Iron pan raw material handle manufacturing equipment

A technology for iron pans and handles, which is applied in the field of iron pan raw material handle manufacturing equipment, which can solve problems such as irregular curvature of handles, affecting manufacturing efficiency, and people's injuries, and achieves the effect of consistent curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

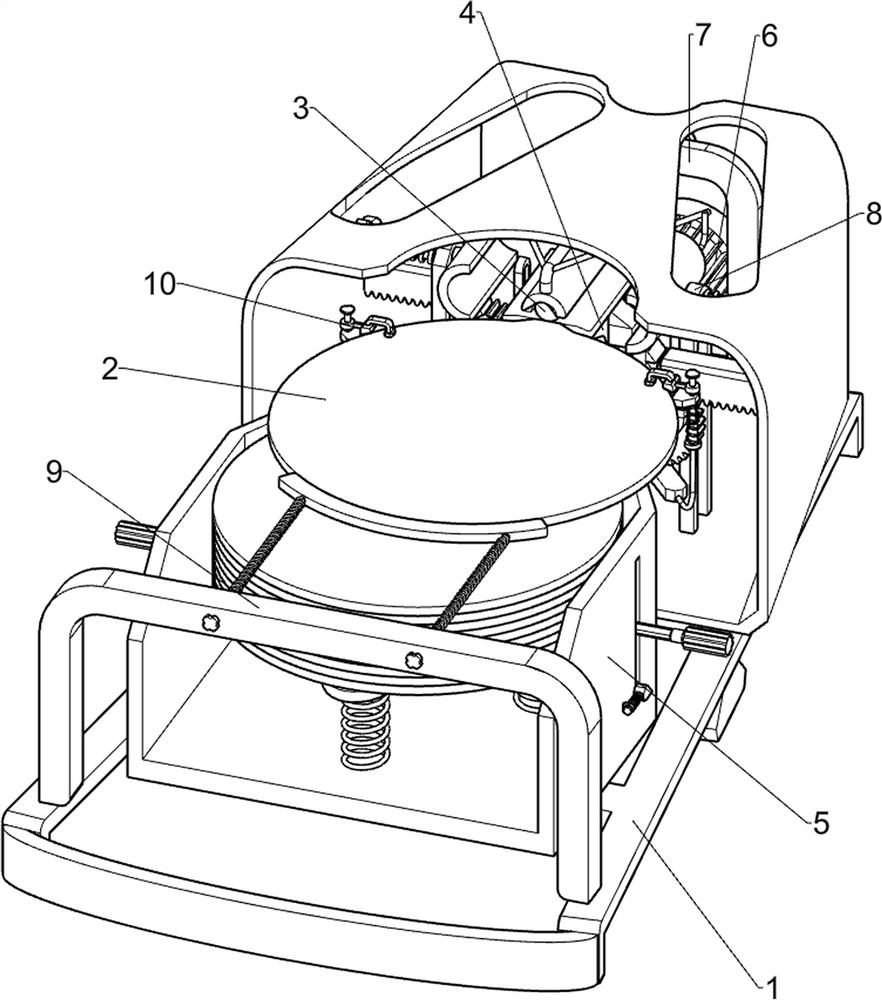

[0026] A kind of iron pan raw material handle making equipment, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base 1, an iron pan plate 2, an extruding rod 3, a first extruding plate 4, a bearing mechanism 5, a driving mechanism 6 and a push-out mechanism 7. The left side of the base 1 is provided with a bearing mechanism 5, and the bearing mechanism 5 An iron pan plate 2 is placed on the upper part, a driving mechanism 6 is arranged in the middle of the right side of the base 1, a first extruding plate 4 is arranged on the left side of the driving mechanism 6, a push-out mechanism 7 is arranged on the right side of the base 1, and a push-out mechanism 7 is arranged on the left side of the push-out mechanism 7. Squeeze rod 3.

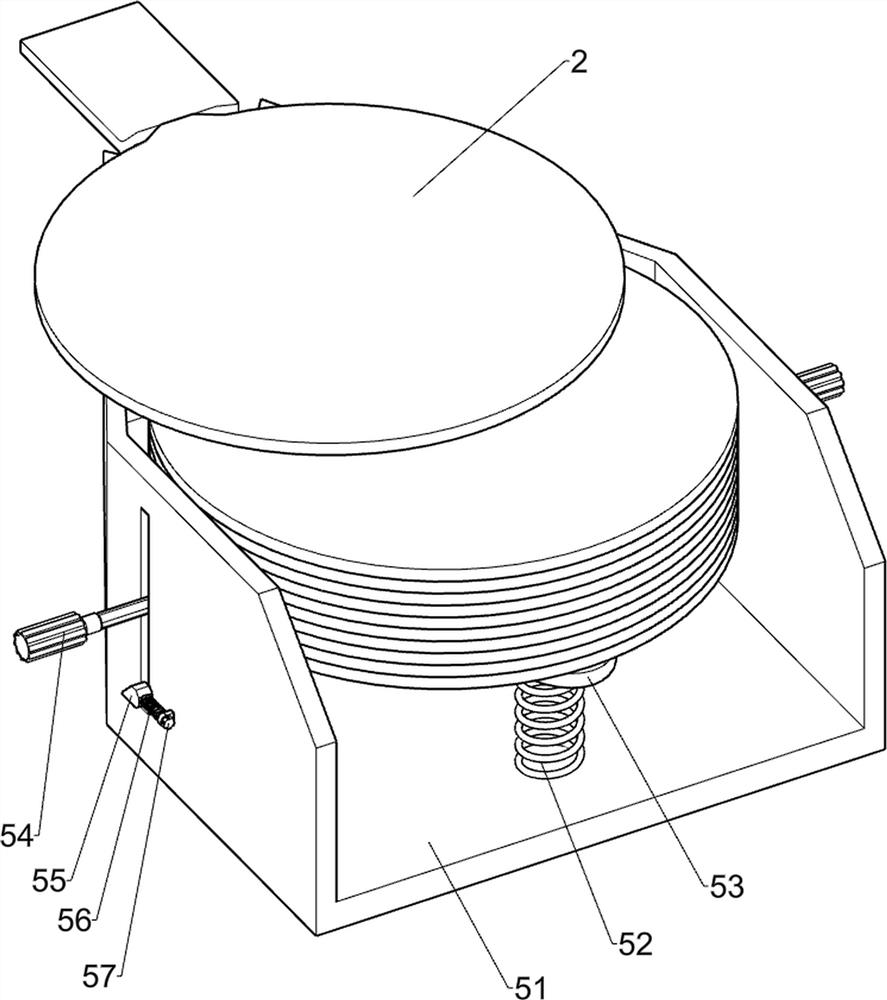

[0027] The bearing mechanism 5 includes a bearing frame 51, a first spring 52, a support plate 53, a handle 54, a first inclined block 55, a second spring 56, a first guide rod 57 and a first mounting block 58, and the...

Embodiment 2

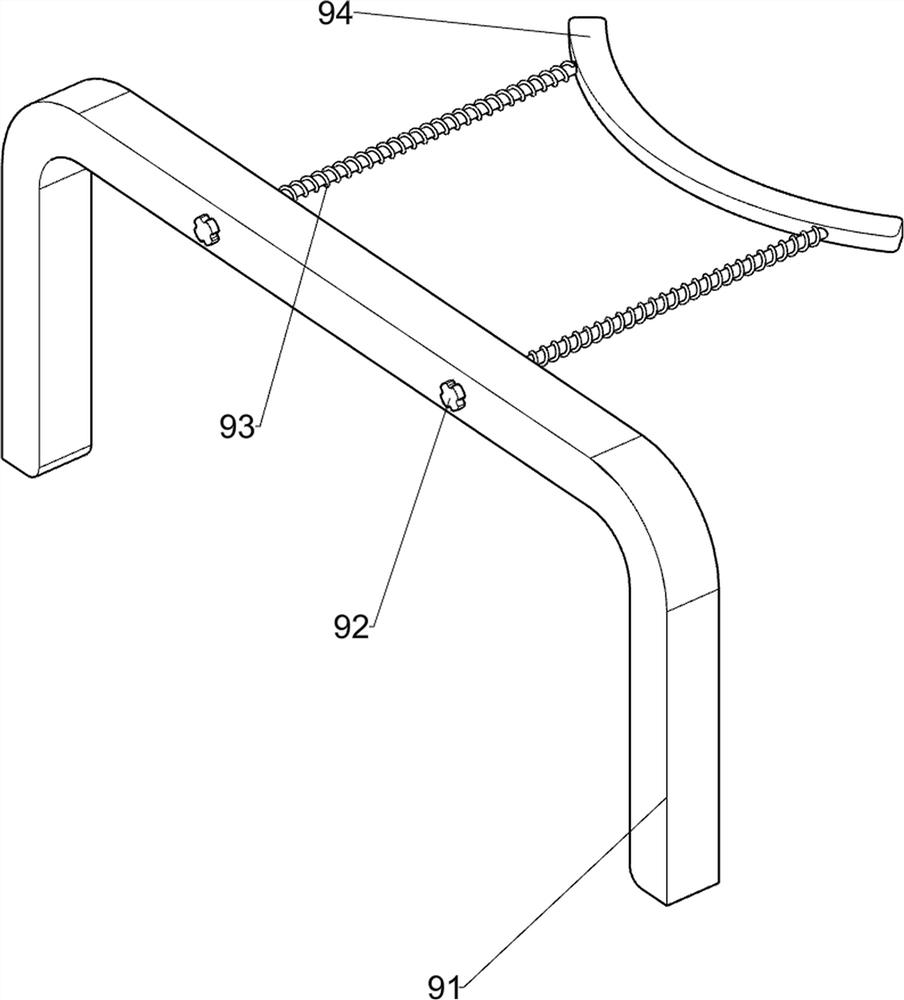

[0032] On the basis of Example 1, such as Figure 5 , Figure 6 and Figure 7 Shown, also comprise extruding mechanism 8, extruding mechanism 8 includes second rotating rod 81, second support frame 82, first gear 83, second ratchet rack 84, spur rack 85, stop bar 86, The fourth spring 87, the second guide rod 88 and the second extruding plate 89, the front and rear symmetrical rotation of the bearing frame 51 right side is provided with the second rotating rod 81, and the second rotating rod 81 is connected with the first rotating mounting block 58 , the right side of the base 1 is provided with a second support frame 82 symmetrically front and back, the second rotating rod 81 is provided with a first gear 83, the first gear 83 on the front side is located in the middle of the second rotating rod 81, and the first gear 83 on the rear side is The gear 83 is positioned at the right side of the second rotating rod 81, the first ratchet bar 64 outside is provided with a second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com