External wallboard with waterproof structures for transformer substations

A technology for waterproof structures and substations, applied in antifouling/underwater coatings, building components, building structures, etc., can solve the problems of substation safety hazards, weak antistatic ability of external wall panels, and easy safety hazards, etc. Small size, improved hydrophobicity and self-cleaning properties, and improved heat retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

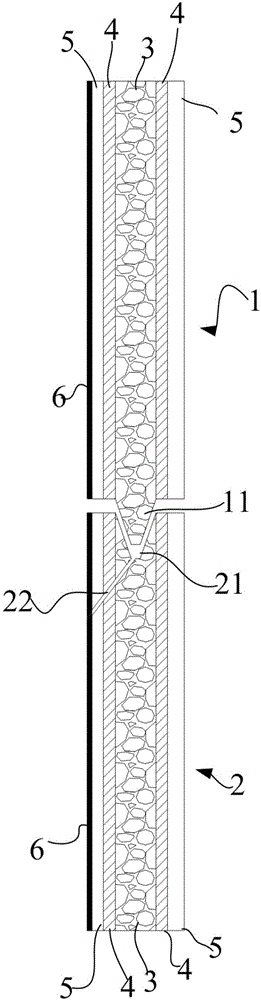

[0024] Example 1, such as figure 1 As shown, this embodiment provides an exterior wall panel with a waterproof structure for a substation, including an upper prefabricated panel and a lower prefabricated panel that are mutually matched up and down, and a protrusion for inserting into the lower prefabricated panel is provided at the bottom of the upper prefabricated panel , the lower prefabricated slab is provided with a groove for matching the protrusion, and the protrusion is set in a trapezoidal shape. The connection between the upper and lower prefabricated slabs is completed by inserting the protrusions into the groove. Considering that when the upper and lower prefabricated slabs are connected, There must be a certain gap, and this gap is that the bottom of the groove that may enter the groove in the future is provided with a drain pipe. In this embodiment, the drain pipe is arranged downward from the inside to the outside, so that the water that enters the gap can be easi...

Embodiment 2

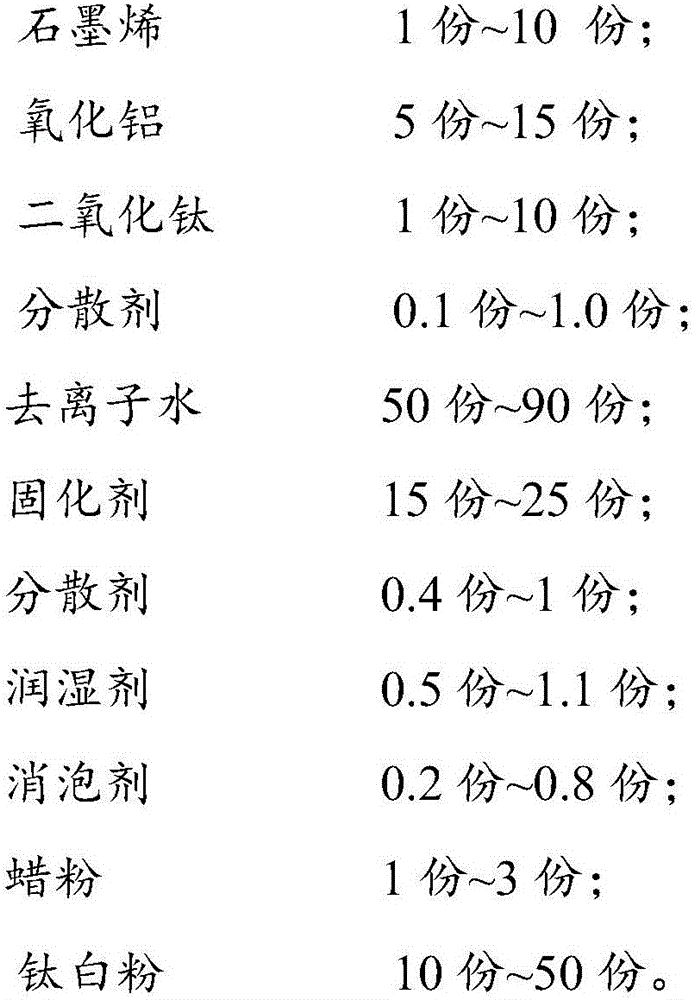

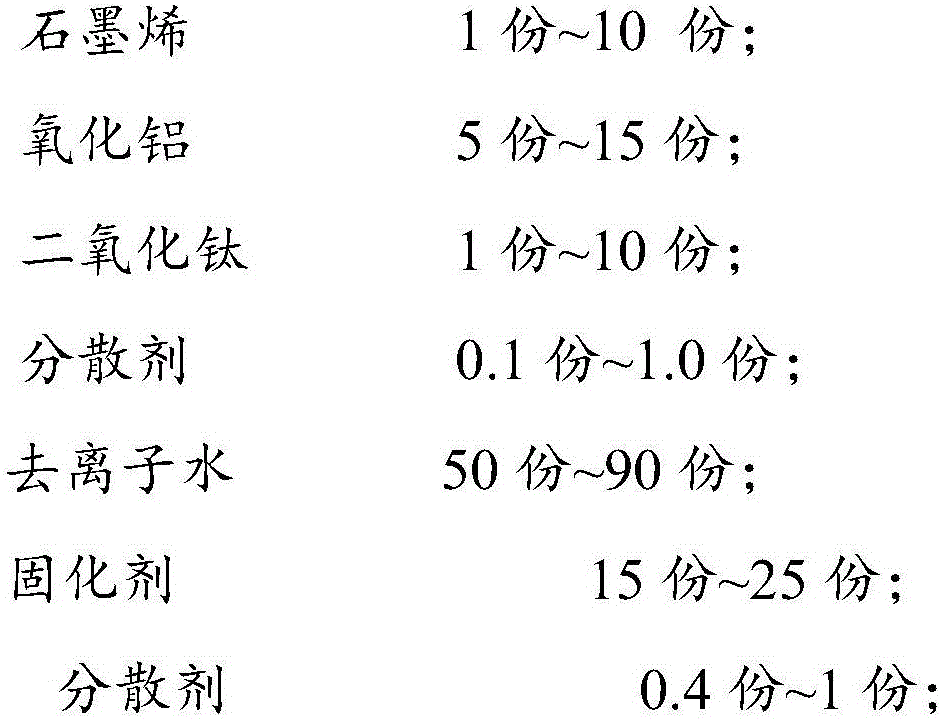

[0027] Embodiment 2, present embodiment provides another kind of coating that exterior wall panel coating layer is used

[0028] The coating includes the following active ingredients in parts by weight: 10 parts of graphene; 15 parts of aluminum oxide; 1 part of titanium dioxide; 0.1 part of dispersant; 90 parts of deionized water; 25 parts of curing agent; parts; 8 parts of defoamer; 3 parts of wax powder; 50 parts of titanium dioxide. Among them, the curing agent is a water-soluble isocyanate-containing polymer; the dispersant is potassium polyacrylate; the wetting agent is a mixture of fatty acid ester sulfate, alkylphenol polyoxyethylene ether, and polyoxyethylene modifier. Mixture, the mixing ratio is 1:2:1; the defoamer is any one of the organosilica modifiers; the dispersant is potassium polyacrylate; the titanium dioxide is rutile titanium dioxide, and the wax powder is polytetrafluoroethylene Vinyl fluoride.

[0029] This embodiment utilizes the characteristics of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com