Oil repellent finish of fabric

A finishing agent and fabric technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of high oil stain binding fastness and difficult cleaning, and achieve the goal of preventing infiltration and combined staining, improving product quality, and improving functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

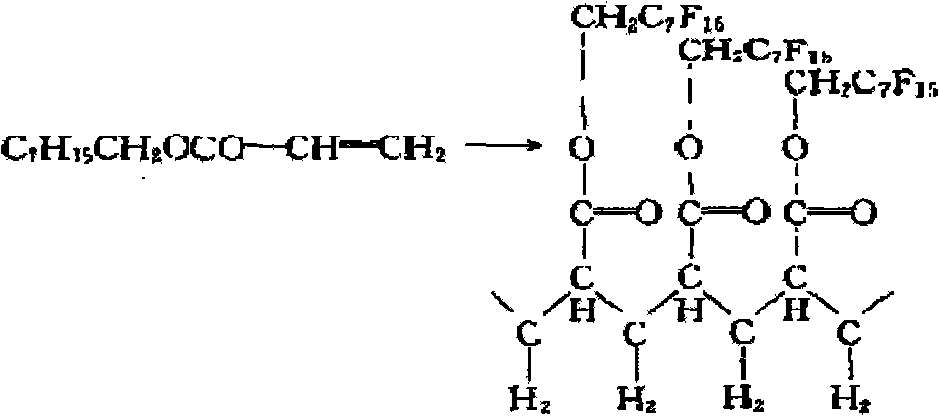

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Take 35g of fluorocarbon acrylate resin, 2g of bone glue, 3g of water-soluble silicone, and 1.08g of triethylamine, add deionized water to one liter at room temperature, stir evenly, and adjust the pH to 4.5 with sodium hydroxide -5.5, prepare this finishing agent solution with a volume of 1L.

Embodiment 2

[0017] Example 2: Take 45g of fluorocarbon acrylate resin, 2.5g of acrylic acid, 4g of water-soluble silicone, and 1.8g of triethylamine, add deionized water under normal temperature conditions and stir evenly, adjust the pH to 4.5-5.5 with sodium hydroxide, Prepare 1L volume of this finishing agent solution.

Embodiment 3

[0018] Embodiment 3: Take 40g of fluorocarbon ester resin, 1g of bone glue, 2g of acrylic acid, 4g of water-soluble silicone, and 1.8g of triethylamine, add deionized water under normal temperature conditions and stir evenly, adjust the pH to 4.5- 5.5, Prepare the finishing agent solution in 1L volume.

[0019] The finishing agent finishing adopts the dipping process: dipping (pour the above-mentioned finishing agent solution prepared into the industrial rolling car storage tank, the working liquid is 1-3 times the weight of the fabric, and dipping for 5-10 minutes)→Roll ( Input the impregnated fabric into the upper and lower two rollers of the industrial rolling machine, the working pressure is 0.5-1 MPa, under the pressure, the working hydraulic pressure on the fabric is evened out, and the excess working liquid is pressed off) → pre-drying (110 ℃, 3min) → heat treatment and baking (140±50℃, 3min), home textiles with excellent oil repellency and easy decontamination can be o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com