Method for improving whiteness of titanium dioxide by adjusting granularity

A technology of titanium dioxide and whiteness, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem of low whiteness of titanium dioxide products, achieve good hue and gloss, good dehydration and desulfurization effects, and stable internal changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

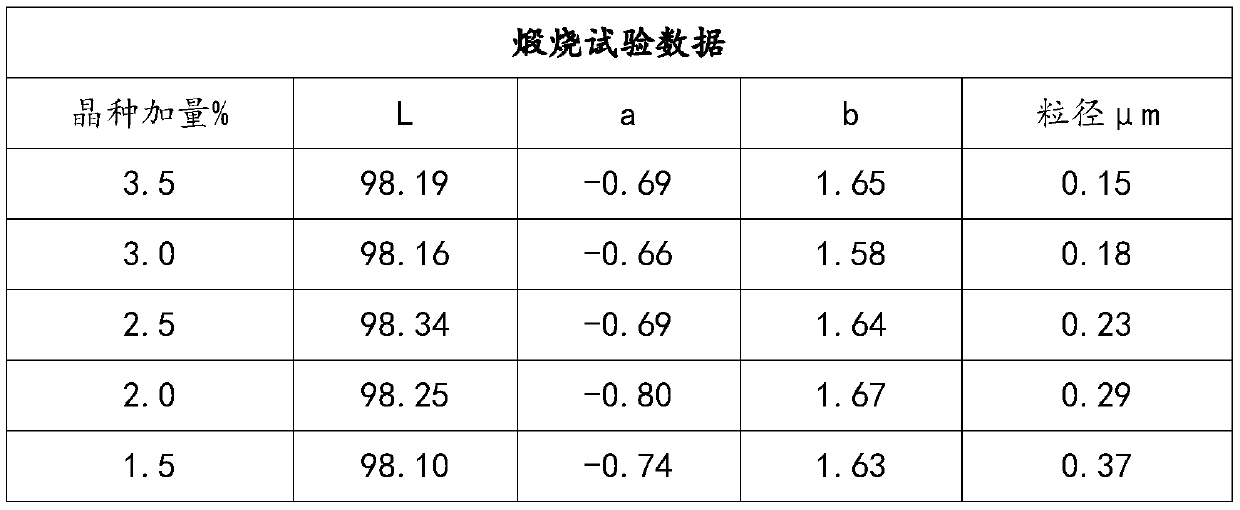

[0021] A method for improving the whiteness of titanium dioxide by adjusting particle size, comprising the steps of:

[0022] (1) Pulverization: pulverizing ilmenite to form titanium ore powder;

[0023] (2) Acid hydrolysis: Use concentrated sulfuric acid to decompose ilmenite to make a black titanium solution containing soluble sulfate of titanium; in order to reduce the ferric iron in the black titanium solution to bivalent, add excess metal iron powder;

[0024] (3) Sedimentation: After the acid hydrolysis and leaching reduction in the previous step, a flocculant is added to settle the insoluble impurities;

[0025] (4) Thermal filtration: take the clear liquid above the settling tank, remove the suspended solids by a plate and frame filter press, and obtain clarified titanium liquid;

[0026] (5) Crystallization: the ferrous ion crystals in the titanium liquid are separated by vacuum crystallization or freeze crystallization;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com