Corn thresher for agricultural product processing

A technology of agricultural product processing and threshing machine, which is applied in threshing equipment, agricultural machinery and implements, agriculture, etc., and can solve problems such as low work efficiency, time-consuming and labor-intensive work, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

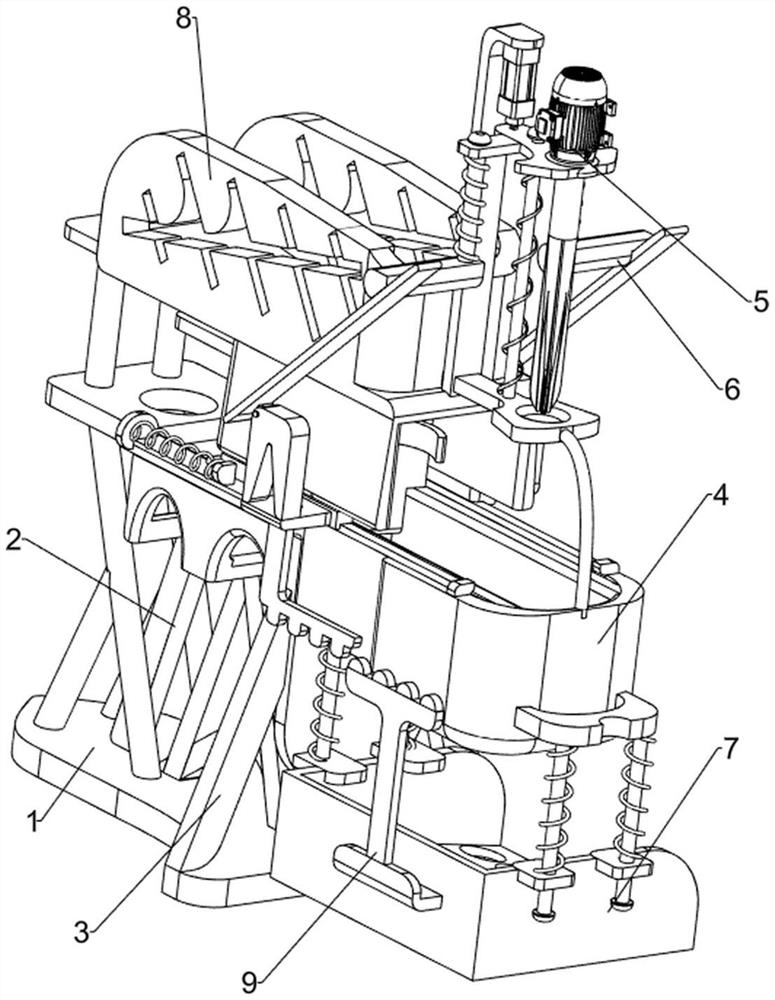

[0068] A corn thresher for agricultural product processing, such as figure 1 As shown, it includes a base 1, a support block 2, a first fixing frame 3, a pushing mechanism 4 and an extruding mechanism 5. The base 1 is provided with a support block 2, and the left and right sides of the front part of the base 1 are provided with first fixing frames. Frame 3, a push mechanism 4 is connected between the top of the support block 2 and the top of the first fixed frame 3, and the push mechanism 4 is provided with an extruding mechanism 5.

[0069] When people need to thresh the corn, first people put the corn in the pushing mechanism 4, then make the pushing mechanism 4 run, the pushing mechanism 4 makes the corn move forward, and people make the extruding mechanism 5 run at the same time. When moving forward, people make the pushing mechanism 4 stop running, and then the corn stops moving, and the squeezing mechanism 5 pushes the corn downwards, and the corn moves down a certain di...

Embodiment 2

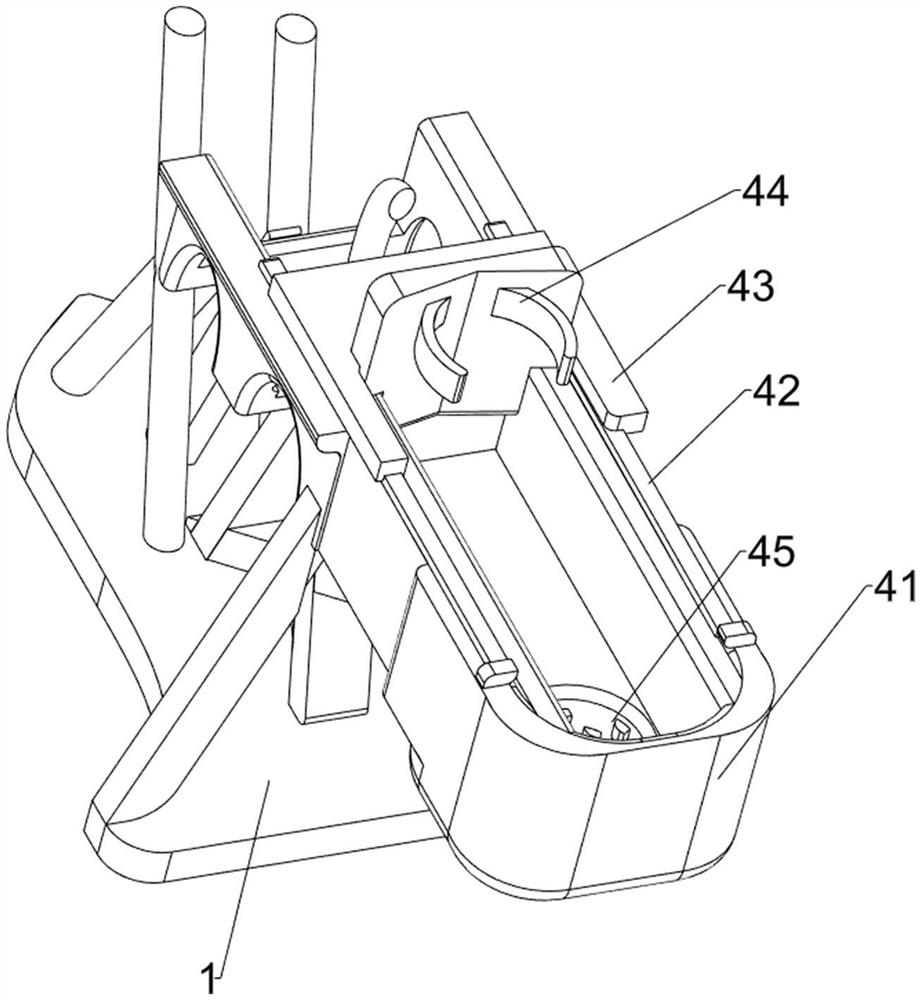

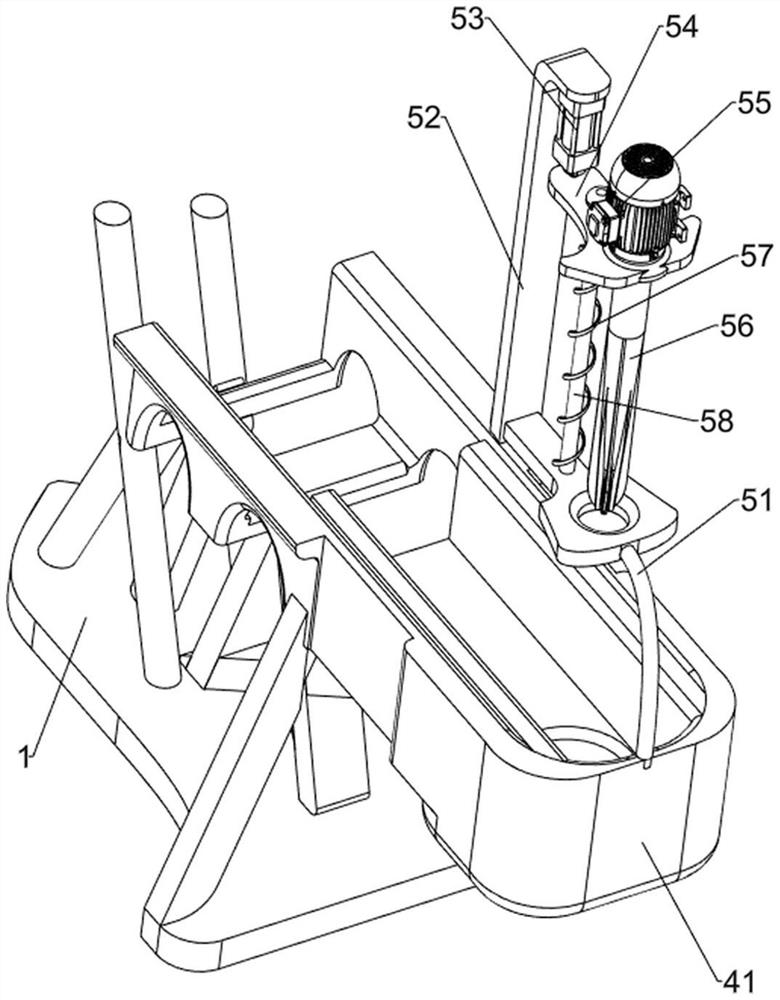

[0071] On the basis of Example 1, such as figure 2 and image 3 As shown, the pushing mechanism 4 includes a pushing frame 41, a first slide rail 42, a first sliding frame 43, a first pushing frame 44 and an extrusion ring 45, and the top of the support block 2 is connected to the top of the first fixed frame 3. There is a push frame 41, the top left and right sides of the push frame 41 are provided with first slide rails 42, and the first slide frame 43 is slidably connected between the two first slide rails 42, and the left and right sides of the first slide frame 43 front side Both sides are provided with a first push frame 44, and the inside of the lower side of the front part of the push frame 41 is provided with an extruded ring sleeve 45.

[0072] People put corn between the two first push frames 44, then manually push the first slide frame 43 forward, so that the first slide frame 43 slides forward on the first slide rail 42, while the first slide frame 43 moves Dri...

Embodiment 3

[0076] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a reciprocating mechanism 6 is also included, and the reciprocating mechanism 6 includes a connecting block 61, a roller 62, a diagonal bar 63, a second fixed block 64, a second spring 65, a second sliding rod 66, a sliding sleeve 67, a third fixing Block 68 and the 3rd spring 69, first sliding frame 43 left and right sides front parts are all provided with connecting block 61, and the connecting block 61 rear side upper inner side of left and right sides is all rotatably provided with roller 62, pushes block 54 left and right sides The rear portion is provided with a sliding sleeve 67, and the inside of the sliding sleeve 67 on the left and right sides is slidably provided with a second sliding rod 66, and the bottom of the second sliding rod 66 on the left and right sides is provided with a second fixed block 64. A second spring 65 is wound around the second sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com