Low-filler antistatic and highly-tough ABS plastic and preparation method thereof

A technology of ABS plastic and filler content, which is applied in the field of antistatic high-toughness ABS plastic and its preparation, can solve the problems of complex process, high filler dosage, ABS toughness influence, etc., and achieves the effects of easy industrialization, simple preparation method, and improved toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

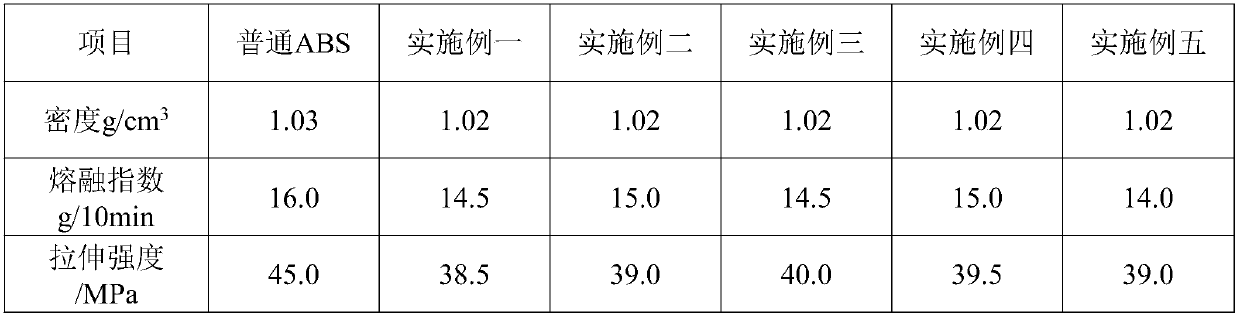

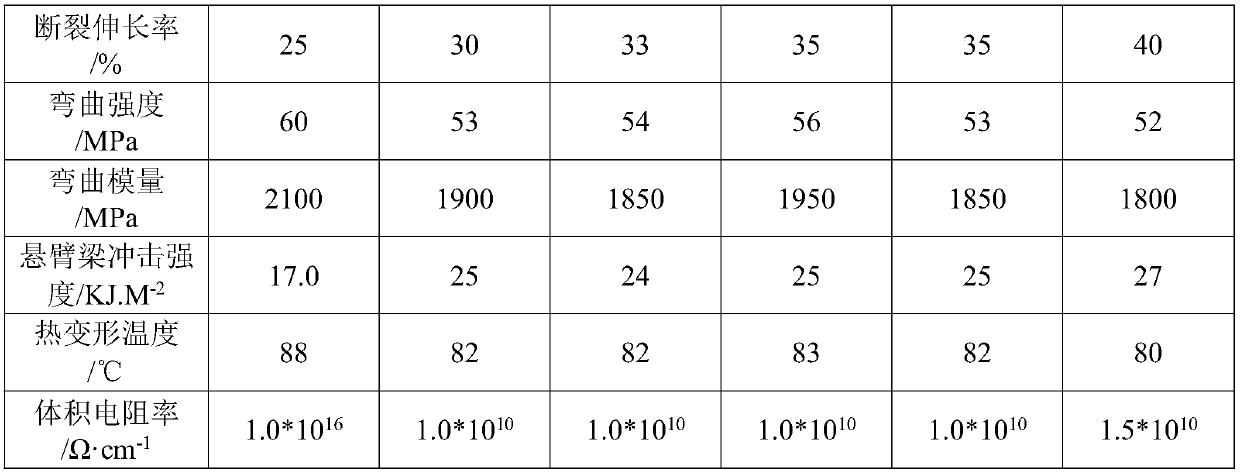

Examples

Embodiment 1

[0026] Step 1, swelling treatment: place 10 parts by weight of natural rubber particles to swell in toluene, the swelling time is 60min, wherein the mass ratio of natural rubber particles to toluene is 1:10;

[0027] Preparation of carbon black suspension: select dimethylformamide (DMF) and deionized water as the dispersion system of carbon black, the mass ratio of dimethylformamide (DMF) and water is 1:1, and the concentration of carbon black is 5mg / mL.

[0028] Step 2, infiltration treatment: adding the swollen natural rubber particles in step 1 to the carbon black suspension, so that the carbon black penetrates into the interior of the natural rubber particles, and the penetration time is 3 hours, and then the natural rubber is washed with deionized water The particles were dried to constant weight to obtain natural rubber particles impregnated with carbon black. The particle size of the carbon black is 20nm.

[0029] Step 3, blending: the natural rubber particles infilt...

Embodiment 2

[0032] Step 1, swelling treatment: 20 parts by weight of natural rubber particles are swelled in toluene, and the swelling time is 60 minutes, wherein the mass ratio of natural rubber particles to toluene is 1:10;

[0033] Preparation of carbon black suspension: select dimethylformamide (DMF) and deionized water as the dispersion system of carbon black, the mass ratio of dimethylformamide (DMF) and water is 1:1, and the concentration of carbon black is 5mg / mL.

[0034] Step 2, infiltration treatment: adding the swollen natural rubber particles in step 1 to the carbon black suspension, so that the carbon black penetrates into the interior of the natural rubber particles, and the penetration time is 3 hours, and then the natural rubber is washed with deionized water The particles were dried to constant weight to obtain natural rubber particles impregnated with carbon black. The particle size of the carbon black is 40nm.

[0035] Step 3, blending: the natural rubber particles ...

Embodiment 3

[0038] Step 1, swelling treatment: 30 parts by weight of natural rubber particles are swelled in toluene, the swelling time is 60min, wherein the mass ratio of natural rubber particles to toluene is 1:10;

[0039] Preparation of carbon black suspension: select dimethylformamide (DMF) and deionized water as the dispersion system of carbon black, the mass ratio of dimethylformamide (DMF) and water is 1:1, and the concentration of carbon black is 5mg / mL. The particle size of the carbon black is 30nm.

[0040] Step 2, infiltration treatment: adding the swollen natural rubber particles in step 1 to the carbon black suspension, so that the carbon black penetrates into the interior of the natural rubber particles, and the penetration time is 3 hours, and then the natural rubber is washed with deionized water The particles were dried to constant weight to obtain natural rubber particles impregnated with carbon black.

[0041] Step 3, blending: the natural rubber particles infiltrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com