Reciprocating type seed drying device

A drying device and reciprocating technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of difficult to meet processing use, poor drying effect of seeds, and continuous drying processing of difficult seeds with high efficiency and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further describe the present invention, a specific implementation of a reciprocating seed drying device will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

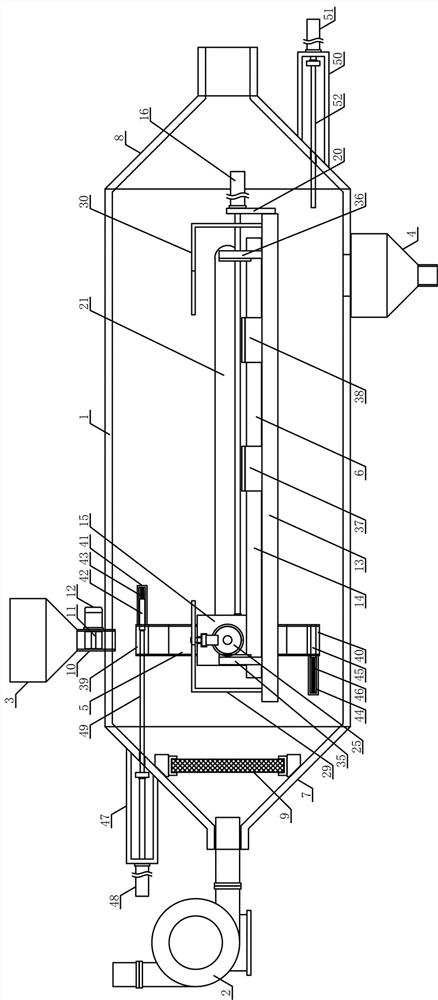

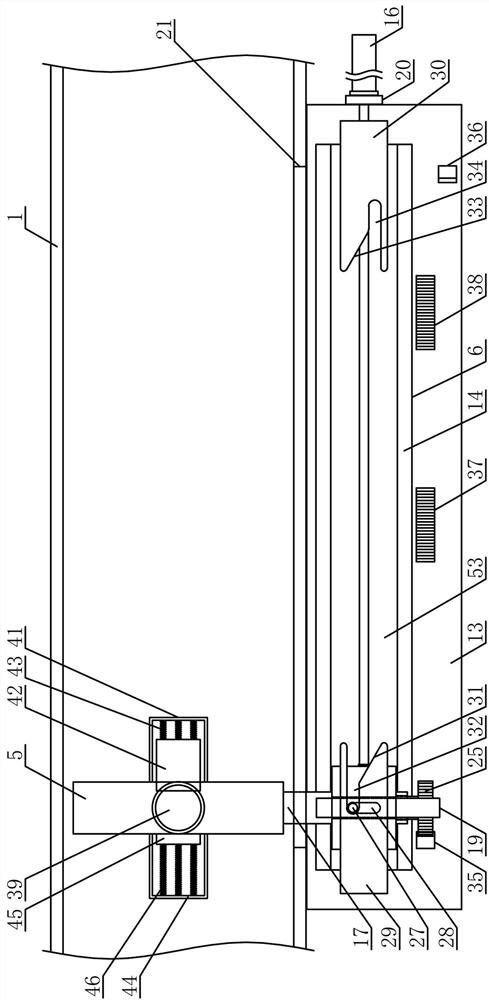

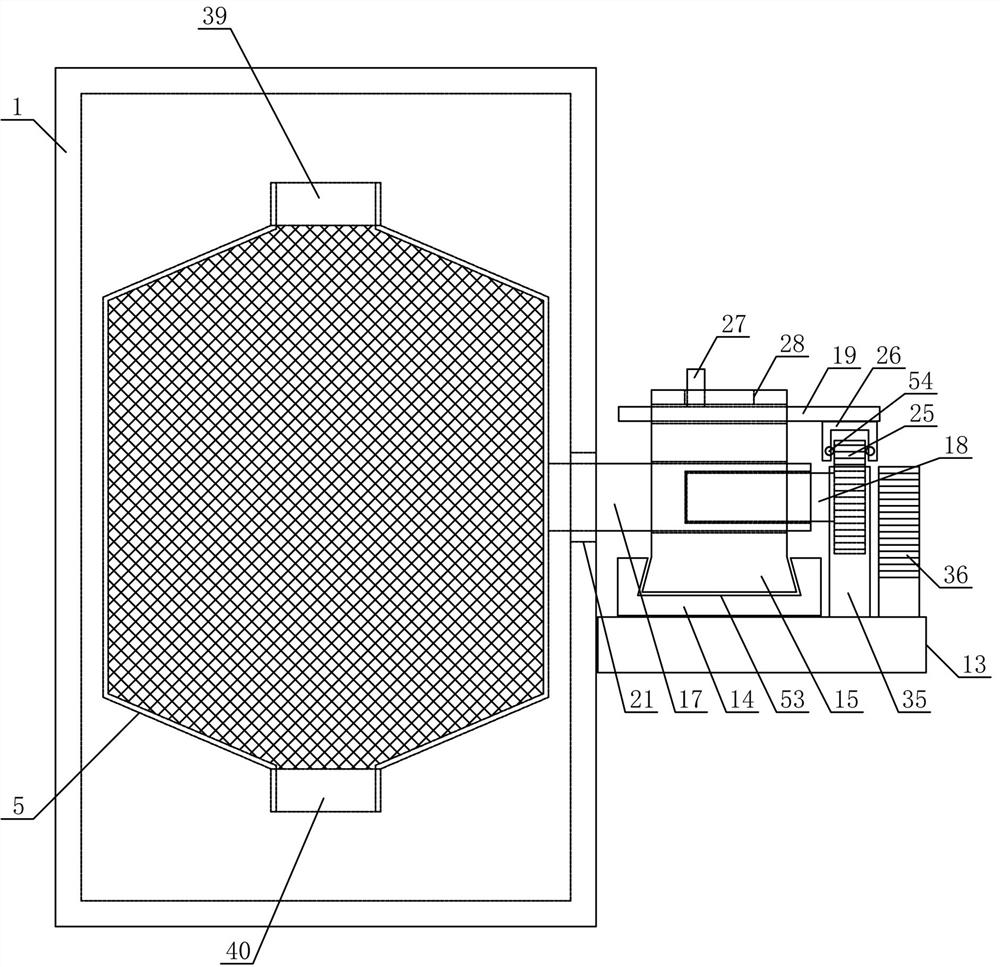

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a reciprocating seed drying device of the present invention includes a seed drying pipeline 1, a drying material blower 2, a seed feeding hopper 3, a seed discharging hopper 4, a drying material storage container 5 and a drying material reciprocating mechanism 6 , the seed drying pipeline 1 is a hollow cuboid structure as a whole, the two ends of the seed drying pipeline 1 are open structures, and the two ends of the seed drying pipeline 1 are respectively fixed and communicated with a drying material inlet hopper 7 and a drying material exhaust hopper 8, The drying materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com