Fabricated building sleeve connecting grouting material based on phosphorus and magnesium materials and construction method of grouting material

A sleeve connection and grouting material technology, which is applied in the direction of construction, building components, building structures, etc., to achieve the effects of improving work performance, reducing consumption, increasing bulk density and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

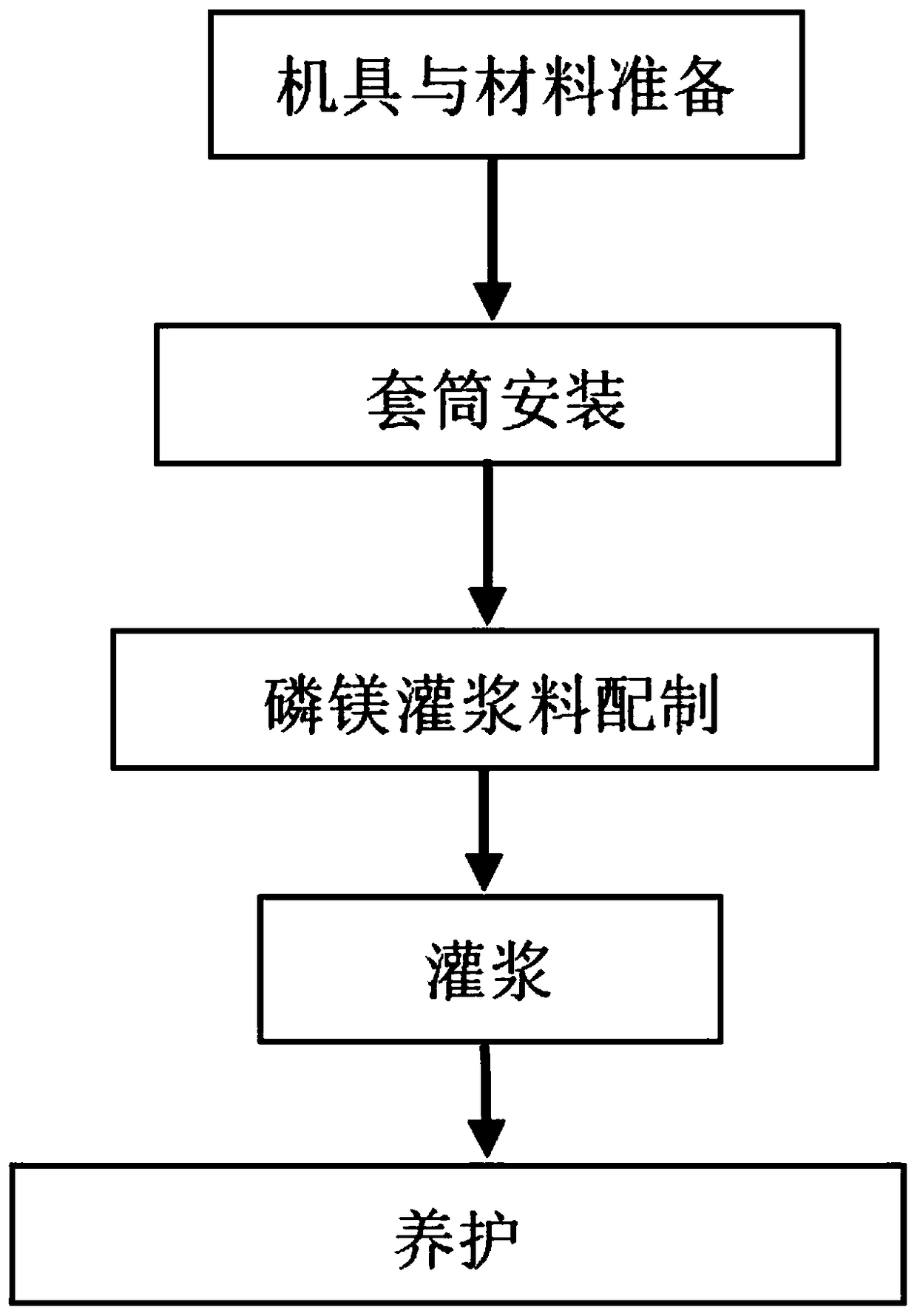

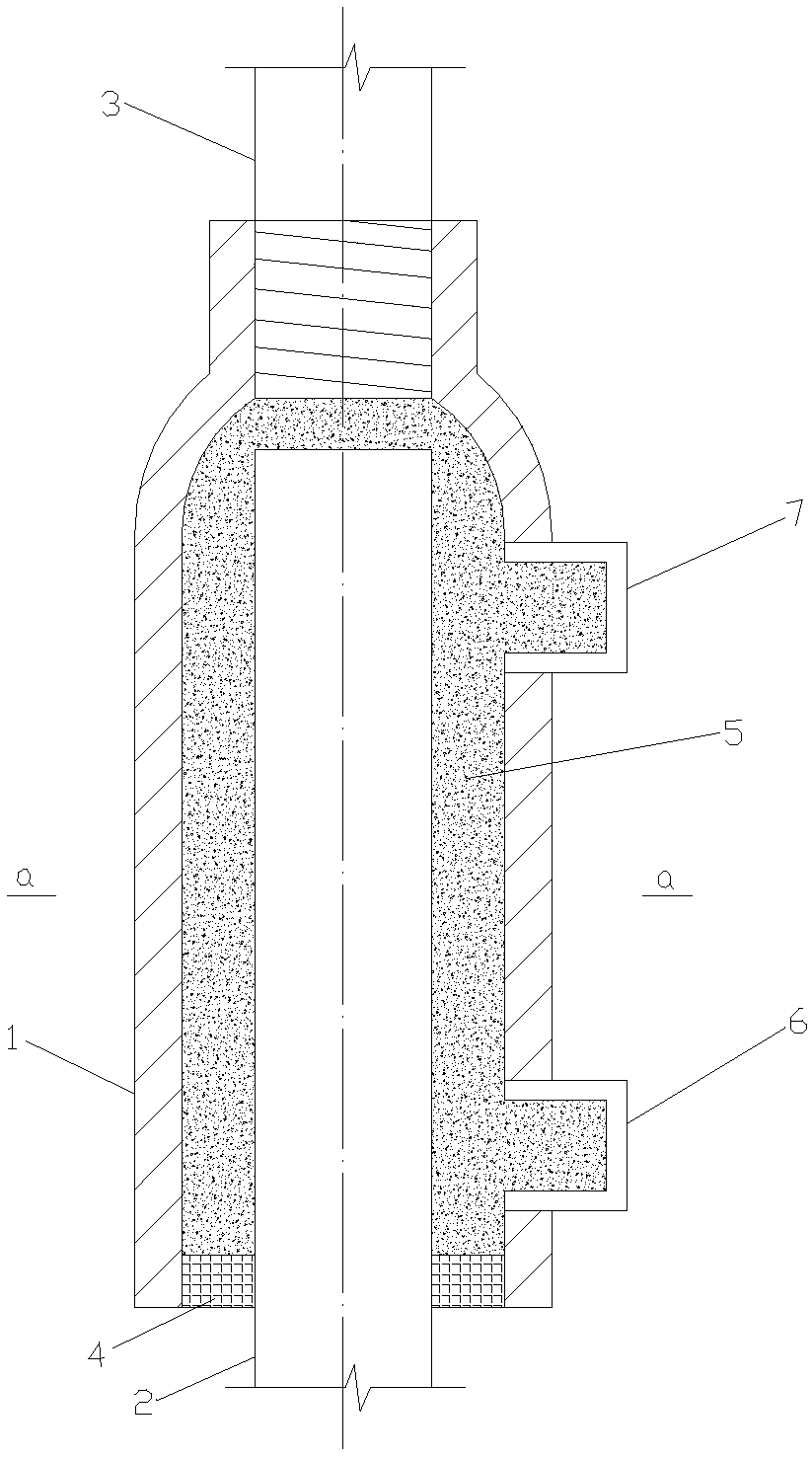

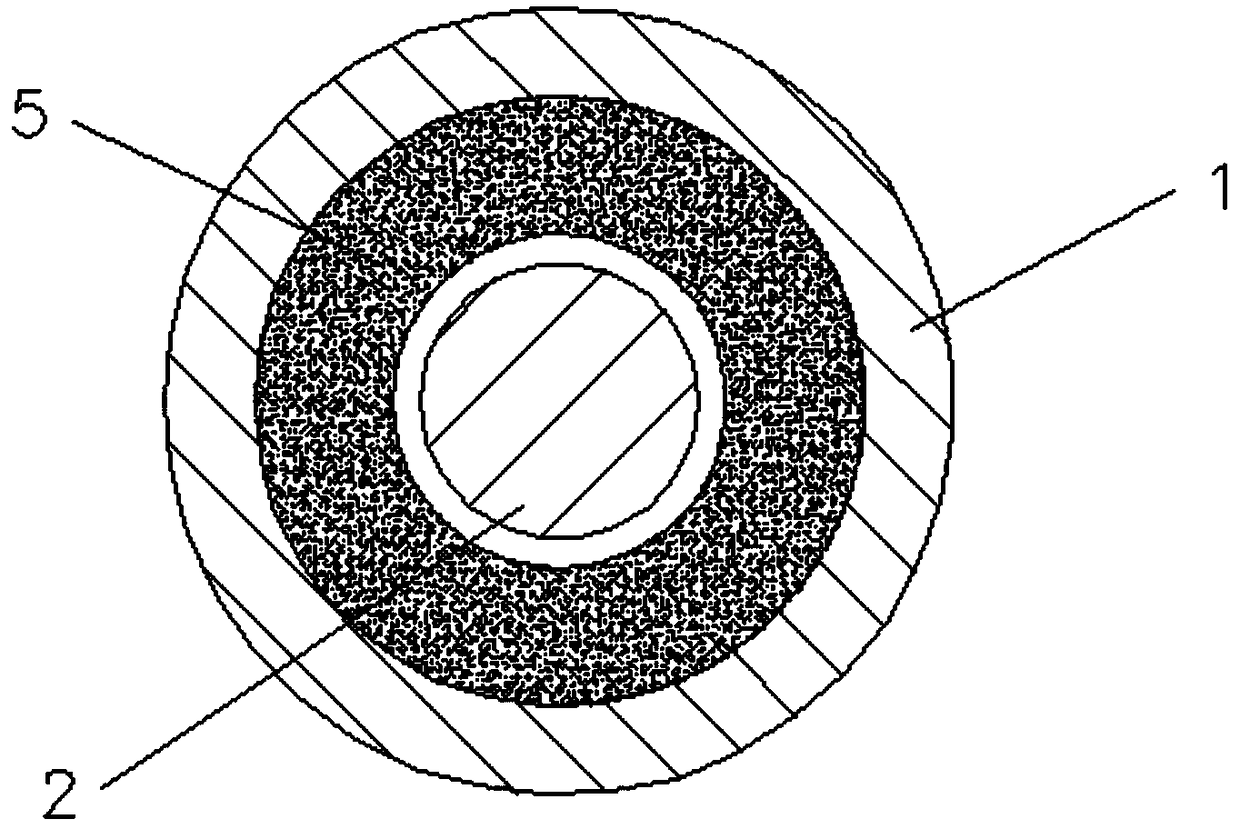

Method used

Image

Examples

Embodiment 1

[0046] A prefabricated construction sleeve connection grouting material based on phosphorus and magnesium materials is prepared from the following raw materials in parts by weight: 80 parts of magnesium phosphate cement, 3 parts of admixture, 10 parts of admixture, and 1 part of aggregate.

[0047] Further, the magnesium phosphate cement is a mixture of dead-burned magnesia and monoammonium phosphate, and the ratio of dead-burned magnesia and monoammonium phosphate is 4:1; It is obtained by grinding after calcining, its magnesium oxide content is 88%, and its fineness is 60 mesh; the fineness of the monoammonium phosphate is 60 mesh, and its nutrient content is 72%; The mixture of water reducer and water reducer; the defoamer is a silicone powder defoamer; The fineness is 60 mesh; the admixture is a mixture of fly ash and metakaolin; the fineness of the fly ash is 300 mesh; the metakaolin has been calcined above 800°C, and the fineness is 800 mesh; The above-mentioned aggrega...

Embodiment 2

[0055] A prefabricated construction sleeve connection grouting material based on phosphorus and magnesium materials is made of the following raw materials in parts by weight: 120 parts of magnesium phosphate cement, 16 parts of admixture, 25 parts of admixture, and 130 parts of aggregate.

[0056] Further, the magnesium phosphate cement is a mixture of dead-burned magnesia and monoammonium phosphate, and the ratio of dead-burned magnesia and monoammonium phosphate is 1:1; It is obtained by grinding after calcining, its magnesium oxide content is 95%, and its fineness is 400 mesh; the fineness of the monoammonium phosphate is 400 mesh, and its nutrient content is 60%; The mixture of water reducer and water reducer; the defoamer is a silicone powder defoamer; the retarder is borax, and the purity of the retarder is not less than 95%, fine The fineness is 400 mesh; the admixture is a mixture of fly ash and metakaolin; the fineness of the fly ash is 2000 mesh; the metakaolin has b...

Embodiment 3

[0064] A prefabricated building sleeve connection grouting material based on phosphorus magnesium material is made of the following raw materials in parts by weight: 90 parts of magnesium phosphate cement, 6 parts of admixture, 13 parts of admixture, and 10 parts of aggregate.

[0065] Further, the magnesium phosphate cement is a mixture of dead-burned magnesia and monoammonium phosphate, and the ratio of dead-burned magnesia and monoammonium phosphate is 3.5:1; It is obtained by grinding after calcining, its magnesium oxide content is 89%, and its fineness is 100 mesh; the fineness of the monoammonium phosphate is 100 mesh, and its nutrient content is 60%; The mixture of water reducer and water reducer; the defoamer is a silicone powder defoamer; the retarder is borax, and the purity of the retarder is not less than 95%, fine The fineness is 100 mesh; the admixture is a mixture of fly ash and metakaolin; the fineness of the fly ash is 400 mesh; the metakaolin has been calcine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com