Multifunctional graphite interlayer compound as well as preparation method and application thereof

A graphite interlayer and compound technology, which is applied in coatings, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reduced electromagnetic shielding effectiveness, achieve increased product, increased absorption loss, and improved thermal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

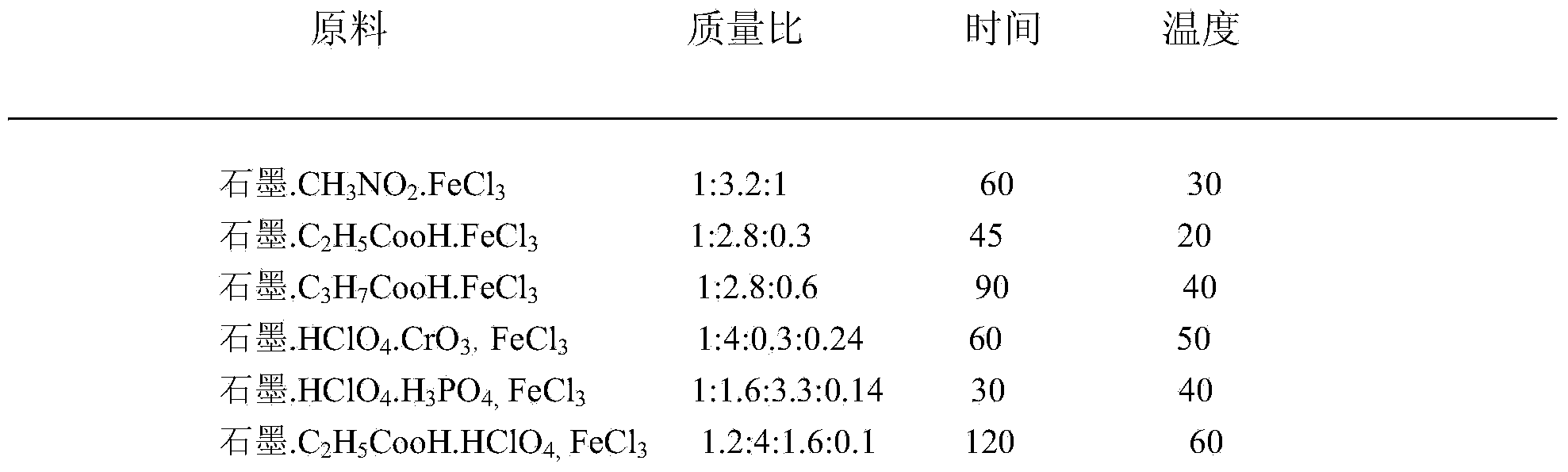

Embodiment 1

[0028] This embodiment adopts 100 mesh, carbon content > 99% natural flake graphite, with CrO 3 , CH 3 NO 2 As a mixed oxidant by chemical oxidation method according to graphite: CH 3 NO 2 : FeCl 3 : CrO 3 =1:3.2:1:0.4 mass ratio, add the above raw materials into the reaction kettle equipped with reflux condensing device and stirrer under constant stirring. Keep a constant temperature of 30°C in the kettle, stir at a speed of 100r / min for 60min, wash the solution until it is colorless, and measure the pH value as neutral. Dry at 60° C. for 5 hours to obtain an interlayer compound.

[0029] The above is the use of FeCl 3 Expandable graphite formed as an intercalation agent. The expansion volume is large, the number of micropores is large, and the micropore structure parameters are relatively uniform. FeCl 3 Intercalation increases the magnetic properties of graphitic intercalation compounds. FeCl when GIC is expanded at high temperature 3 Iron oxides, iron oxides (Fe...

Embodiment 2

[0049] In this example, the flexible graphite powder produced in Example 1 is used according to Table 3, and different polymers are used as base materials to make antistatic and broadband anti-electromagnetic wave functional masterbatches with a mass ratio of 1:4. First put it into the high-speed disperser, put in 1%-2% titanate coupling agent mixed with silicate coupling agent (mass ratio 1:1) to activate the surface, the speed is 500r / min, the time is 30mins, and the temperature is 100 ℃. After discharging, put it into the mixer, (at this time, the temperature should be set according to different base materials, as shown in Table 2), and add 5% POE and 1% antioxidant for mixing until it is evenly formed into agglomerates. Put the transport vehicle into the twin-screw granulator, set the speed requirements of the twin-screw granulator according to the temperature of each zone in the table (as shown in the table), and make the functional masterbatch after stretching into strip...

Embodiment 3

[0054] Prepare functional PS special masterbatch and expandable functional PS masterbatch.

[0055] In this embodiment, the flexible graphite powder obtained in Example 1 is firstly washed with an organic solvent and placed in a centrifuge to be centrifuged and dried, and then placed in a reaction kettle, and deionized water: anionic surfactant, PVA: graphite =20:1:1, at a temperature of 70°C and a rotational speed of 300r / min, after 7 hours, suction filtration, and centrifugal drying to obtain activated flexible graphite.

[0056] Suspension polymerization is carried out with deionized water and styrene monomer, oil phase and water ratio of 5:1. First, add deionized water, activated flexible graphite powder, BPO initiator, inorganic dispersant, emulsifier, anhydrous sulfuric acid, etc. into the reaction kettle in turn, and mix and suspend evenly. Polymerization methods and procedures to form polystyrene particles. This PS particle can be used as a multifunctional masterbatc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com