Electric appliance fire detector

A technology of fire detectors and electrical appliances, applied in the field of monitoring detectors, can solve problems such as easy to absorb dust monitoring, untimely fire, etc., to reduce the threat of life and property, and reduce the effect of reducing detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

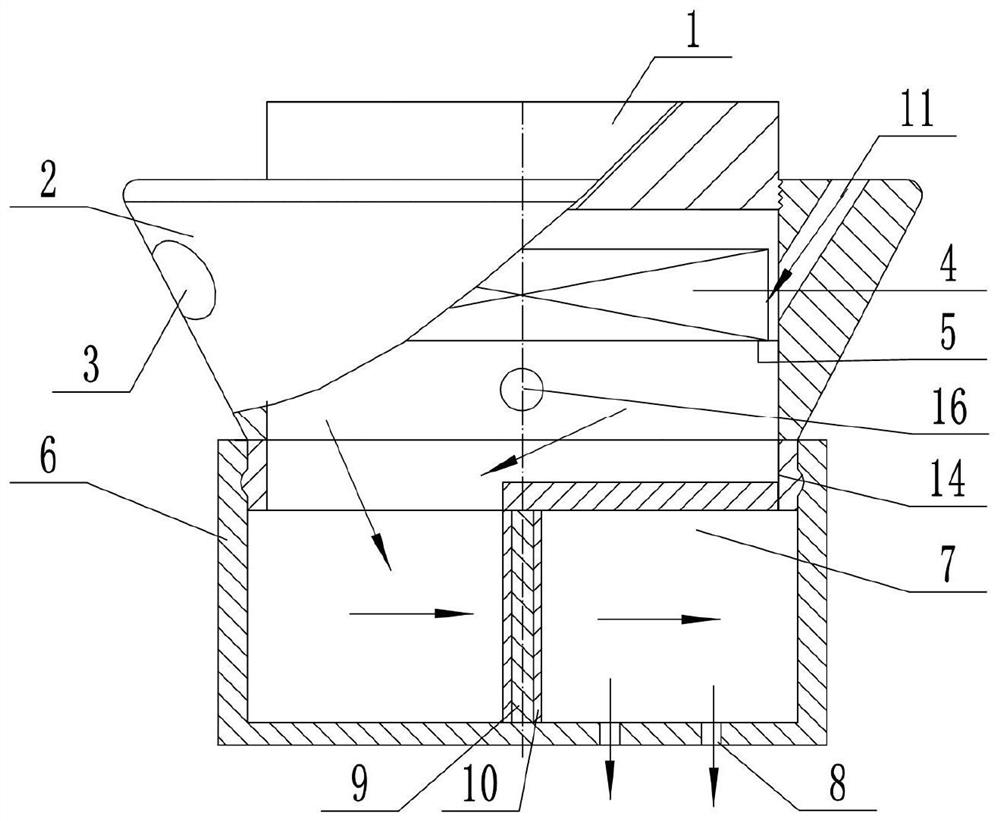

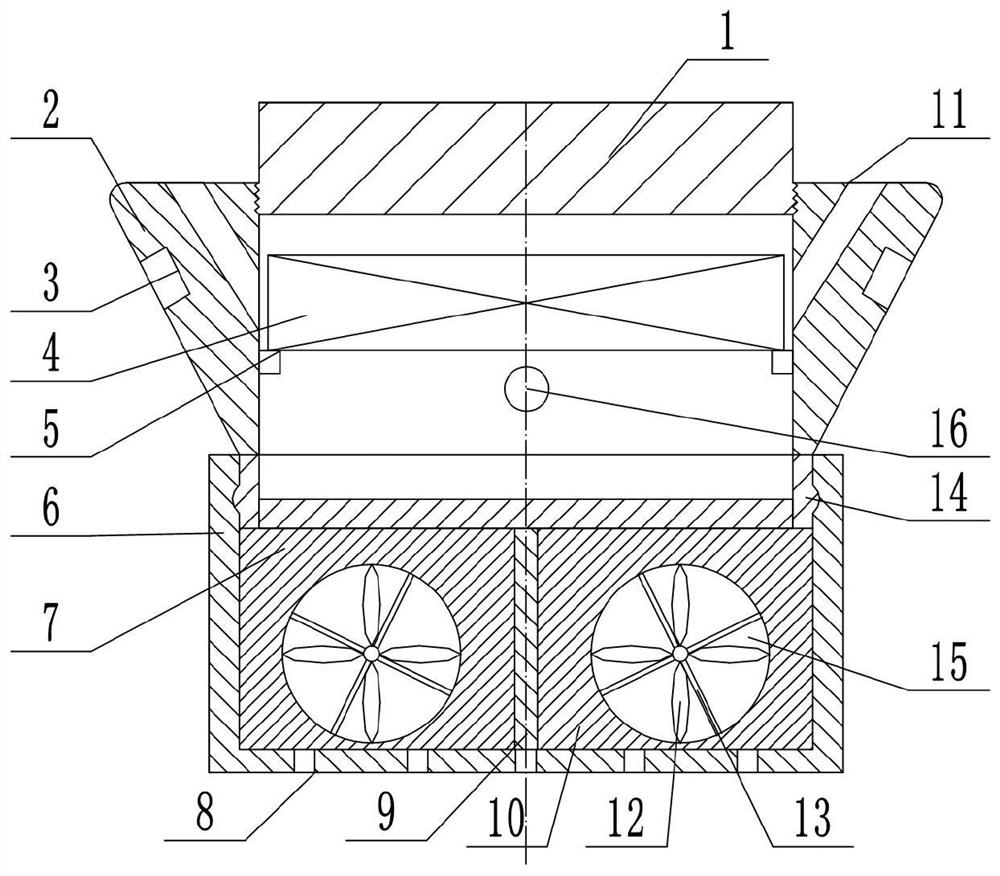

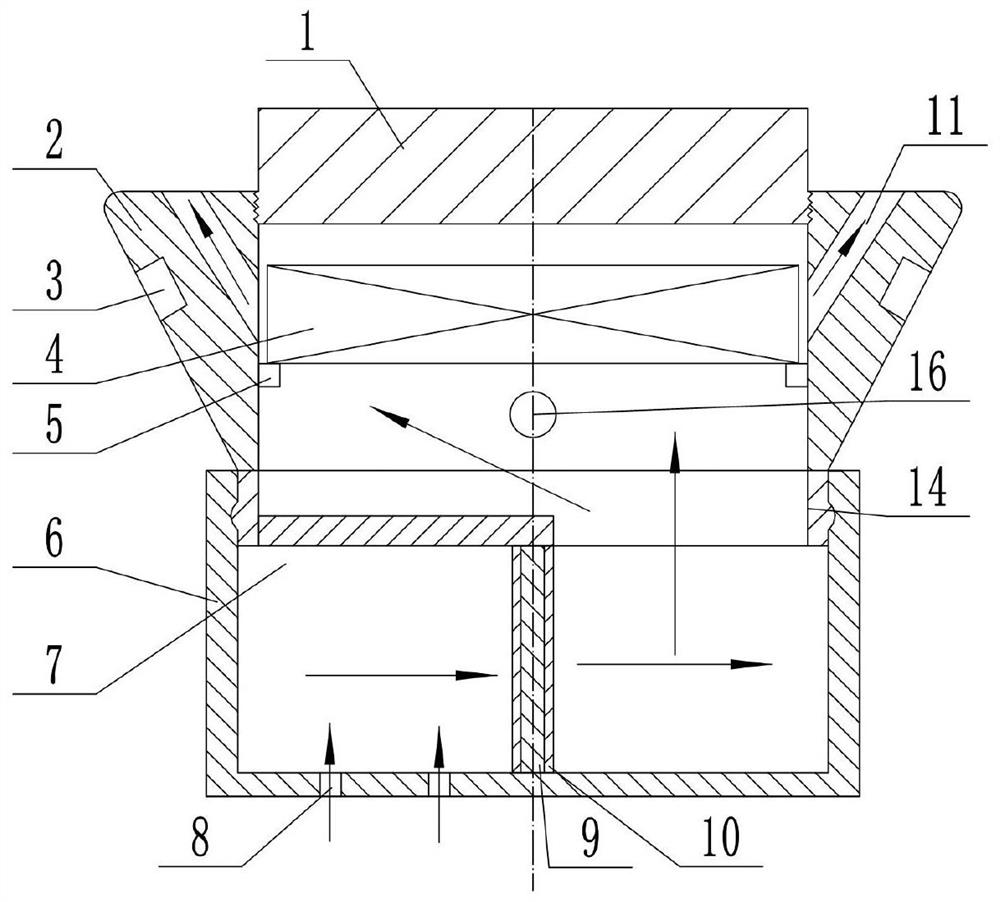

[0037] An electrical fire detector includes an installation support block 1, a housing 2, an alarm device 4 and a smoke sensor probe 16 all arranged in the housing 2, the outer wall of the lower end of the installation support block 1 is provided with external threads, and the housing A cylindrical cavity is coaxially arranged inside the body 2. The housing 2 is a round platform, and its large end is coaxially threaded with the lower end of the installation support block 1 through the internal thread at the upper end of the cavity, and its small end is coaxially threaded with the lower end of the mounting support block 1. The shaft is fixedly connected with a connecting cylinder 14, and an alarm device 4 is installed on the upper part of the cavity. A cylinder 6, the cylinder 6 is rotatably mounted on the connecting cylinder 14, and a fan assembly is fixedly arranged inside the cylinder 6;

[0038] The upper end of the housing 2 is provided with a plurality of ventilation hole...

Embodiment 2

[0050] On the basis of Embodiment 1, an installation snap ring 5 for placing the alarm device 4 is fixedly arranged on the inner wall of the middle part of the cavity.

[0051] The installation snap ring 5 is arranged on the inner wall of the cavity, which is convenient for placing the alarm device 4 .

Embodiment 3

[0053] Further, an annular protrusion is provided on the outer peripheral surface of the connecting cylinder 14, and the cylindrical body 6 is rotatably matched with the annular protrusion of the connecting cylinder 14 through an annular groove on its inner wall, so that the cylindrical body 6 is rotatably mounted on the on the connecting cylinder 14.

[0054] Through the arrangement of the annular protrusion and the annular groove, the rotating connection structure between the cylinder body 6 and the connecting cylinder 14 is more specific, which is convenient for those skilled in the art to implement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com