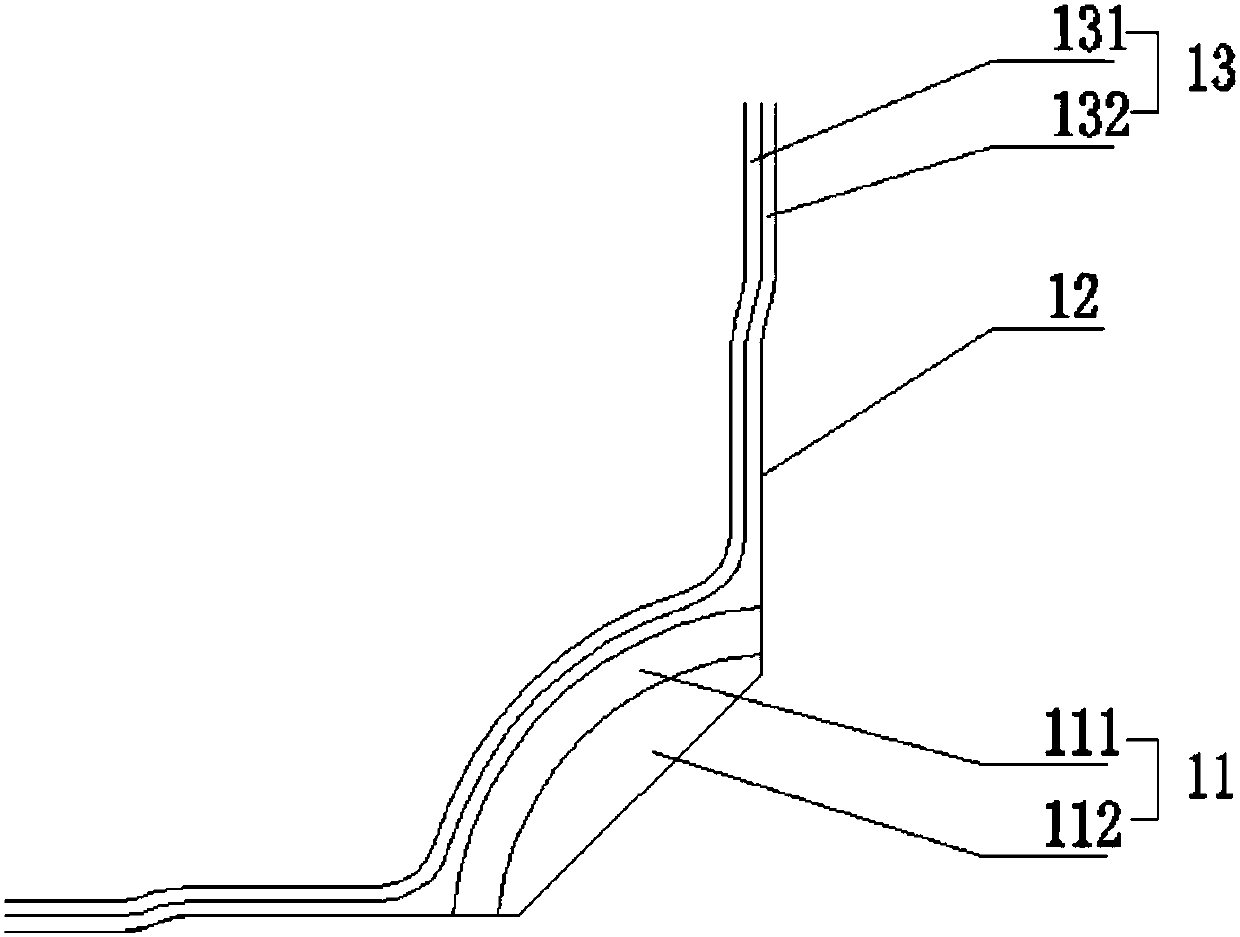

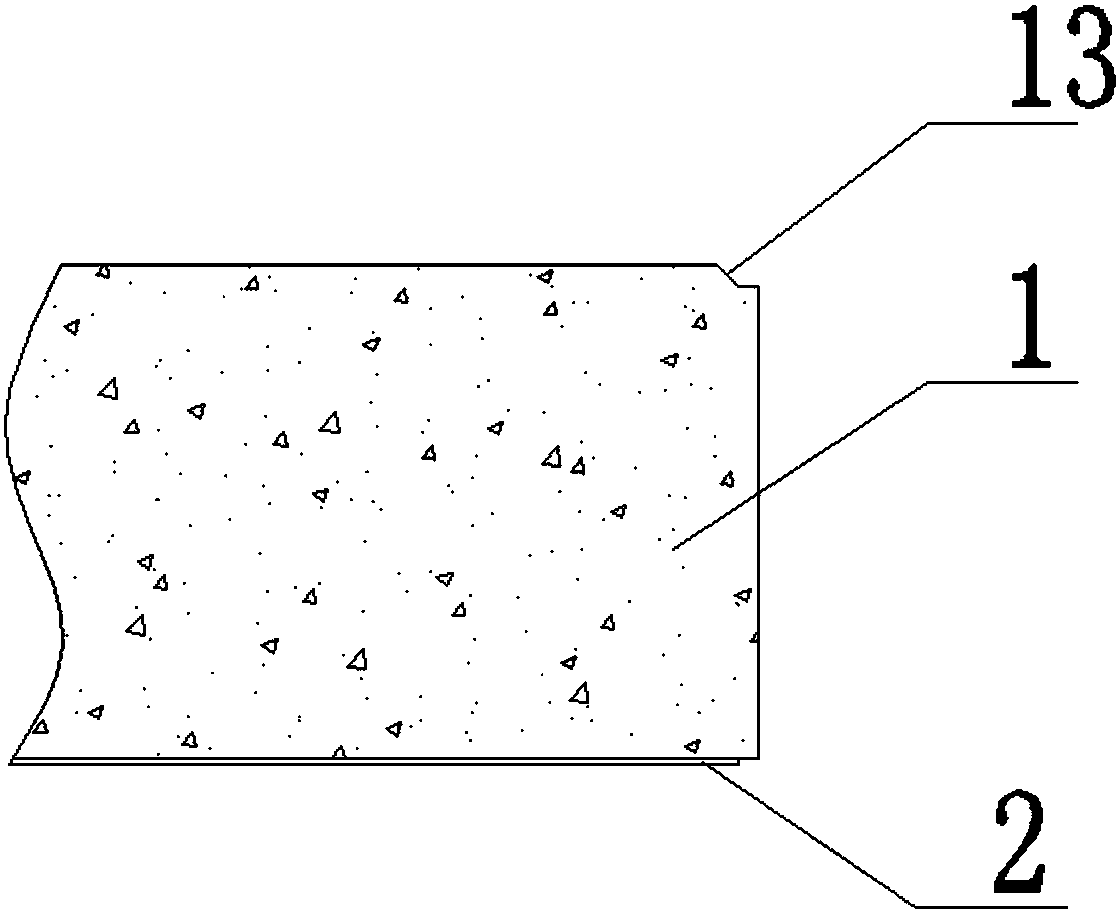

[0044] Such as Figure 1-7 As shown, a raised floor is composed of a base material 1 and a support plate 2 installed at the bottom of the base material 1. The base material 1 is integrally formed by mold pouring and pressure. The base material 1 is a square structure with There is a sinking arc-shaped slope 111 and a sinking bevel platform 112. The sinking bevel platform 112 is connected with the bottom of the sinking circular-arc slope 1 to form a step A11. Preferably, the slope of the sinking bevel platform 112 and the corresponding The included angle between the sides of the adjacent two substrates is 135°, the central angle of the sunken arc-shaped inclined surface 111 is 45°, and its arc is a 1 / 4 arc; the periphery of the support plate 2 does not exceed the periphery of the substrate 1; Four raised floors laid in adjacent positions form a sinkhole in the middle of the four adjacent steps A, and four adjacent sinking arc-shaped inclined surfaces 111 are combined to form a ...

Embodiment 2

[0049] On the basis of Example 1, a circle of sinking slope C131 and a sinking platform C132 connected to the bottom of the sinking slope C are provided through the edge of the upper surface of the substrate 1, and the sinking slope C and the sinking platform C form a step C13. Step C is located above step A to form a double-layer step structure, such as Figure 1-5 shown. Preferably, the circular arc formed by the step C at the four corners of the base material and the circular arc formed by the step A are concentric circular arcs, which is convenient for processing and beautiful. The setting of step C reduces the sharp edges and corners of the floor substrate, effectively reduces the probability of falling blocks, missing corners, and bruises around the substrate, facilitates production, transportation, installation and use, and facilitates the control of adverse effects of uneven floors on installation. Increases the speed of floor installation.

Embodiment 3

[0051] On the basis of Example 2, two opposite sides of the base material 1 are respectively provided with rectangular notches A14, such as Figure 8-11 As shown, the three sides of the gap A are provided with a sinking slope D141 and a sinking platform D142 connected to the bottom edge of the sinking slope D. The sinking slope D and the sinking platform D form a step D143, and the step D is formed below the step C. Double-layer step structure; the two opposite sides of the support plate 2 below the notch A are provided with a rectangular notch A'23, the notch A' matches the shape of the notch A, and does not exceed the edge of the notch A, such as Figure 12 shown.

[0052] The rectangular gaps of two adjacent raised floors are spliced to form a square structure. The cube structure can be placed with a ground socket, and can also be used as an outlet for wiring, and an outgoing line cover is placed, and the ground socket or the outgoing line cover is flush with the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com