Processing method of fiber strengthening composite corrugated board

A corrugated cardboard and processing method technology, which is applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems such as the difficulty of greatly improving the mechanical properties and bearing capacity, the inability to ensure the overall strength of the carton, and the inability to be widely used, etc. To achieve the effect of easy separation and recycling, improved stacking speed and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

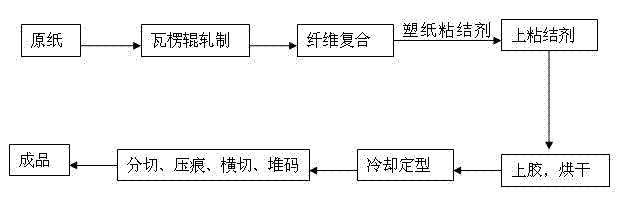

[0025] to combine figure 1 , in the present embodiment, the processing method of fiber-reinforced composite corrugated cardboard is as follows:

[0026] ① The base paper is rolled by corrugating rollers to form corrugations on the base paper, which is called corrugated paper.

[0027] ② The fiber is pressed on the inner side of a layer of cardboard paper in the form of wire, and plastic-paper binder is applied. The plastic-paper binder is a mixture of additives, borax, liquid alkali, corn starch and water, and the mixing mass ratio is additive : Borax: Liquid caustic soda: Corn starch: Water=1:3:5:16:25, the additive is a bridge erecting machine and a stabilizer mixed according to the mass ratio of 1.67:0.33, the borax is industrial borax, and the liquid caustic is The mass percentage is 32% NaOH solution, the cornstarch is food-grade cornstarch; the fiber is high-strength polyester industrial yarn (the manufacturer is Zhejiang Guxiandao New Material Co., Ltd., the model is G...

Embodiment 2

[0033] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that the fiber is nylon, and the fiber is pressed on the inner side of a layer of cardboard paper in the form of a grid, and the grid density is 16-24 holes / m 2 .

Embodiment 3

[0035] to combine figure 1 , in the present embodiment, the processing method of fiber-reinforced composite corrugated cardboard is as follows:

[0036] ① The base paper is rolled by corrugating rollers to form corrugations on the base paper, which is called corrugated paper.

[0037] ② The fiber is pressed on the inner side of a layer of cardboard paper and the core paper in the form of wire, and plastic-paper binder is applied. Among them, the additives in the composition of the plastic-paper binder are bridging machine and stabilizer according to the mass ratio of 1 : 1 mixed, the liquid caustic soda is 30% NaOH solution in mass percentage, and other parameters are the same as the plastic paper binder in Example 1; the fiber is high-strength polyester industrial yarn (Zhejiang Guxiandao New Material Co., Ltd. , the model is GHT-3330 / 384), and its added density is 2 pieces / m 2 , the bonding time is 30 seconds, the bonding temperature is 60°C, and the bonding pressure is 8N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com